Every component, from a car’s dashboard to a medical syringe, owes its existence to the precision of an injection molding machine. Yet, the selection of this foundational equipment is one of the most critical and complex decisions a manufacturer faces. An unsuitable machine can lead to compromised part quality, high operating costs, and significant production bottlenecks.

We’ll delve into everything from the crucial consideration of clamping force and shot size to the long-term impact of machine type (hydraulic, electric, or hybrid) and automation capabilities, ensuring you can select a machine that is perfectly aligned with your project requirements and operational goals.

The Fundamentals: How an Injection Molding Machine Works

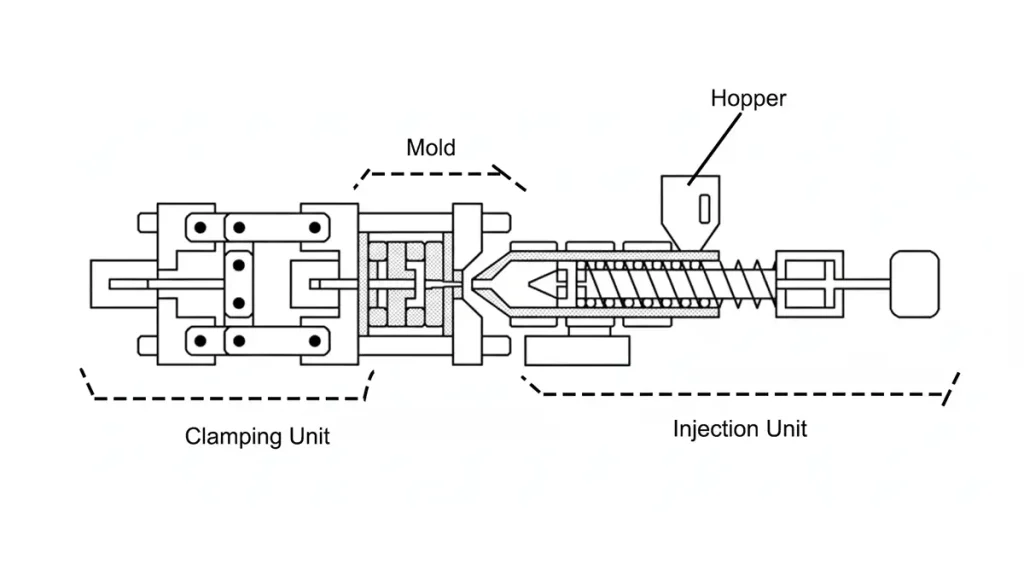

At its core, an injection molding machine operates on the seamless coordination between two primary components: the injection unit and the clamping unit. Understanding their specific roles is fundamental to comprehending the entire process.

The injection unit is the engine of the machine, responsible for preparing and delivering the material. It begins by feeding plastic granules from a hopper into a heated barrel. A rotating screw within this barrel performs three critical functions: it plasticizes the raw material by melting it, homogenizes the molten plastic to ensure uniform consistency, and then injects this precise, pressurized shot into the mold cavity.

Simultaneously, the clamping unit provides the structural integrity required to contain the process. Its primary job is to securely hold the mold closed against the intense pressure of injection. It then maintains this force as the molten plastic cools and solidifies. Once the part is fully formed, the clamping unit opens the mold and ejects the finished part, preparing for the next production cycle.

Together, these units execute a continuous, four-step cycle: the mold closes, material is injected, the part cools, and the mold opens for ejection.

What are the classification of injection molding machines?

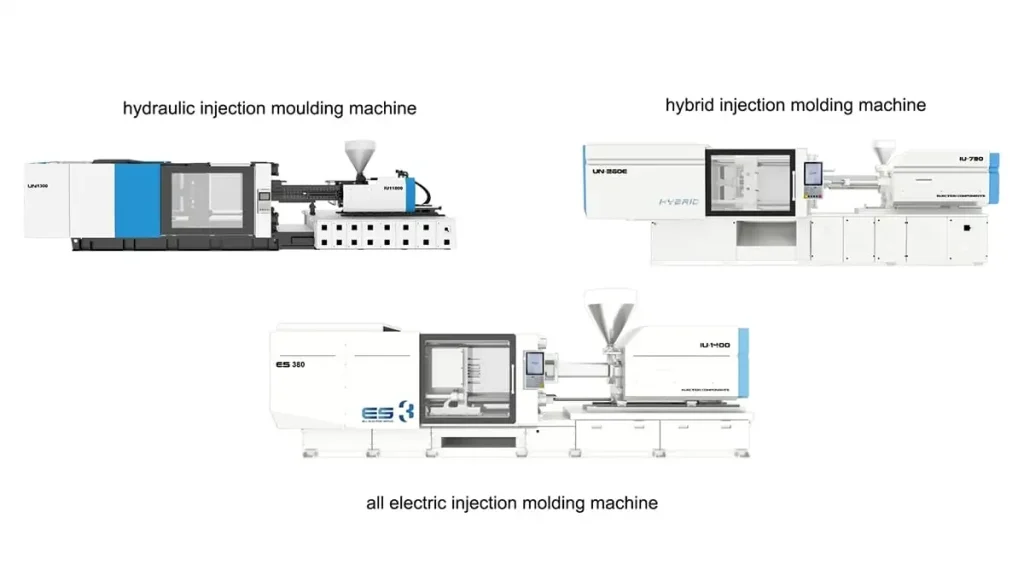

The operational mechanics we’ve just discussed are powered by one of three primary drive systems. Your choice here is the single most impactful decision, directly influencing your machine’s performance, energy costs, and long-term operational efficiency.

Hydraulic Machines: The Industry Workhorse

These machines are the traditional foundation of injection molding. They rely on a hydraulic pump and a constant-speed motor to generate the immense force required for mold clamping and material injection.

Key Advantages:

- Immense Power: They excel at molding large parts and components that require high clamping forces.

- Durability & Robustness: Their sturdy design and relatively simple mechanical components make them incredibly durable and reliable for demanding, high-volume production.

- Lower Initial Investment: Their established technology and mature market typically mean a lower upfront cost, making them an accessible option.

Key Considerations:

- Higher Operating Costs: Their continuous-running pumps lead to significantly higher energy consumption and heat generation.

- Maintenance & Cleanliness: They require more frequent maintenance of the hydraulic system, and the risk of oil leaks can compromise cleanliness in a production environment.

- Lower Precision: They generally offer less precision and repeatability compared to their electric counterparts, which can be a limiting factor for tight-tolerance parts.

Electric Machines: The Modern Precision Powerhouse

Electric machines use individual, computer-controlled servomotors to drive every movement—from the screw to the clamp. This technology offers unparalleled control over the entire molding process.

Key Advantages:

- Unmatched Precision & Repeatability: The precise control of servomotors allows for extremely consistent shot sizes and movements, crucial for high-tolerance medical or electronic components.

- Exceptional Energy Efficiency: They consume up to 70% less energy than hydraulic systems, as motors only draw power when in motion. This results in significant long-term operational savings.

- Cleaner and Quieter Operation: With no hydraulic oil, they are ideal for cleanroom or medical applications and create a much quieter work environment.

Key Considerations:

- Higher Initial Investment: The advanced technology and components mean a substantially higher upfront cost.

- Specialized Maintenance: While less frequent, maintenance may require technicians with specialized electrical and software knowledge.

- Power Limitations: They may be limited in their maximum clamping force compared to large hydraulic machines, restricting their use for very large, high-tonnage parts.

Hybrid Machines: The Best of Both Worlds

Hybrid machines combine the high-force capabilities of hydraulics with the energy efficiency and precision of electric motors. They typically use a servo-driven hydraulic pump that only operates on demand.

Key Advantages:

- Balanced Performance: They offer a compelling blend of speed, precision, and power, making them highly versatile for a wide range of applications.

- Improved Energy Efficiency: They can reduce energy consumption by up to 50% compared to traditional hydraulic machines, without the high initial cost of an all-electric system.

- Cost-Effectiveness: They provide a great middle ground, offering a more affordable entry point to improved performance and efficiency.

Key Considerations:

- Operational Complexity: With both hydraulic and electrical systems, troubleshooting can be more complex.

- Maintenance: While improved, they still require maintenance for both systems, and some risk of oil leakage remains.

| System Type | Best Use Cases | Energy Efficiency | Precision & Repeatability | Initial Cost | Maintenance & Complexity |

| Hydraulic | Large parts, high-tonnage applications | Low | Moderate | Lower | Higher |

| Electric | Precision parts, medical, electronics | High | Highest | Higher | Moderate, Specialized |

| Hybrid | Versatile, medium-sized parts | Medium | High | Medium | Medium-High |

Head-to-Head Comparison: Hydraulic vs. Electric vs. Hybrid

With a grasp of the three main drive systems, the next step is to evaluate their real-world performance against a set of critical metrics. This head-to-head comparison will help you move beyond machine type and focus on the factors that directly impact your ROI and product quality.

Energy Efficiency & Total Cost of Ownership

Energy consumption is one of the most significant long-term costs in injection molding. Electric machines are the undisputed leader in this category, often consuming 30-70% less power than their hydraulic counterparts because motors only draw power when in motion. This translates directly to a lower Total Cost of Ownership (TCO), with many companies recouping their higher initial investment through energy savings alone.

Real-World Example:For instance, an automotive parts manufacturer in Michigan reduced its energy costs by 35% after switching to electric machines, achieving a full return on investment in under 18 months.

Hybrid machines offer a balanced solution, significantly reducing energy use compared to fully hydraulic systems, while hydraulic machines remain the least efficient due to their constant-running pumps.

Precision & Repeatability

For applications with tight tolerances, precision and repeatability are non-negotiable. Electric machines offer superior performance here, thanks to their direct-drive servomotors that provide unmatched control over every movement. This level of precision is critical for industries like medical devices and electronics, where every part must be identical.

Precision Rating:

Hydraulic: 3.3 / 5

Electric: 4.8 / 5

Hybrid: 4.0 / 5

Production Speed & Cycle Time

Cycle time is a key driver of productivity. Electric machines typically boast the fastest cycle times, as their independent servomotors can perform multiple movements simultaneously (e.g., screw recovery while the mold is clamping). This multitasking ability can drastically increase a plant’s output. Hydraulic machines and hybrid machines generally offer comparable, though slightly slower, cycle times depending on the application.

Maintenance & Workplace Environment

Maintenance needs and the working environment are also vital considerations. Hydraulic machines require more frequent and routine maintenance, including regular oil changes, and come with a risk of fluid leaks. They are also significantly louder in operation. In contrast, electric machines are exceptionally clean, quiet, and have fewer moving parts, reducing routine maintenance. While they require fewer service calls, any issues that do arise may demand more specialized technical expertise. Hybrid machines present a mix, with less fluid and noise than hydraulic systems, but still requiring maintenance for both the electrical and hydraulic components.

Footprint & Space Requirements

Finally, a machine’s physical footprint can be a limiting factor. Electric machines often have a more compact design, making them a better choice for facilities with limited floor space. Hydraulic machines, with their bulky hydraulic power units and fluid reservoirs, typically require more space.

How to Choose the Right Injection Molding Machine for Your Business

Having evaluated the core machine types, you’re ready to build your ideal machine profile. This section provides a systematic roadmap to help you translate your project requirements into a precise machine specification and a smart, long-term investment.

Step 1: Define Your Project Needs

Start by answering a few key questions about your product and production goals. This initial step is the foundation of your decision-making process.

- Part Specifications: What are the part’s size, weight, and material? Is the part for a medical, aerospace, or consumer application?

- Production Volume: What is your required annual production volume and the desired cycle time to meet that demand?

- Quality & Tolerance: What are the required part tolerances and surface finish?

Common Pitfall: Overlooking seemingly small details like part complexity or material additives can lead to a machine that is either oversized and inefficient or incapable of handling the application.

Step 2: Calculate Key Machine Specifications

Once your project needs are defined, you can translate them into concrete machine specifications.

- Clamping Force: This is the most critical calculation. Insufficient clamping force will cause the mold to open during injection, leading to flash and scrap parts.

- Calculation: The required clamping force (F) is calculated by multiplying the part’s projected area (A) by the required cavity pressure (P).

- F=A×P

- Understanding Cavity Pressure (P): This value is not a fixed number. It varies significantly based on the material’s viscosity, part wall thickness, flow length, and gate design. Consulting with a materials expert or a reputable machine supplier is essential to determine the correct value for your specific application.

- Shot Size: The machine’s maximum shot size must be sufficient to fill the mold, including runners and sprues. Aim for a machine where your required shot size falls within the 30% to 80% range of the machine’s capacity. This provides optimal plasticizing performance and flexibility for future projects.

- Mold Dimensions: Ensure the mold fits within the machine’s tie bar spacing and has adequate clearance for installation and part ejection.

Step 3: Assess Broader Business & Operational Factors

A machine’s true value extends beyond its technical specifications. Consider these long-term factors that will impact your business.

- Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in energy consumption, maintenance costs, expected service life, and potential resale value to get a realistic view of your total investment.

- Facility & Utilities: Can your facility accommodate the machine’s size, ceiling height, and weight? Do you have the necessary power, water, and air supply?

- Control System & Automation: Evaluate the machine’s control system. Is it intuitive and user-friendly? Does it have the data logging capabilities you need for process control? Is it easily integrated with robotics and other automation?

- Supplier Reputation & Support: Choose a supplier with a proven track record. Look for a team that offers comprehensive installation support, technical training, and reliable, readily available parts and service. A strong partnership is just as valuable as the machine itself.

The Future of Injection Molding Technology

While the previous sections have guided your selection based on today’s needs, the best investment is one that prepares you for tomorrow. The injection molding industry is rapidly evolving, driven by technological advancements that are redefining what’s possible in efficiency, sustainability, and production capabilities.

Smart Manufacturing: Data & Connectivity

The machine of the future is an intelligent, integrated component of a connected factory. Modern machines now come equipped with Industry 4.0 capabilities that enable real-time data collection and analysis. This connectivity allows for:

- Remote monitoring of machine performance and production status.

- Predictive maintenance that identifies potential issues before they cause downtime.

- Seamless integration with factory-wide management systems for streamlined operations.

AI-Driven Process Optimization

Artificial intelligence is taking machine intelligence to the next level. Instead of relying on manual adjustments, AI systems can:

- Automatically optimize machine parameters in real-time to maintain part quality.

- Predict defects before a part is fully molded, significantly reducing scrap and waste.

- Self-correct for subtle environmental or material variations, ensuring consistent output without human intervention.

The Push for Sustainability

Environmental responsibility is no longer just a trend; it’s a core design principle. Machine innovation is being driven by the need for a smaller carbon footprint, with key advancements including:

- Ultra-efficient electric machines that minimize energy consumption.

- Compatibility with new materials, from bioplastics to advanced recycled polymers.

- Precision control that reduces material waste and a machine’s overall environmental impact.

Enhanced User Experience & Automation

As machines become more complex, their interfaces are becoming more intuitive. The future of injection molding is one where operators can rely on:

- Intuitive, tablet-like controls that simplify setup and troubleshooting.

- Integrated automation that seamlessly connects robotics for part removal or downstream processing.

- Smart safety features that improve operator ergonomics and reduce the risk of accidents.

These advancements are not just “nice-to-haves”; they are the defining features that will ensure a manufacturer’s long-term competitiveness. Investing in a machine that is ready for this future is the final, and most crucial, step in your selection process.

Conclusion

We’ve covered the fundamentals, compared the drive systems, and provided a roadmap for your selection process. Now, with the knowledge from this guide, your choice of an injection molding machine becomes a strategic business decision, not just a technical one.

By prioritizing a holistic view—from a machine’s technical specifications and Total Cost of Ownership to its future-proof technology—you’re not just acquiring equipment; you’re investing in a cornerstone of your business. The right machine is the one that perfectly balances your current production needs with the adaptability required for future growth and market demands.

This is where a true partner can make all the difference. As you prepare to translate this knowledge into a confident purchasing decision, our team of experts is ready to provide the hands-on guidance and support you need to ensure your investment is a lasting success.

Need Expert Guidance for Your Injection Molding Machine Selection?

Our team of specialists can help you analyze your specific production requirements and recommend the perfect machine for your application. Don’t risk costly equipment mistakes – get personalized advice from industry experts.