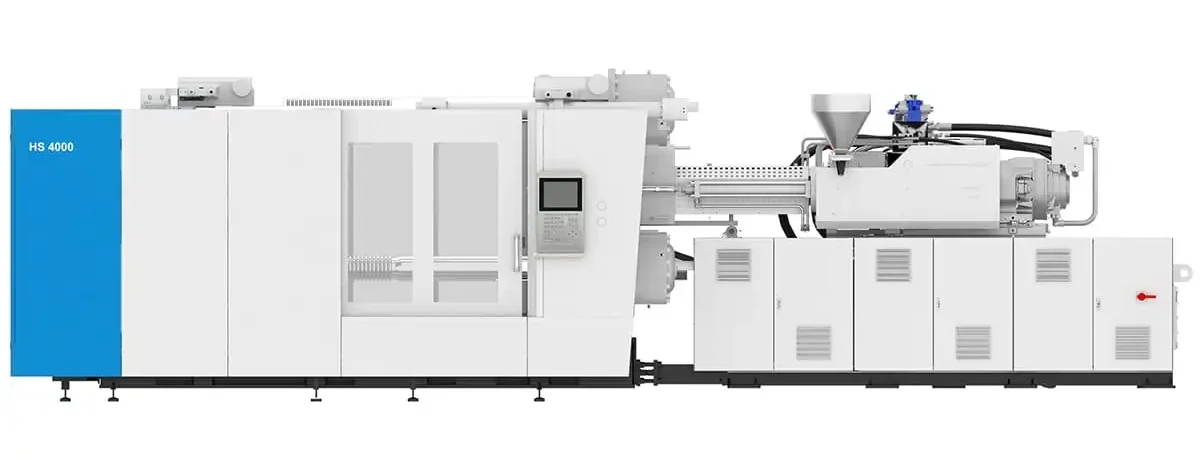

What Is a 4000-Ton Injection Molding Machine?

At its core, the 4000-ton designation is the definitive technical metric. It represents the maximum clamping force the machine can exert (equivalent to 4000 metric tons or 8.8 million pounds). This immense force is essential to counteract the separation force generated by molten plastic as it is injected at high pressure into a large mold cavity.

However, operating at this scale presents two fundamental engineering challenges that define the machine’s modern architecture:

- The Efficiency Challenge: How do you generate and sustain 4000 tons of force—often for long cooling cycles (60-300+ seconds)—without incurring massive, continuous energy costs?

- The Footprint Challenge: How do you accommodate the massive molds required for large parts (like car bumpers or pallets) while keeping the machine’s physical footprint manageable on the factory floor?

The modern 4000-ton machine is an advanced solution to both problems.

To solve the efficiency challenge, these machines have evolved from traditional, fixed-pump hydraulics to Servo-Hydraulic (Hybrid) Systems. These systems combine the immense power density of hydraulics with the precision and on-demand energy savings of electric servo motors.

To solve the footprint challenge, the industry has shifted from bulky, traditional three-platen (toggle) designs to a more compact Two-Platen Architecture. This design eliminates the massive toggle linkage, dramatically reducing the machine’s length while simultaneously offering a much longer opening stroke and superior support for heavy molds.

Therefore, a modern 4000-ton IMM is best defined as a servo-hydraulic, two-platen press—an architecture specifically engineered to deliver extreme tonnage with maximum efficiency and an optimized footprint.

Need Expert Guidance?

Our team of injection molding specialists can help you determine if a 4000-ton machine is right for your manufacturing needs.

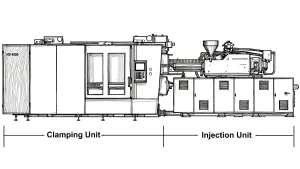

Key Components of a 4000-Ton Injection Molding Machine

A detailed understanding of the mechanical architecture within these high-tonnage systems is essential for appreciating their operational capacity. Each primary component is rigorously engineered to ensure structural integrity, thermal stability, and long-term reliability under extreme loading conditions.

Injection Unit

This unit is rigorously engineered for massive shot sizes and consistent melt delivery under extreme pressure.

- Plasticizing Capacity: Features a robust reciprocating screw (typically 150-250mm) with an optimized L/D ratio for maximizing material throughput and homogeneity across large volumes.

- Thermal Control: A high density of independent heating zones (8-12+) ensures precise, consistent melt temperature. This is critical for polymer stability during the extended cycle times required for large components.

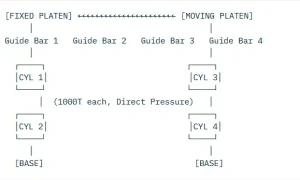

Clamping Unit

The structural foundation is a two-platen system (one fixed, one moving platen) that must withstand 4000 tons of pressure over millions of cycles. This design eliminates the traditional toggle mechanism found in smaller machines, offering significant advantages.

- Platen Rigidity: Massive, precision-machined steel platens are essential to minimize deflection and guarantee part consistency across the critical Projected Area.

- Mold Capacity (Stroke & Daylight): The two-platen design provides exceptionally generous Daylight (like the 4460mm specification) and a long opening Stroke (3460mm). This is crucial for demolding large, deep-draw parts and accommodating complex robotic systems—a key advantage over three-platen designs.

- Tie Bar Strength and Locking: Force is generated by large hydraulic cylinders and mechanically locked, often via a split-nut or locking-pin system on the high-strength tie bars, ensuring reliable management of the 4000 ton force during injection and cooling.

Servo-Hydraulic and Control Systems

Modern 4000-ton machines are dominated by Servo-Hydraulic Systems. This architecture replaces inefficient, fixed-speed pumps with high-precision servo motors directly coupled to hydraulic pumps.

- Power and Precision: This system combines the immense power density of hydraulics (essential for 4000-ton clamping) with the energy efficiency and precision of electric servo drives (used for injection, plasticizing, and pump control).

- Efficiency: The servo motor only rotates when power is needed (e.g., during injection, charging, or clamp movement), drastically reducing energy consumption during the long cooling and holding phases compared to traditional fixed-pump hydraulics.

- Control: Advanced Closed-Loop Control ensures high repeatability by automatically adjusting critical profiles like injection speed and holding pressure, guaranteeing cycle-to-cycle consistency for large parts.

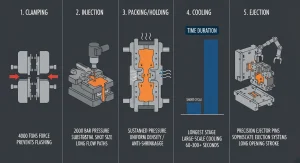

How a 4000-Ton Injection Molding Machine Works

While the fundamental sequence remains consistent across all IMM tonnage classes, the operational scale of a 4000-ton machine introduces unique technical demands. Understanding this process, and the specific engineering required at this size, is crucial for maintaining part quality and optimizing production.

- Clamping: 4000 tons of force is applied, essential to resist the immense separation pressure during injection and prevent flashing across the large mold area.

- Injection: The unit delivers a substantial shot size. Pressures often exceed 2,000 bar, driving material across the long flow paths of large components.

- Packing/Holding: Sustained pressure is maintained to offset volumetric shrinkage in thick-walled parts, ensuring uniform density and dimensional stability.

- Cooling: This is the longest stage. Effective, large-scale cooling circuits are critical due to the sheer volume and mass of the molten polymer.

- Ejection: Requires precision ejector pins and sophisticated robotic systems for safe and efficient handling of heavy, large-format parts, leveraging the machine’s long opening stroke.

Note on Cycle Time: Operational cycles typically range from 60 to over 300 seconds, primarily driven by the extended cooling and packing phases required for large polymer mass and complex geometry.

Tonnage Explained: Focusing on 4000-Ton Capacity

The 4000-ton rating defines the machine’s maximum clamping force (8 million pounds), which is the force required to keep the mold closed against the high internal pressures of injection. This force directly determines the maximum size and complexity of the parts you can mold.

Why 4000 Tons is Essential

Required clamping tonnage is calculated to counteract the total force exerted by the molten plastic across the mold’s Projected Area (Aₚ).

- Projected Area Aₚ: The surface area perpendicular to the clamping direction. Larger parts demand higher tonnage.

- Cavity Pressure Pc: Dependent on material viscosity, wall thickness, and flow length. High-viscosity or thick-walled parts require greater force.

The industry guideline for required force is typically 2 to 8 tons per square inch (ton/in². Therefore, a 4000-ton machine is optimally positioned to manage parts with 500 to 2,000 square inches of projected area, handling the rigorous demands of large industrial components and automotive panels.

The following illustrates where 4000-ton capacity is critical in the large-part market:

| Component Example | Typical Projected Area (in²) | Required Tonnage Range (Tons) | Suitable IMM Class |

| Automotive Instrument Panel | 300-600 | 1,200-3,600 | 2,000-4,500 ton |

| Large Pallets / Industrial Bins | 700-1,200 | 2,800-6,000 | 3,000-7,000 ton |

| Utility Vehicle Body Panel | 500-900 | 2,000-4,500 | 3,000-5,500 ton |

A 4000-ton machine serves the core of the heavy-duty, large-format injection molding market.

Need Help Calculating Required Tonnage?

Our team can analyze your part design and determine the optimal machine specifications for your application.

Main Specifications of the 4000-Ton Injection Molding Machine

These massive machines come with impressive specifications that enable their extraordinary capabilities(Note: The following data is for a representative two-platen servo-hydraulic model, HS4000, for illustrative purposes).:

| Clamping Unit | Unit | HS4000 | ||||||||

| Clamping Force | kN | 40000 | ||||||||

| Mold Opening Stroke | mm | 3460/2260 | ||||||||

| Min. Mold Height | mm | 1000 | ||||||||

| Max. Mold Height | mm | 2200 | ||||||||

| Max. Daylight | mm | 4460 | ||||||||

| Tie Bar Space (H×V) | mm | 2400×2000 | ||||||||

| Ejection Stroke | mm | 550 | ||||||||

| Ejection Force | kN | 580 | ||||||||

| Max.Mould Weight | t | 86 | ||||||||

| Injection Unit | Unit | IU61000 | IU100000 | IU140000 | ||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 180 | 200 | 220 | 220 | 240 | 260 | 240 | 260 | 280 |

| Screw L/D Ratio | L/D | 24.5 | 22 | 20 | 26 | 24 | 22 | 24 | 22 | 20.6 |

| Theoretical Shot Volume | cm³ | 30536 | 37689 | 46616 | 50588 | 60168 | 70614 | 67858 | 79639 | 92363 |

| Shot Weight (PS) | g | 27788 | 34306 | 41510 | 46007 | 54753 | 64258 | 61751 | 72472 | 84050 |

| Injection Rate (PS) | g/s | 1829 | 2289 | 2733 | 2283 | 2717 | 3189 | 2676 | 3140 | 3642 |

| Injection Pressure | MPa | 200 | 162 | 134 | 198 | 167 | 143 | 197 | 168 | 145 |

| Plasticizing Capacity (PS) | g/s | 302 | 374 | 452 | 486 | 578 | 678 | 610 | 716 | 830 |

| Screw Rotation Speed | rpm | 68 | 60 | 58 | ||||||

| General Data | Unit | IU61000 | IU100000 | IU140000 | ||||||

| Heating Capacity | kW | 208 | 220 | 270 | ||||||

| Motor Power | kW | 271+7.5 | 335+11 | 392+11 | ||||||

| Oil tank capacity | L | 3000 | 3850 | 4500 | ||||||

| Theoretical Weight | t | 220 | 225 | 230 | ||||||

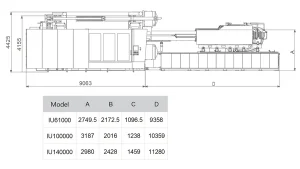

| Machine Dim. (L×W×H) | m | 17.8×5.2×4.5 | 18.9×5.2×4.5 | 13.9×5.2×4.5 | ||||||

Main Features and Benefits

The technological capabilities of a 4000-ton injection molding machine translate directly into significant engineering and operational value for the manufacturer. These machines are not merely scaled-up equipment; they represent a fundamental shift in large-part production economics.

A. Engineering and Structural Superiority

- Monolithic Production: Molding massive components in a single shot eliminates secondary joining steps, drastically reducing tolerance stack-up and potential failure points.

- Structural Integrity: Eliminating weld lines and mechanical joints ensures optimized material continuity, resulting in stronger, lighter, and more durable products.

- Precision Control: Advanced closed-loop systems guarantee tight dimensional tolerances (e.g., ± 0.1 mm range) across very large part surfaces.

B. Operational and Economic Efficiency

- TCO Reduction: Modern servo-hydraulic technology dynamically matches power consumption to operational demand, significantly reducing the energy footprint.

- Automation Synergy: The machine design supports seamless integration with specialized robotic systems for safe, rapid part handling and quality inspection, maximizing throughput.

- Logistics Simplification: Producing a single, complex part streamlines supply chain management, minimizes inventory holdings, and improves material yield.

Differences Between Small and Large Injection Molding Machines

Understanding the distinction between a low-tonnage machine (e.g.,30-ton) and a high-tonnage machine (4000-ton) is essential for appreciating the unique engineering and logistical challenges of large-scale production.

| Characteristic | Low-Tonnage Machine (30-Ton) | High-Tonnage Machine (4000-Ton) | Operational Implication |

|---|---|---|---|

| Footprint (L × W) | 2-3 m × 1 m | 20-30 m × 6-8 m | Logistics: Requires specialized building design and floor space. |

| Nominal Shot Weight | 50-100 g | 50-150 kg | Handling: Demands automated, high-volume material systems. |

| Nominal Power Input | 5-15 kW | 300-600 kW | Infrastructure: Requires substantial electrical capacity. |

| Typical Cycle Time | 10-30 seconds | 60-300 seconds | Thermal: Extended cooling times due to material mass. |

| Installation | Standard factory floor | Reinforced Foundations and Pit | Capital: Requires major civil engineering work. |

Electric vs. Hydraulic Systems

The 4000-ton class is anchored by hydraulic and hybrid technologies, driven by engineering cost and reliability at extreme force levels.

Why Hydraulic Systems Dominate Clamping at 4000 Tons:

- Force Efficiency: Inherently superior and cost-effective for generating and sustaining continuous 4000 tons of clamping force.

- Reliability: Proven robustness and durability in extreme-force, high-stress applications.

- Holding Energy: Maintains lock-up force during cooling with minimal continuous energy input.

Limitations of All-Electric Systems at 4000 Tons

- Prohibitive Cost: Electric components scaled to this force level result in exceptionally high capital expenditure.

- Technical Challenge: Difficulties in reliably generating and dynamically maintaining the extreme forces required.

- Thermal Load: Large electric components require complex and high cooling capacity.

- Market Maturity: Limited successful track record in the ultra-high tonnage segment.

The Hybrid Solution:

The most successful ultra-high-tonnage architecture utilizes servo-hydraulic (hybrid) systems. These drives are integrated with the two-platen clamping unit, combining hydraulic clamping reliability (for sustaining 4000 tons) with the energy-efficient precision of electric servo drives. This provides the optimal balance of immense power and reduced operational cost, making the servo-hydraulic two-platen press the industry standard.

Key Industry Applications for 4000-Ton IMMs

The 4000-ton injection molding machine is a dedicated asset for specific industries where component size, structural integrity, and the cost efficiency of single-piece production are paramount. These applications demand the high clamping force for complex, large-format components.

Automotive

- Complete front/rear bumper fascia

- Integrated dashboard frames (Cockpits)

- Structural underbody shields

- Heavy truck fender flares

Maximum Size & Integration: Required to mold large, complex surfaces (high projected area) and maintain structural continuity, preventing component failure in safety-critical zones.

Civil Infrastructure & Construction

- Large, subterranean manhole structures

- Modular insulated wall panels (SIPs)

- Drainage/piping transition components

Logistics & Material Handling

- High-load capacity pallet systems

- Large industrial bulk containers (IBCs)

- Collapsible storage bins (1,000L+ capacity)

Recreational & Consumer Equipment

- Full pool or spa shells (modular sections)

- Large appliance inner liners (e.g., refrigerator/freezer)

- Kayak/small boat hulls

Agriculture & Utilities

- Large integrated irrigation pump housings

- High-volume feed/water tanks

- Utility meter enclosures and junction boxes.

Industry-Specific Solutions

Our team can help you develop custom applications for your industry using 4000-ton injection molding technology.

Tips for Choosing the Right 4000-Ton Machine

Selecting the appropriate 4000-ton injection molding machine requires careful consideration of several factors:

Accurately Calculate Clamping Force (Tonnage)

- Formula: Clamping Force ≥ Projected Area (cm²) × Material Factor (2-5 tons/cm²)

- Example: The bumper has a projected area of 2 m2 (20,000 cm²), and the PP material is 3 tons/cm² → 6,000 tons is required? Wrong! In reality, only 4000 tons are required (due to pressure sharing in a multi-cavity mold + a 10% safety margin).

- Recommendation:

- Use Moldflow to simulate filling pressure and avoid empirical estimates.

- For thick-walled parts (>8mm), choose a higher tonnage; for thin-walled parts (<3mm), reduce to 3,500 tons.

Matching Shot Volume & Screw

Error Example: Using a 4000-ton machine to shoot a small 10 kg part: Excessive melt residence time, resulting in material degradation.

Platen/Tie-Bar Spacing

| Parameter | Typical Value | Must Verify |

|---|---|---|

| Tie Bar Space (H×V) | Starting from 1800×1600 mm | Mold Width > 2/3 of Mold Length |

| Platen Size | 2500×2200 mm | Supports 4-cavity Pallet Mold |

| Mold Opening Stroke | ≥2000 mm | For Removing Large Products + Robot Arm |

Tips: The mold should occupy ≥70% of the tie rod spacing to prevent template deformation.

Final Recommendations:

- Create a mold drawing first → Calculate tonnage using Moldflow

- Consult three suppliers for free mold trials

- Calculate 5-year TCO, don’t just look at the quote

Conclusion

The 4000-Ton Injection Molding Machine is defined by its ability to execute high-tonnage precision engineering. As this guide has detailed, the modern standard for this class is the servo-hydraulic two-platen architecture, a solution engineered to solve the core challenges of energy efficiency and factory footprint.

This machine serves as a transformative solution, enabling the single-shot production of large, complex components that would otherwise be subject to the cost and structural compromise of multi-part assembly. This capability unlocks significant value in terms of structural integrity, reduced labor inputs, and streamlined supply chain logistics.

While the deployment of a 4000-ton IMM involves major commitments related to infrastructure, utility capacity, and capital expenditure, the strategic returns are substantial across critical sectors like automotive, civil construction, and heavy logistics.

Navigating this critical equipment investment requires a rigorous, data-driven approach. If your organization is considering large-part production, our team of injection molding specialists can provide a detailed technical analysis of your part designs, simulate the molding process, and help determine the optimal machine specifications to ensure your project’s success and long-term profitability.

Ready to Explore 4000-Ton Injection Molding Solutions?

Contact our team of specialists to discuss your specific requirements and discover how our 4000-ton technology can transform your manufacturing capabilities.