Injection Molding Machine Types

All-Electric Machines

- Key Benefits: Feature highest precision and repeatability, with the lowest energy consumption (typically 30%-50% less than standard hydraulics). Provide the cleanest operation.

- Suitable for: Production environments demanding fast response and high cleanliness. Highly favored by the Medical and Electronics (3C) industries.

Hybrid (Servo-Hydraulic) Machines

- Key Benefits: Balance cost and precision with the energy-saving benefits of a servo drive. Offer robust power and excellent operational stability while significantly reducing running costs.

- Suitable for: Medium-to-high volume stable production of robust parts, such as Automotive components and durable consumer goods.

Standard Hydraulic Machines

- Key Benefits: Represent the most economical choice, offering the lowest initial investment cost. Provide maximum clamping force and are known for their rugged reliability.

- Suitable for: Entry-level customers or applications where initial cost is the primary concern and non-cleanroom environments are acceptable.

Customer focus:

- Global Certification and Compliance:Ensure the machine carries necessary certifications like CE (Europe) and UL (North America). This is crucial for market access and confirms the equipment meets high standards of safety and quality engineering.

- Measurable Energy Efficiency:Prioritize Electric or Hybrid technology. These models can reduce energy consumption by 30% or more, delivering significant operational savings and demonstrating a commitment to sustainability.

- Critical Service and Reliability Support: Provide overseas installation guidance and remote maintenance services. Strong service partnerships can significantly reduce costly unplanned downtime.

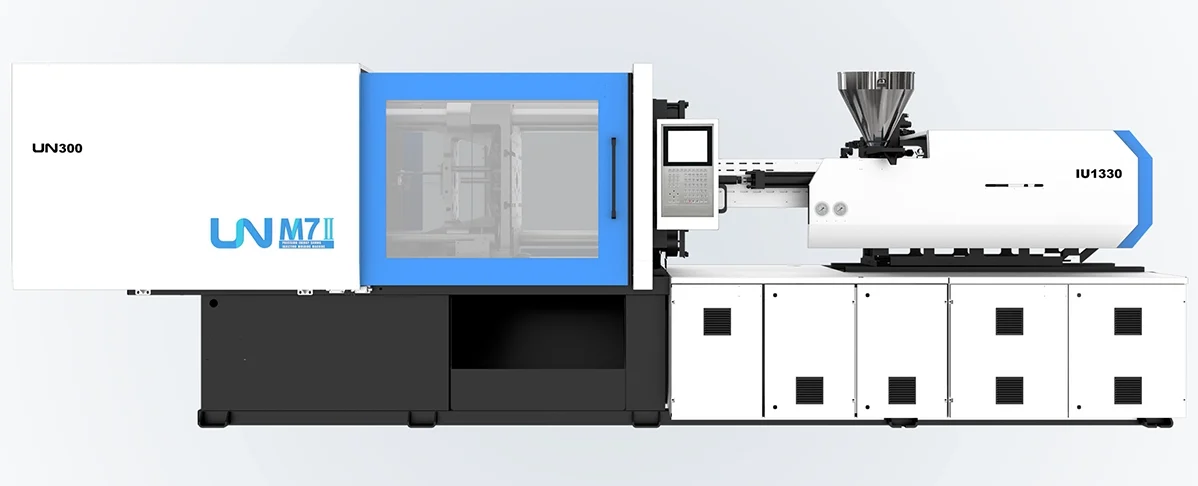

“The 300-ton model is suitable for molds with a projected area of approximately 350-600 cm² and is compatible with demanding engineering materials such as PA, PBT, and large volumes of ABS or PC. The Hydraulic is particularly recommended for its excellent power stability and reduced running costs, making it the best value solution for the automotive and large consumer goods industries.”

Need Help Selecting the Right Machine?

Our injection molding experts can analyze your specific production requirements and recommend the optimal machine configuration for your application.

Technical Specifications (300-Ton Series)

These detailed technical specifications define the precise operational envelope of our 300-ton hydraulic injection molding machines, providing the critical parameters necessary for accurate tooling compatibility and performance prediction based on the standard configuration.

| Clamping Unit | Unit | UN300-M7 | ||

| Clamping Force | kN | 3000 | ||

| Mold Opening Stroke | mm | 600 | ||

| Min. Mold Height | mm | 210 | ||

| Max. Mold Height | mm | 650 | ||

| Max. Daylight | mm | 1250 | ||

| Tie Bar Space (HxV) | mm | 670×620 | ||

| Ejector Stroke | mm | 170 | ||

| Ejection Force | kN | 77 | ||

| No.of Ejector Pin Holes | / | 13 | ||

| Injection Unit | Unit | IU1330 | ||

| A | B | C | ||

| Screw Diameter | mm | 53 | 60 | 68 |

| Screw L/D Ratio | L/D | 22 | 20 | 20 |

| Theoretical Shot Volume | cm³ | 585 | 749 | 962 |

| Shot Weight(PS) | g | 532 | 682 | 876 |

| Injection Rate | g/s | 205 | 263 | 338 |

| Injection Pressure | MPa | 228 | 178 | 138 |

| Plasticizing Capacity (PS) | g/s | 29 | 41 | 57.2 |

| Screw Rotation Speed | rpm | 197 | ||

| General Data | Unit | IU1330 | ||

| Heater Power | kW | 17/19 | ||

| Motor Power | kW | 31.2 | ||

| Oil Tank Capacity | L | 340 | ||

| Theoretical Weight | t | 9.8 | ||

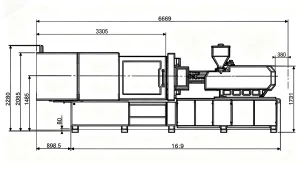

| Machine Dim.(L×W×H) | m | 6.4×1.6×2.1 | ||

- Screw Sizing: The availability of three distinct screw diameters (A/B/C) allows for precision customization. A manufacturer must select the screw size that utilizes 40%-80% of the barrel capacity for their primary part, ensuring optimal melt quality and material residence time.

- Space Utilization: Note the Tie Bar Space (670 × 620 mm) is the ultimate constraint; it must be physically larger than the mold body. The generous Max Mold Height (650 mm) offers flexibility for deeper, more complex tooling.

- Performance Trade-offs: As shown by the data, a smaller screw (53 mm) provides the highest injection pressure (228 MPa) (ideal for precise, thin walls), while the largest screw (68 mm) maximizes shot volume at a lower pressure (ideal for larger, less complex parts).

Access Detailed Technical Specifications

Need precise data for your planning? Contact our expert team to receive comprehensive technical documentation and data sheets for our leading 300 ton injection molding machine models, directly supporting your equipment evaluation process

Applications and Typical Products

The 300 ton injection molding machine class is exceptionally versatile, supporting production across numerous industries and applications. This tonnage range offers an ideal balance of capacity and efficiency for producing medium-sized components that require both structural integrity and consistent cosmetic quality.

Industry Applications

The 300-ton capacity functions as a strategic backbone across key manufacturing sectors, delivering components that require a moderate to high level of complexity and reliable output.

Automotive

- Interior trim elements (consoles, glove boxes)

- Under-hood fluid reservoirs

- Electrical junction boxes

- Structural mounting brackets.

- Balance of Tonnage and Space: Efficiently handles the projected area of interior parts while maintaining cycle speed.

Consumer & Appliance

- Durable appliance housings (e.g., vacuum cleaners)

- Major components for large kitchen equipment

- Electronic device precision enclosures

- Furniture components

- Cosmetic Consistency: Provides the clamping stability and injection control necessary for large, visible parts requiring high aesthetic quality.

Industrial & Infrastructure

- Material handling crates/totes

- Industrial pump and valve bodies

- Electrical enclosures (IP ratings)

- Structural supports and machine covers

- Structural Integrity: Offers the requisite clamping force and injection pressure for processing filled compounds needed in high-stress environments.

Medical & Life Sciences

- Diagnostic equipment housings

- Medium-sized labware racks

- Disposable surgical tray components.

- Repeatability: Often utilizes All-Electric or Hybrid 300T units to meet strict validation and high-repeatability standards.

Material Compatibility

The 300-ton machine’s robust injection unit and configurable screw options provide significant processing latitude, allowing it to handle nearly the entire spectrum of thermoplastic materials.

| Material Category | Common Types | Typical Applications | Critical Processing Considerations |

| Commodity Plastics | PP, PE, PS, ABS | General enclosures, packaging, household goods. | Speed and Efficiency: These materials maximize the machine’s potential for rapid cycle times and high throughput. |

| Engineering Plastics | PC, PA (Nylon), POM, PBT | Functional/structural components, electrical housings, automotive parts. | Temperature and Pressure: Requires machines with sufficient heater power and injection pressure to ensure proper melt homogeneity and mold filling. |

| High-Performance | PEEK, PPS, PEI, PSU | Metal replacement, high-temperature/chemical environments. | Equipment Protection: Requires barrels, screws, and tips made of high-wear, corrosion-resistant materials due to very high melt temperatures. |

| Filled Compounds | Glass-filled, mineral-filled, carbon fiber reinforced | Structural brackets, gears, high-strength housings. | Abrasive Wear: Requires specialized, hardened screws and increased injection pressure to manage the high viscosity and erosive nature of the melt. |

| Specialty Materials | TPE/TPU, PET, bio-based plastics | Soft-touch grips, gaskets, thin-walled bottles. | Customization: May require special screw designs (e.g., barrier screws) and highly precise temperature control for optimal results. |

Conclusion

The 300 ton injection molding machine fundamentally represents a strategic investment for modern plastics manufacturing. Having examined the spectrum of technologies—from All-Electric precision to the Hydraulic stability exemplified by our core models—and evaluated the critical parameters necessary for successful application, the core conclusion stands: this tonnage class offers the optimal intersection of robust production capacity and maximized operational economics.

The decision to acquire must be guided by more than just maximum tonnage. Manufacturers must focus on detailed long-term value, evaluating machine options based on verified energy efficiency, compliance with international certifications, and the guaranteed availability of expert service and support. This systematic approach ensures the final equipment choice directly enhances uptime and product quality.

The 300-ton platform remains central to the industry’s future, continually evolving to integrate enhanced control systems and deliver optimized efficiency. By making a choice that is meticulously informed by both technical specifications and strategic operational goals, manufacturers secure a foundation that delivers high-quality output and a sustained competitive advantage.

Ready to Optimize Your Injection Molding Operations?

Contact our team of injection molding specialists to discuss your specific requirements and discover how a 300-ton machine can enhance your manufacturing capabilities.