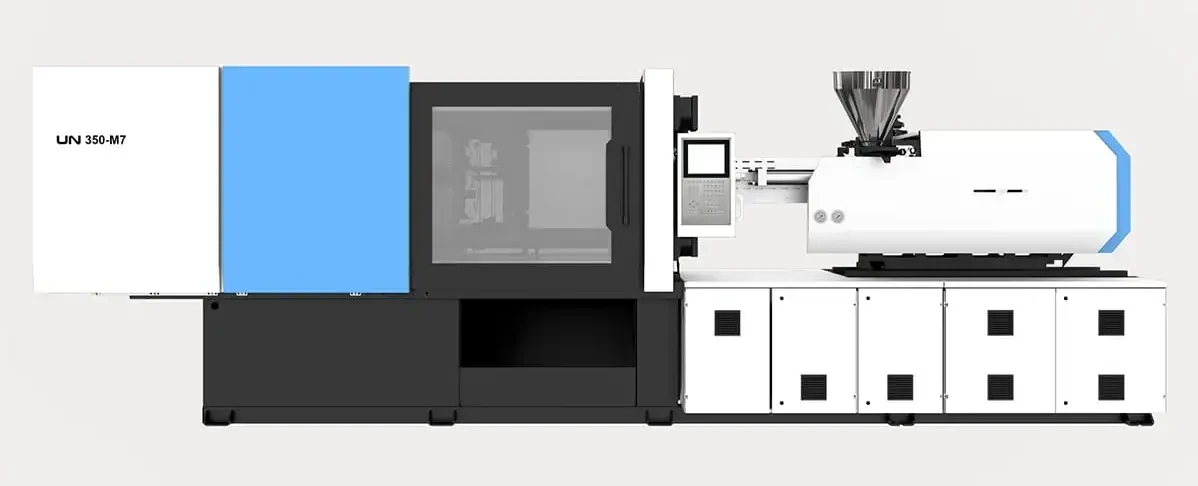

Understanding Tonnage and Machine Basics

The designation “350 ton” precisely defines the maximum clamping force exerted by the machine—the essential mechanism that holds the mold closed. This force directly counteracts the pressure created when molten polymer is injected into the mold cavity. Maintaining this secure seal is critical for two functional outcomes: achieving the required dimensional accuracy and preventing flashing (material escaping at the mold’s parting line).

Clamping Force Mechanics and Part Sizing

The required force for any specific molding application is determined by the component’s projected area (the surface area viewed from the direction of mold opening) and the material’s internal cavity pressure.

A well-established operational guideline suggests a need for 2 to 8 tons of force for every square inch of projected area (310 to 1240 kN per square meter). This range accommodates variations in the material being processed and the overall complexity of the part geometry.

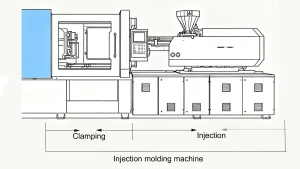

Machine Configuration

The 350-ton machine typically employs a horizontal configuration. The clamping unit secures the mold, utilizing either a powerful hydraulic system or a mechanical toggle system to generate the rated 350-ton lock. The integrated reciprocating screw unit melts and accurately delivers the polymer into the mold cavity, performing the crucial task of material plasticization against the machine’s robust 350-ton resistance.

Basic Operational Cycle

During the basic injection molding cycle—closing the mold, injecting the plastic, allowing cooling, and final part ejection—this specific tonnage ensures the machine reliably manages the process pressures.

Need Help Determining the Right Machine Size?

Our technical experts can help calculate the optimal tonnage for your specific application based on part geometry, material properties, and production requirements.

Detailed Technical Specifications

To properly assess and integrate a 350-ton injection molding machine into a production environment, engineers must reference the machine’s detailed technical profile. The following specifications represent the standard operational parameters typical for equipment in this tonnage class.

| Clamping Unit | Unit | UN350-M7 | ||

| Clamping Force | kN | 3500 | ||

| Mold Opening Stroke | mm | 650 | ||

| Min. Mold Height | mm | 250 | ||

| Max. Mold Height | mm | 710 | ||

| Max. Daylight | mm | 1360 | ||

| Tie Bar Space (HxV) | mm | 710×670 | ||

| Ejector Stroke | mm | 170 | ||

| Ejection Force | kN | 77 | ||

| No.of Ejector Pin Holes | / | 13 | ||

| Injection Unit | Unit | IU1900 | ||

| A | B | C | ||

| Screw Diameter | mm | 60 | 68 | 76 |

| Screw L/D Ratio | L/D | 22 | 20 | 20 |

| Theoretical Shot Volume | cm³ | 834 | 1,071 | 1,338 |

| Shot Weight(PS) | g | 759 | 975 | 1,218 |

| Injection Rate | g/s | 240 | 309 | 386 |

| Injection Pressure | MPa | 226 | 176 | 141 |

| Plasticizing Capacity (PS) | g/s | 52 | 58 | 68 |

| Screw Rotation Speed | rpm | 186 | ||

| General Data | Unit | IU1900 | ||

| Heater Power | kW | 22.5/25 | ||

| Motor Power | kW | 47.50 | ||

| Oil Tank Capacity | L | 430 | ||

| Theoretical Weight | t | 12.10 | ||

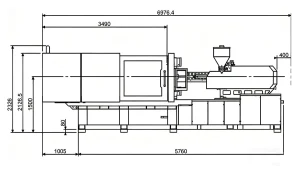

| Machine Dim.(L×W×H) | m | 6.8×1.7×2.1 | ||

Clamping Unit Parameters

The dimensions of the clamping unit directly determine the range of molds a 350-ton machine can run.

- The specified Tie Bar Distance (710 × 670 mm) ensures that molds up to a certain maximum size (e.g., 560 mm square, depending on platen dimensions) can be correctly seated and securely locked.

- The Max. Opening Stroke (650 mm) is a key operational specification; it must be sufficient to allow for the complete removal of the deepest components without interference.

Injection Unit Flexibility

- Selecting a smaller diameter screw (e.g., 60 mm) increases the Maximum Injection Pressure, which is necessary for filling thin-walled or intricate parts.

- Conversely, selecting a larger diameter screw (e.g., 76 mm) increases the Injection Capacity (shot size), suitable for larger, thicker-walled components.

Core Components and Advanced Features

Injection molding machines in the 350-ton class incorporate sophisticated components and integrated technological features to ensure high operational precision, efficient material handling, and consistent part quality.

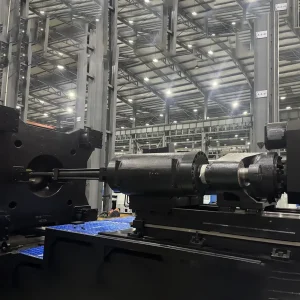

Injection Unit

This system includes the barrel, reciprocating screw, and precision heating elements. These components are engineered for optimal plasticization—the efficient melting and homogenization of a broad spectrum of polymers, from standard resins to engineering-grade thermoplastics.

Clamping System

The mechanism generating the 350-ton lock force utilizes either a toggle system, known for achieving fast cycling speeds through mechanical advantage, or a direct hydraulic system, valued for its flexible control over pressure profiles and platen positioning.

Control System

These machines utilize advanced, processor-based control platforms with user-friendly interfaces. These systems provide real-time monitoring of all process parameters and allow for the accurate, repeatable adjustment of pressure, speed, temperature, and timing throughout the molding cycle.

Advanced Features

Energy Management Systems

To optimize resource consumption, many 350-ton machines employ servo-hydraulic or all-electric drive systems. These configurations reduce power demand by supplying energy only when required, improving operational efficiency compared to conventional hydraulic systems.

Precision Control

Control algorithms allow for the execution of complex, multi-stage injection profiles. These systems manage pressure and speed transitions with high fidelity, which is critical for minimizing internal material stresses and achieving tight dimensional tolerances in the finished part.

Automation Compatibility

Integration with peripheral equipment is facilitated by standardized interfaces. This includes protocols like Euromap 67 for connecting robotic systems and compatibility with data exchange protocols such as OPC-UA for plant-wide data logging and process traceability.

Mold Protection Systems

Integrated sensor arrays monitor mold movement and internal pressure. These specialized systems detect subtle deviations or foreign objects during the closing sequence, enabling immediate machine halt to prevent costly mechanical damage to the tooling.

Practical Applications and Industry Use Cases

The 350-ton injection molding machine maintains a highly versatile position, enabling the production of a wide spectrum of medium-to-large components across diverse industrial sectors.

Automotive Industry

These machines are critical for components requiring a balance of size and material strength, such as interior trim panels, center consoles, and various under-hood parts. The 350 tons of force reliably processes engineering-grade resins (e.g., Polyamides, PC/ABS blends) necessary for structural integrity and stringent surface finish standards.

Durable Goods

In this sector, the machines efficiently manufacture items that require robustness and substantial clamping area, including large appliance housings, furniture supports, and specialized commercial equipment components. The machine’s capacity effectively supports multi-cavity tooling to meet high-volume demands for medium-to-large parts.

Industrial and Logistics

The tonnage is foundational for large-format industrial applications, including the molding of material handling containers, heavy-duty equipment enclosures, and structural fittings that require high resistance to impact and chemical exposure (often utilizing glass-filled polymers).

Medical and Laboratory

The machines produce larger medical device housings, laboratory trays, and hospital furniture components. Precision control systems ensure the necessary consistency and quality required for strict regulatory compliance, often utilizing specialized medical-grade resins (PC, medical-grade PEEK).

Electronics and Telecommunications

These machines produce the larger protective and structural enclosures for computer servers, industrial control cabinets, and communication equipment. The requirement for high-precision molding is met to ensure proper assembly and the integration of features like Electro-Magnetic Interference (EMI) shielding.

| Sector | Typical Components | Critical Material Focus | Key Production Requirement |

| Automotive | Dashboard components, interior trim, bumper supports | PP, PA, ABS, PC/ABS blends | Structural integrity, high output consistency |

| Durable Goods | Appliance housings, storage solutions, furniture parts | PP, PE, PS, ABS | Surface aesthetics, component durability |

| Industrial | Material handling totes, equipment housings, fittings | Glass-filled Nylons, PBT, high-impact polymers | Strength, chemical resistance, dimensional accuracy |

| Medical | Device enclosures, laboratory trays, equipment parts | PC, specialized medical-grade resins | Precision, quality validation, regulatory compliance |

| Electronics | Computer cases, large displays, industrial controls | PC, ABS, flame-retardant grades | Assembly features, heat management, tolerance control |

Case Study

A production facility utilized a 350-ton machine to manufacture large door panel substrates with complex geometries. The combination of substantial clamping force and precise management of injection pressure profiles yielded consistent part dimensions across all cavities. The result demonstrated an improvement in production velocity and part quality reliability, validating the machine’s capability to successfully manage both the large projected area and the required cycle demands.

Explore Industry-Specific Solutions

Our experts can provide detailed information to help you optimize our 350-ton injection molding machine for your specific industry and product needs.

Conclusion

The 350-ton injection molding machine is fundamentally defined by its powerful capability and structural versatility. By providing sufficient clamping force to manage medium-to-large components across diverse industrial sectors, this machine class serves as an essential foundation for efficient, high-volume polymer processing operations globally.

Technological evolution, including the continuous integration of energy-efficient servo-hydraulic systems and sophisticated process control, refines the precision of the molding cycle while optimizing resource utilization. The 350-ton machine remains a stable and adaptable asset for professionals focused on maintaining stringent quality standards and maximizing production consistency.

Ready to Enhance Your Manufacturing Capabilities?

Contact our team for a custom quote on a 350-ton injection molding machine. Let’s build the future together.