To prevent this, pre-conditioning of raw materials is a critical prerequisite for stable processing. Hopper dryers are engineered to reduce the moisture content of plastic resins to the precise levels specified by the material manufacturer. This guide provides a technical examination of resin drying principles, analyzes the operational mechanics of modern hopper dryers, and details the critical parameters for effective moisture removal. We present a framework for configuring the optimal system based on material type, throughput, and application demands, underscoring that mastery of this technology is essential for achieving consistent part quality and operational profitability.

Why Proper Drying is Non-Negotiable

Hygroscopic plastic materials naturally absorb moisture from the air. Without proper drying, this moisture vaporizes during processing, initiating a chain of quality defects that erode both production efficiency and final product integrity.

Consequences of Improper Drying:

- Aesthetic & Dimensional Defects: Surface issues

- splay marks and silver streaks

- internal bubbles and voids

- dimensional instability or warping

- Degradation of Mechanical Properties:

- Weakened properties (e.g., tensile and impact strength

- Increased material brittleness

- Risk of premature component failure during use

- Production & Economic Impact:

- Increased scrap rates

- Increased cost per part

- Loss of efficiency due to longer cycle times and lower output.

Material-Specific Requirements

Moisture sensitivity varies significantly among polymers. High-performance engineering resins such as Nylon (PA), Polycarbonate (PC), PET, and PBT are highly susceptible. For these materials, the residual moisture content must be exceptionally low, typically below by weight, as specified by manufacturers to ensure optimal processing and final part properties.

Even non-hygroscopic polymers like Polypropylene (PP) and Polyethylene (PE), which do not absorb moisture internally, can accumulate surface moisture from condensation. For these resins, preheating is crucial to eliminate surface moisture, preventing cosmetic defects and ensuring process stability.

Understanding Hopper Dryers: Principles and Operation

Hopper dryers operate through a precisely engineered process that integrates temperature control, optimized airflow, and efficient moisture removal. Understanding these core principles allows operators to maximize drying effectiveness while minimizing energy consumption and preventing material degradation.

Core Operating Technologies

The appropriate drying technology is determined by the material’s hygroscopicity.

Standard Hot Air Dryers (Open-Loop Systems)

These systems circulate heated ambient air through the resin. The hot air raises the material temperature, facilitating the evaporation of surface moisture. Hot air dryers are primarily effective for non-hygroscopic polymers (e.g., PP, PE), where the goal is preheating and the elimination of surface condensation.

Dehumidifying Dryer(Desiccant Systems)

Designed for hygroscopic engineering resins (e.g., PC, PA, PET), these dryers utilize a desiccant wheel to establish a closed-loop environment. The desiccant continuously removes moisture, achieving an ultra-low dew point (often below or ). This extremely dry air is essential for removing internal molecular moisture from the material, meeting the mandatory residual moisture levels, typically below by weight.

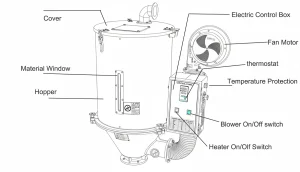

Critical System Components

Process stability depends on the performance and interaction of these three key components:

1.Drying Hopper

This insulated, stainless steel chamber ensures minimal heat loss. Its double-walled construction prevents condensation, and the geometric design promotes Mass Flow, ensuring all material achieves the required residence time.

2.Heating and Control System

Precision-controlled heating elements warm the process air. PID controllers maintain tight temperature tolerances (typically or less), preventing polymer degradation while supplying the energy needed for vaporization.

3.Air Circulation and Distribution

High-efficiency blowers move the process air. Air distribution plates at the hopper’s base are essential for preventing air channeling (preferential paths) and ensuring uniform air contact with of the resin.

Advanced Dryer Controls and Efficiency

Modern hopper dryers utilize integrated controls for sophisticated moisture management, enhancing both product quality and operational efficiency:

- Dew point monitoring – Continuously measures the process air’s dryness, guaranteeing the ultra-low moisture environment required for hygroscopic materials, regardless of external humidity.

- Adaptive Control Algorithms -Automatically adjust heating and airflow based on the material’s actual usage rate, optimizing energy consumption and preventing material overheating.

- Energy Recovery Systems – Capture and reuse residual heat from the desiccant regeneration cycle, significantly reducing the overall system energy demand and the operational cost ().

- Integrated Conveying – Provides seamless, automated integration with material loading and feeding systems, enabling continuous production.

Selection and Configuration Guide

Achieving the quality, efficiency, and cost savings enabled by advanced drying technology depends entirely on correct system configuration. Matching the dryer’s capabilities to your specific material characteristics and production requirements is crucial. The following factors must be evaluated to determine the appropriate drying technology (standard vs. dehumidifying) and overall system capacity.

Primary Selection Criteria

Comparison by Scale: Spot-Drying vs. Central Systems

Dryer specifications vary significantly based on the production scale. Differentiating between a localized, spot-drying setup and a centralized system is key to cost-effective implementation.

Need Help Selecting the Right Hopper Dryer?

Our engineering team can analyze your production requirements and recommend the optimal hopper dryer configuration for your specific application.

Maintaining Peak Performance: Operation and Longevity

The performance of a precisely configured drying system is protected and optimized through diligent maintenance and operational discipline. Following these guidelines ensures consistent drying performance, maximizes energy efficiency, and extends equipment lifespan.

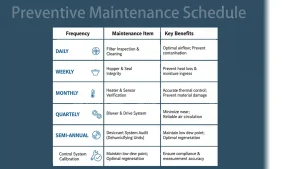

Essential Preventive Maintenance Schedule

System longevity and reliable output depend on a proactive inspection routine:

- Daily: Filter Inspection & Cleaning – Maintain optimal airflow and prevent resin contamination.

- Weekly: Hopper & Seal Integrity – Prevent heat loss and external moisture ingress (reabsorption).

- Monthly: Heater and Sensor Verification – Ensure accurate thermal control.

- Quarterly: Blower & Drive System – Minimize wear, vibration, and maintain system air circulation reliability.

- Semi-Annual: Desiccant System Check – Verify wheel condition and regeneration performance to maintain a low dew point.

- Annual: Control System Calibration – Ensure measurement accuracy for temperature, airflow, and dew point.

Operational Best Practices

Temperature Management

- Use the lowest effective temperature required.

- Allow full warm-up time before processing.

- Verify the actual material temperature.

Material Handling

- Maintain a consistent material level.

- Ensure the full residence time is met.

- Use closed conveying systems to prevent reabsorption.

“The most common cause of inconsistent drying performance is improper maintenance of filters and airflow systems. A simple daily check can prevent costly production issues.”

Troubleshooting Common Issues

- Inconsistent drying: Check for airflow restrictions (filters), material channeling, or insufficient residence time.

- Temperature fluctuations: Inspect heating elements, verify sensor calibration, and check for system air leaks.

- Excessive energy consumption: Examine insulation integrity, optimize regeneration cycles, and verify dryer sizing.

- Material degradation: Confirm correct temperature settings, check residence time, and verify material compatibility.

- Dew Point Spike: Check for leaking seals, saturated desiccant, or a regeneration heater malfunction.

Conclusion & Your Competitive Advantage

The principles and practices detailed in this guide—from core drying mechanics to disciplined maintenance—translate directly into a competitive advantage. Proper material drying is not an expense; it is a strategic investment that immediately impacts your bottom line through superior product quality, minimal scrap, and optimized production efficiency.

Benefits of Optimal Hopper Dryer Implementation

- Zero-Defect Quality and guaranteed mechanical properties.

- Reduced Costs from minimal scrap and efficient material usage.

- Productivity Gains through stable processing and reduced cycle times.

- Stronger Reputation by reducing field failures and warranty claims.

- Lower Energy Costs (kWh/lb) via heat recovery and precise control.

- Extended Asset Life and predictable maintenance costs.

Risks of Inadequate Drying Solutions

- High Rejection Rates and excessive material waste.

- Profit Erosion due to increased production costs.

- Throughput Loss from extended cycles and instability.

- Customer Complaints and potential warranty liabilities.

- High Operating Costs from inefficient, unmonitored systems.

- Unscheduled Downtime and costly emergency repairs.

Mastering precise material drying and implementing the right, data-driven solution secures your sustained success. This strategic move guarantees superior product quality, robust operational efficiency, and verifiable, sustainable manufacturing practices.

Ready to Optimize Your Plastic Processing Operation?

Our team of drying technology experts is ready to help you select, implement, and optimize the perfect hopper dryer solution for your specific materials and production requirements.