The selection process is complicated by the existence of a differentiated technology landscape, comprising hydraulic, all-electric, and hybrid machine architectures. Each configuration provides varying performance profiles regarding energy efficiency, processing speed, and injection precision.

Consequently, a rigorous technical evaluation of key differentiators—including clamping mechanism design, injection control algorithms, and ancillary integration capacity—is mandatory. This technical assessment facilitates an informed capital decision that ensures the machine’s operational specifications are congruous with specific production cycles and long-term performance metrics.

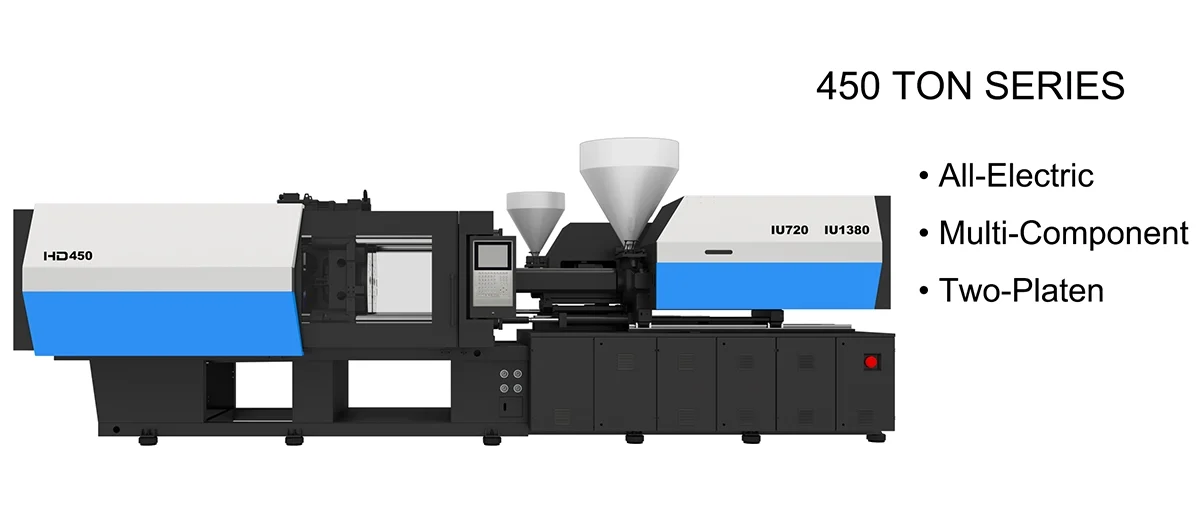

450 Ton Injection Molding Machine: Product Lineup Overview

The 450-ton clamp force capacity is supported by three primary machine architectures, each optimized for distinct operational environments and component characteristics. A high-level technical understanding of these categories is fundamental to equipment specification.

All-Electric 450T

These systems employ servo-driven electric motors for all major machine axes (clamping, injection, and plasticizing).

- Defining Characteristic: Maximum precision, speed repeatability, and quiet operation.

- Target Application Profile: Suitable for high-tolerance medical parts, optical components, and electronics where minimized process variation and exceptional cleanliness are mandatory.

Multi-Component 450T

Multi-Component (Multi-Shot) machines are configured with multiple independent injection units integrated onto a single clamping mechanism.

- Defining Characteristic: Capability to mold products using two or more materials or colors simultaneously in one cycle.

- Target Application Profile: Designed for complex automotive assemblies, seals, and functional consumer products where the integration of materials eliminates secondary processing steps.

Two-Platen 450T

The Two-Platen structure replaces the conventional three-platen system, consisting only of a fixed platen and a moving platen connected by tie-bars.

- Defining Characteristic: Significant reduction in machine length (footprint) without sacrificing tonnage capacity or tie-bar clearance.

- Target Application Profile: Optimal for facilities with limited floor space and the production of large, deep-draw components that necessitate easier access for mold changes and automation integration.

Not Sure Which Machine Type Fits Your Production Needs?

Our injection molding experts can analyze your specific requirements and recommend the optimal machine configuration.

All-Electric 450T Models: Precision and Efficiency

The All-Electric 450-ton architecture distinguishes itself through the complete replacement of hydraulic systems with independent servo motor drives across all operational axes. This fundamental design shift results in highly granular process control and predictable performance.

Key Features and Benefits

- Positional accuracy consistently within ± 0.01mm.

- Power consumption reduced by 30% to 70% via on-demand servo activation.

- Contamination-free operation compliant with strict cleanroom standards.

- Simultaneous axis movements accelerate cycle time optimization.

- Reduced long-term maintenance overhead by eliminating hydraulic systems.

- Acoustic emission levels typically maintained below 65 dB.

- Shot-to-shot consistency maintained below 0.1% for quality control.

- Advanced closed-loop control provides real-time process monitoring.

- Lower internal heat generation minimizes cooling requirements.

- Standardized capability for Industry 4.0 data logging and performance analysis.

Ideal Applications

The inherent capabilities of the All-Electric 450T platform address the stringent requirements of specific quality-mandated sectors:

Medical Components

Essential for contamination-free production and manufacturing devices that demand tight dimensional tolerances.

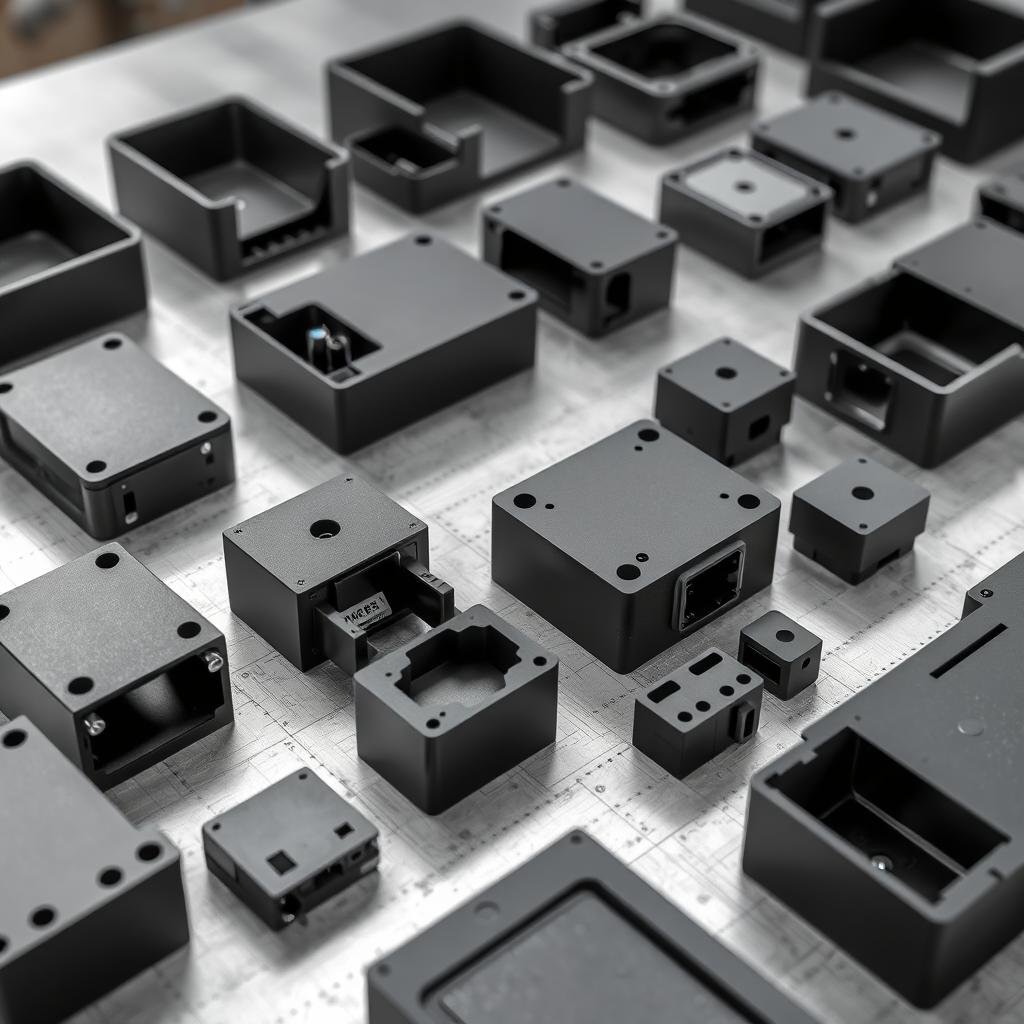

Electronic Housings

Ensures precise geometric control for components requiring strict assembly and fit standards.

Optical Components

Critical for molding high-clarity lenses, light guides, and display components where surface finish, material purity, and micron-level precision are paramount.

Multi-Component 450T Models: Versatility and Integration

The Multi-Component (Multi-Shot) 450-ton platform is engineered for integrating diverse materials or colors within a single molding cycle. This architecture inherently reduces post-molding assembly.

Key Features and Benefits

- Multiple injection units (typically 2-4) for different materials or colors.

- Rotating or indexing mold technology for precise sequential or simultaneous injection.

- Production of complex parts in a single cycle, eliminating assembly steps.

- Material combinations including hard/soft, opaque/transparent, or distinct colors.

- Streamlined production phases through integrated processes.

- Enhanced part functionality through material property combinations.

- Improved aesthetic appeal with multi-color or multi-texture components.

- Advanced control systems for managing complex injection sequences.

- Modular design allowing for future expansion or reconfiguration.

- Specialized nozzle technology preventing material cross-contamination.

Ideal Applications

The capabilities of the Multi-Component 450T platform are essential for sectors demanding complex part integration and material differentiation:

Automotive Components

Production of interior trim, dashboards, and functional modules integrating rigid substrates with soft-touch, ergonomic surfaces or specific color schemes.

Consumer Products

Manufacturing of household appliances, personal care items, and consumer electronics featuring distinctive multi-material grips, visual accents, or integrated sealing elements.

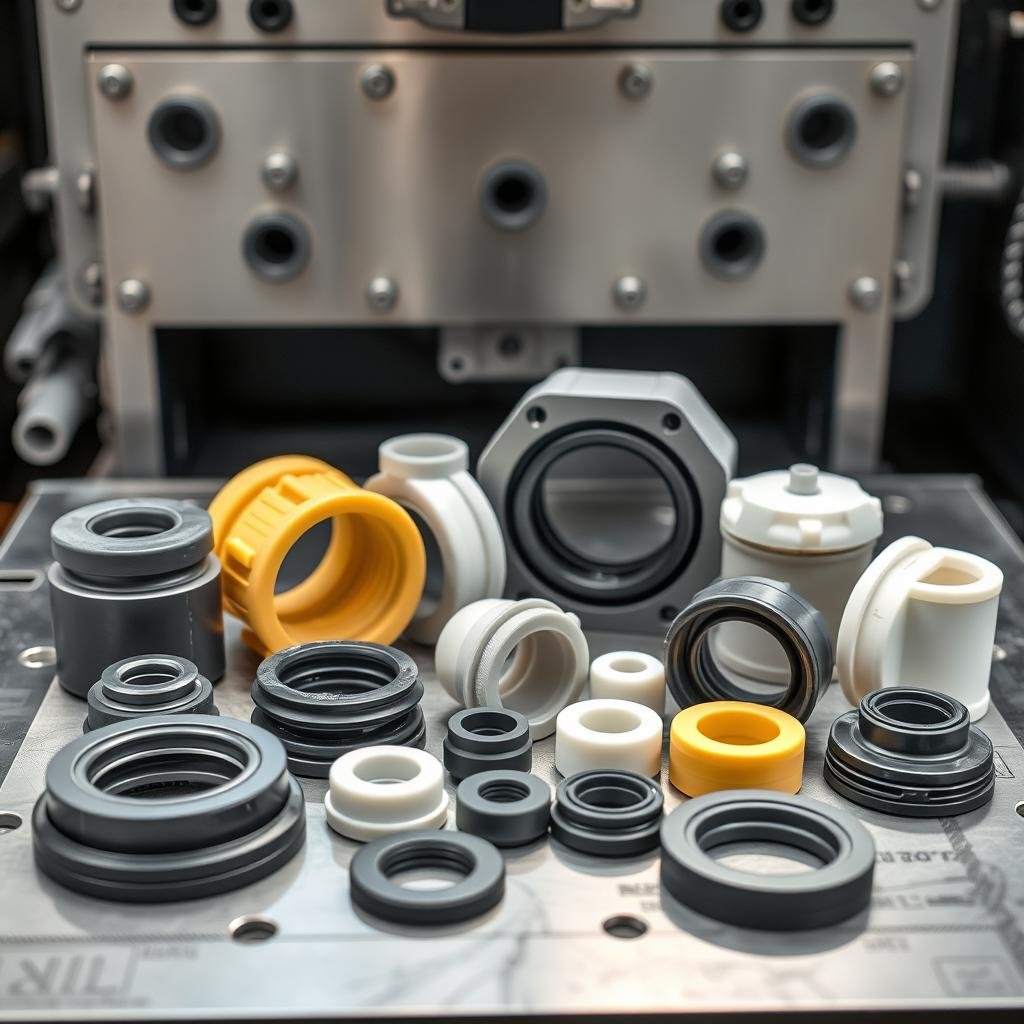

Technical Components

Industrial applications requiring integrated seals, gaskets, or damping elements within a rigid structure, thus bypassing secondary assembly processes and improving part integrity.

Two-Platen 450T Models: Space Efficiency and Power

The Two-Platen 450-ton architecture streamlines the clamping unit by utilizing only a fixed and a moving platen. This design prioritizes compactness and efficient force delivery.

Key Features and Benefits

- Compact design offering up to a 30% smaller footprint compared to conventional three-platen machines.

- Simplified clamping system with fewer mechanical components enhances reliability.

- Optimized hydraulic systems for efficient operational power delivery.

- Even force distribution across the mold platens contributes to consistent part quality.

- Faster dry cycle times resulting from optimized platen movement kinematics.

- Improved mold installation due to enhanced accessibility in the clamping area.

- Reduced oil volume requirements for the hydraulic system, supporting more sustainable operation.

- Hybrid configurations available, combining hydraulic clamping with electric injection units.

- Lower machine height requirements for flexible installation in various facilities.

- Simplified mechanical systems contribute to reduced long-term maintenance needs.

Ideal Applications

The robust design and space efficiency of the Two-Platen 450T platform are particularly suited for demanding industrial applications:

Large Automotive Parts

Production of bumpers, interior panels, and structural components benefiting from consistent clamping force over large areas and optimized factory layouts.

Industrial Containers

Molding of crates, pallets, and large storage bins that require substantial mold dimensions and robust, uniform wall thickness.

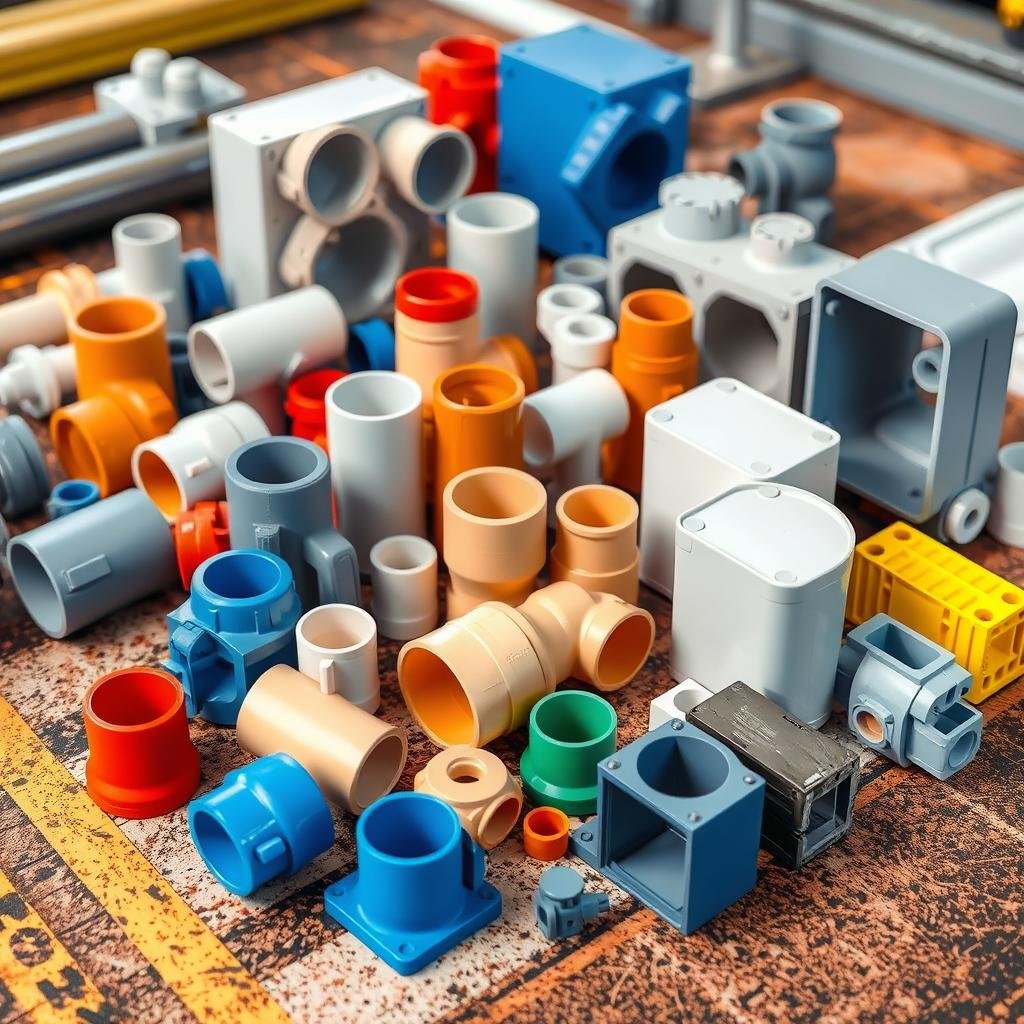

Construction Components

Manufacturing of pipe fittings, electrical enclosures, and structural elements necessitating high clamping forces and efficient use of production floor space.

Need Technical Specifications for Your Project?

For projects requiring precise equipment matching, detailed technical specifications are essential. Our team can provide a comprehensive technical comparison of all 450-ton injection molding machine types, tailored to your specific application requirements.

Technical Comparison: 450 Ton Injection Molding Machine Types

This section provides a direct technical comparison of three distinct 450-ton injection molding machine platforms. The following tables consolidate key specifications, highlighting the structural and performance variations across these architectures.

Overview of 450 Ton Machine Platforms

| Model Identification | Platform Type | Primary Characteristics |

| ES450 | All-Electric Injection Molding | High Precision, Energy Efficiency, Clean Operation |

| HD450 | Multi-Component (Rotary Platen) | Integrated Multi-Material/Color Production, Compactness |

| HS450 | Two-Platen Injection Molding | Space Efficiency, Large Mold Accommodation, Robust Clamping |

1. Clamping Unit Specifications

| Parameter | Unit | ES450 (All-Electric) | HD450 (Multi-Component) | HS450 (Two-Platen) |

| Clamping Force | kN | 4500 | 4500 | 4500 |

| Mold Opening Stroke | mm | 820 | 600 | 1250/750 |

| Min. Mold Height | mm | 350 | 200 | 350 |

| Max. Mold Height | mm | 850 | 750 | 850 |

| Max. Daylight | mm | 1670 | N/A | 1600 |

| Platen Size (H×V) | mm | 1260×1220 | N/A | N/A |

| Tie Bar Space (H×V) | mm | 920×870 | 1130×610 | 810×800 |

| Min. Mould Dimension | mm | 645×580 | N/A | N/A |

| Max. Mould Weight | t | 7 | N/A | 6.5 |

| Ejection Stroke | mm | 220 | 185 | 250 |

| Ejection Force | kN | 108 | 77×2 | 110 |

| No. of Ejector Pin Holes | 17 | N/A | N/A | |

| Diameter of Rotary Platen | mm | N/A | 1300 | N/A |

| Max. Mold Installed Diameter | mm | N/A | 1331 | N/A |

| Bearing Capacity of Rotary Platen | t | N/A | 3.5 | N/A |

| Distance Between Molds Positioning Centers | mm | N/A | 550 | N/A |

2. Injection Unit Specifications (Selected Ranges)

Note: Each model offers multiple injection unit options. The table below presents the range of capabilities for key parameters across the available units for each machine.

| Parameter | Unit | ES450 (IU1400 – IU3100) | HD450 (IU720 – IU1380) | HS450 (IU2450 – IU3700) |

| Screw Diameter | mm | 55 – 80 | 42 – 55 | 65 – 90 |

| Screw L/D Ratio | L/D | 20 – 26.6 | 19 – 24 | 17.8 – 22.9 |

| Theoretical Shot Volume (Max) | cm³ | 2011 | 736 | 2545 |

| Shot Weight (PS, Max) | g | 1918 | 670 | 2316 |

| Injection Pressure (Max) | MPa | 252 | 280 | 242 |

| Injection Rate (PS, Max) | g/s | 350 | 266 | 694 |

| Plasticizing Capacity (PS, Max) | g/s | 757 | 25.5 | 68 |

| Screw Rotation Speed (Max) | rpm | 300 | 210 | 157 |

3. General Machine Data

| Parameter | Unit | ES450 | HD450 | HS450 (IU2450 / IU3700) |

| Heating Capacity (Max) | kW | 48.3 | 19 | 30 / 38 |

| Motor Power (Max) | kW | 143.7 | 33 | 59 / 77 |

| Oil Tank Capacity | L | N/A | 900 | 650 / 850 |

| Theoretical Machine Weight | t | N/A | 20 | 20 / 22 |

| Machine Dimensions (L×W×H) | m | 9.1×2.2×2.3 | 8.0×2.5×2.4 | 6.7×2.3×2.3 / 7.7×2.3×2.3 |

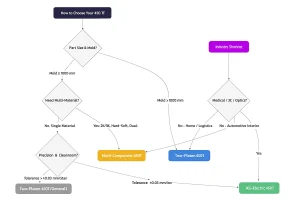

How to Choose 450 Ton Injection Molding Machine

Moving from technical specifications to a finalized equipment specification requires a structured framework that aligns the machine’s inherent capabilities with project demands. The following matrices and profiles serve as a guide for platform evaluation.

Platform Alignment with Core Requirements

This summary connects the defining technical features of each 450-ton platform to critical production objectives.

| Platform Type | Core Application Requirement | Key Technical Rationale |

| Two-Platen 450T | Large Mold Accommodation + Space Efficiency | Mold capacity up to 1250 ×1150 mm, combined with a 30% reduction in machine footprint versus conventional design. |

| Multi-Component 450T | Multi-Material/Color Single-Piece Molding | Integrates production phases by eliminating 2–3 secondary assembly steps, resulting in an average 15% weight reduction potential. |

| All-Electric 450T | High Precision + Cleanroom Compliance | Achieves positional accuracy of ± 0.01 mm, operates at ISO 7 standard, and offers up to 60% energy savings in operation. |

Four-Step Technical Assessment Matrix

This assessment matrix provides a structured approach for technical fitting, prioritizing machine architecture based on four critical project parameters.

| Step | Key Issue for Assessment | Two-Platen | Multi-Component | All-Electric |

| 1. Component Size | Mold Dimension Requirement >1000 mm}? | Optimal Fit | Not Suited | Not Suited |

| 2. Material Complexity | Requirement for Two-Color or Hard/Soft Integration? | Not Suited | Optimal Fit | Upgradeable Option |

| 3. Process Precision | Tolerance Requirement < ± 0.03 mm? | Up to ± 0.05 mm | Up to ± 0.05 mm | Optimal Fit |

| 4. Industry Mandates | Production required for Medical (ISO)/3C/Optical? | Not Suited | Not Suited | Optimal Fit |

Application Scenario Matching and Output Estimation

This table connects typical industry component characteristics (defined by wall thickness) to the optimal platform choice and provides estimated throughput rates.

| Manufacturing Sector | Typical Part Examples | Typical Part Wall Thickness | Optimal Platform | Estimated Daily Output Range |

| Home Furnishings/Logistics | Pallets, Trash Cans | 3-5 mm | Two-Platen | 2K – 3K |

| Automotive Interior | Two-tone Door Panels, Taillights | 1.5-3 mm | Multi-Component | 2K – 4K |

| Medical | Infusion Sets, Syringes | 0.6-1.2 mm | All-Electric | 10K – 15K Shots |

| 3C Electronics | Mobile Phone Frames, Laptop Cases | 0.4-0.8 mm | All-Electric | 8K – 12K Shots |

| Optical | Lens Frames, AR Brackets | 0.3-0.6 mm | All-Electric | 6K – 8K Shots |

Economic Profile: Cost and ROI Drivers (3-Year Horizon)

This comparative profile assesses the financial drivers and total cost of ownership (TCO) across the three platforms over a typical three-year payback period.

| Model | Initial Equipment Capital Cost (Relative) | Electricity Consumption (Relative) | Labor Optimization (Annual Impact) | TCO Driver over 3 Years | Optimized Production Scenario |

| Two-Platen | Lowest Initial Capital Outlay ↓↓ | Medium | Requires 1 Operator per Line (Standard) | Lowest Total Operating Cost | Mass Production of Large, Standard Components |

| Multi-Component | Medium Capital Outlay ↓ | Medium | Potential to eliminate 2–3 assembly personnel | Value derived from process integration | Automotive Interior and Complex Assembly Reduction |

| All-Electric | Highest Initial Capital Outlay ↑↑↑ | Lowest (Up to 60% Reduction) | Requires 1 Operator per Line (Standard) | Highest long-term value in specialized sectors | High-Value Added Sectors: Medical/3C, requiring precision and compliance. |

Conclusion

Determining the optimal 450-ton injection molding platform represents a strategic capital investment that directly secures long-term manufacturing capability. The final specification must carefully align the distinct advantages of each machine type with your specific technical requirements, material processing needs.

Aligning Platform to Context

The suitability of the machine platform is defined entirely by your core manufacturing context:

-

All-Electric Machines: The technical fit for precision applications where dimensional consistency (e.g., ± 0.01 mm) and part quality are paramount.

-

Multi-Component Machines: Deliver significant advantages for complex, integrated parts by eliminating costly secondary assembly steps and reducing total production time.

-

Two-Platen Machines: Offer an excellent balance between high performance and optimized capital expenditure, making them ideal where large molds and space utilization are primary constraints.

We strongly recommend conducting a thorough, multi-factor analysis of your specific production requirements and TCO goals. Engaging with technical specialists and validating your specific molds on different machine types are crucial steps before finalizing the machine specification. This comprehensive, data-driven approach is key to securing a 450-ton solution that maximizes operational success and provides a sustained competitive advantage.

Ready to Find Your Ideal 450 Ton Injection Molding Machine?

Our injection molding experts can provide personalized recommendations based on your specific production requirements and facility constraints.

Frequently Asked Questions About 450 Ton Injection Molding Machines

Q:What are the typical space requirements for a 450 ton injection molding machine?

A:The required machine footprint varies substantially based on the technological platform. Data collected from our representative models (Section 6) indicates the following approximate floor space dimensions (Length x Width):

-

All-Electric (ES450): Approximately 8.2 x 2.1 meters 27 x 7 feet.

-

Multi-Component (HD450): Requires the largest footprint due to the secondary injection units, typically around 9.5 x 2.3 meters 31 x 7.5 feet.

-

Two-Platen (HS450): Offers the most space-efficient design, approximating 7.7 x 1.9 meters 25 x 6.2 feet.

Additionally, adequate surrounding clearance must be allocated for essential functions, including scheduled maintenance access, automated parts handling systems, and safe operator movement.

Q:What is the maximum part size that can be produced on a 450 ton injection molding machine?

A:Maximum component size is governed by the clamping unit’s tie bar spacing and the required projected area of the part. For standard 450-ton platforms, the tie bar spacing typically ranges from 760 x 710 mm to 920 x 870 mm, accommodating molds with maximum dimensions around 750 x 700 mm. This structural limit allows for parts with a projected area of approximately 0.5 square meters, contingent upon the material’s flow characteristics and wall thickness. The final decisive factor is the machine’s available shot capacity, which for a 450-ton machine typically ranges from 1,300 to 2,100 grams (Polystyrene equivalent).

Q:How much energy does a 450 ton injection molding machine consume?

A:Energy consumption is the most significant operational variable among platforms, measured in kilowatt-hours per kilogram of processed material (kWh/kg):

-

All-Electric Machines: Offer superior efficiency, typically consuming 0.3 – 0.4 kWh/kg due to on-demand servo activation.

-

Two-Platen Designs (Hydraulic/Hybrid): Consume moderately more, generally in the range of 0.4 – 0.5 kWh/kg.

-

Multi-Component Machines: Exhibit the highest consumption due to multiple injection barrels and rotary mechanisms, often operating between 0.5 – 0.7 kWh/kg.

For an estimated annual operating schedule of 6,000 hours, processing 500 kg of material per hour, the annual energy consumption can range from 900,000 kWh for all-electric models up to 2,100,000 kWh for less optimized hydraulic systems.

Q:What are the maintenance requirements for different types of 450 ton injection molding machines?

A: Maintenance complexity directly correlates with the machine’s architecture:

-

Hydraulic Systems (Including Two-Platen): Requires routine scheduled maintenance, including hydraulic oil analysis, filter replacement, and system fluid management every 2,000 – 4,000 operating hours.

-

All-Electric Machines: Eliminate hydraulic maintenance but mandate advanced electronic diagnostics, calibration checks, and specialized expertise for the servo motor and drive systems, leading to potentially higher component replacement costs.

-

Multi-Component Machines: Present the highest maintenance complexity due to the integration of multiple independent injection units and the mechanical precision required for rotating or indexing mold mechanisms.

Regardless of the platform, all machines necessitate regular lubrication schedules, tie bar inspection, screw and barrel wear monitoring, and control system software updates.