The performance of any high-precision Injection Molding Machine (IMM) is directly tied to the consistency of its upstream material supply. A critical, yet frequently underestimated, link in this process is the hopper loader. Data consistently shows that significant efficiency and quality losses can be traced back to an improperly specified or poorly performing loader system.

Your IMM is engineered for continuous, precise operation. Interrupted material supply, or the introduction of contamination or moisture during transfer, simultaneously sacrifices machine uptime and compromises final part quality.

This guide provides a focused, practical analysis of standard, self-contained hopper loader systems. This architecture often represents the most reliable and flexible choice for processors requiring frequent material and color changeovers or autonomous machine setups. Securing material consistency begins here—it is the foundation of a quality molding process.

The Workhorse of the Modern Molding Cell: The Self-Contained Loader

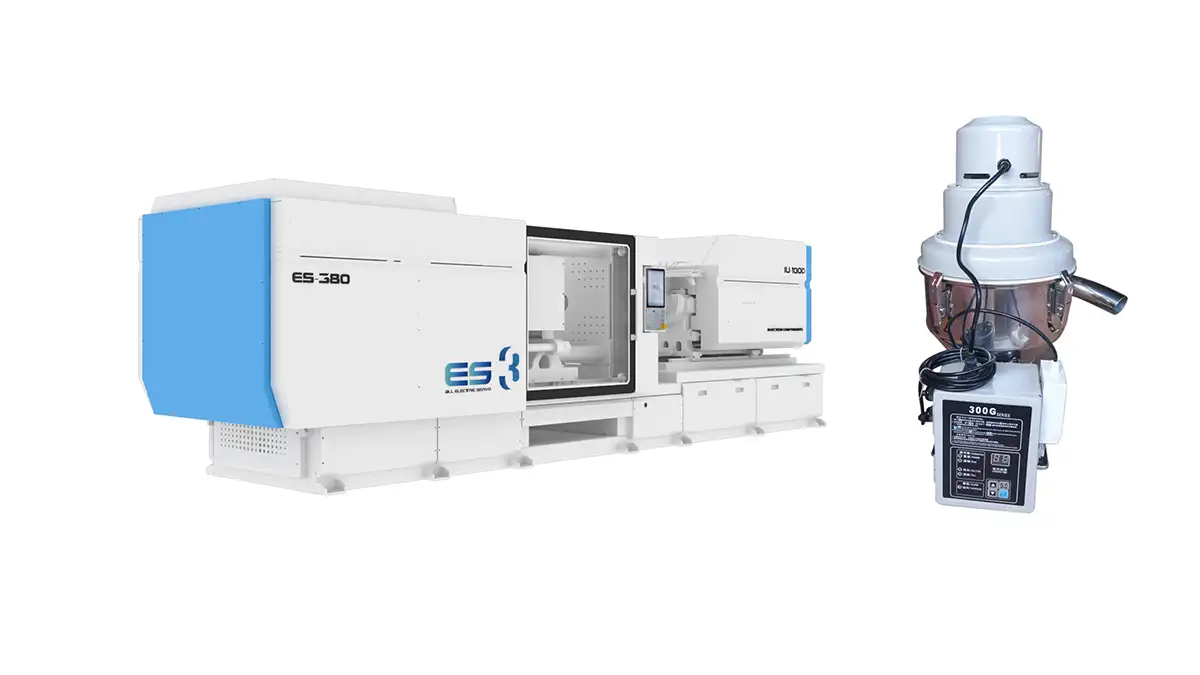

For the modern processor managing diverse jobs, the self-contained (or standalone) hopper loader remains the pragmatic solution. These compact units—integrating the motor, receiver, and controls—are designed to mount directly on your IMM or drying hopper. While Centralized Systems are necessary for massive, high-volume production focused on a single core resin, the self-contained loader provides the agility and simplicity that most facilities depend on.

The ability of this architecture to operate independently is its greatest asset. When you equip each press with a dedicated loader, you fundamentally enhance the performance and risk profile of your core investment:

Key Advantages for Maximizing IMM Efficiency:

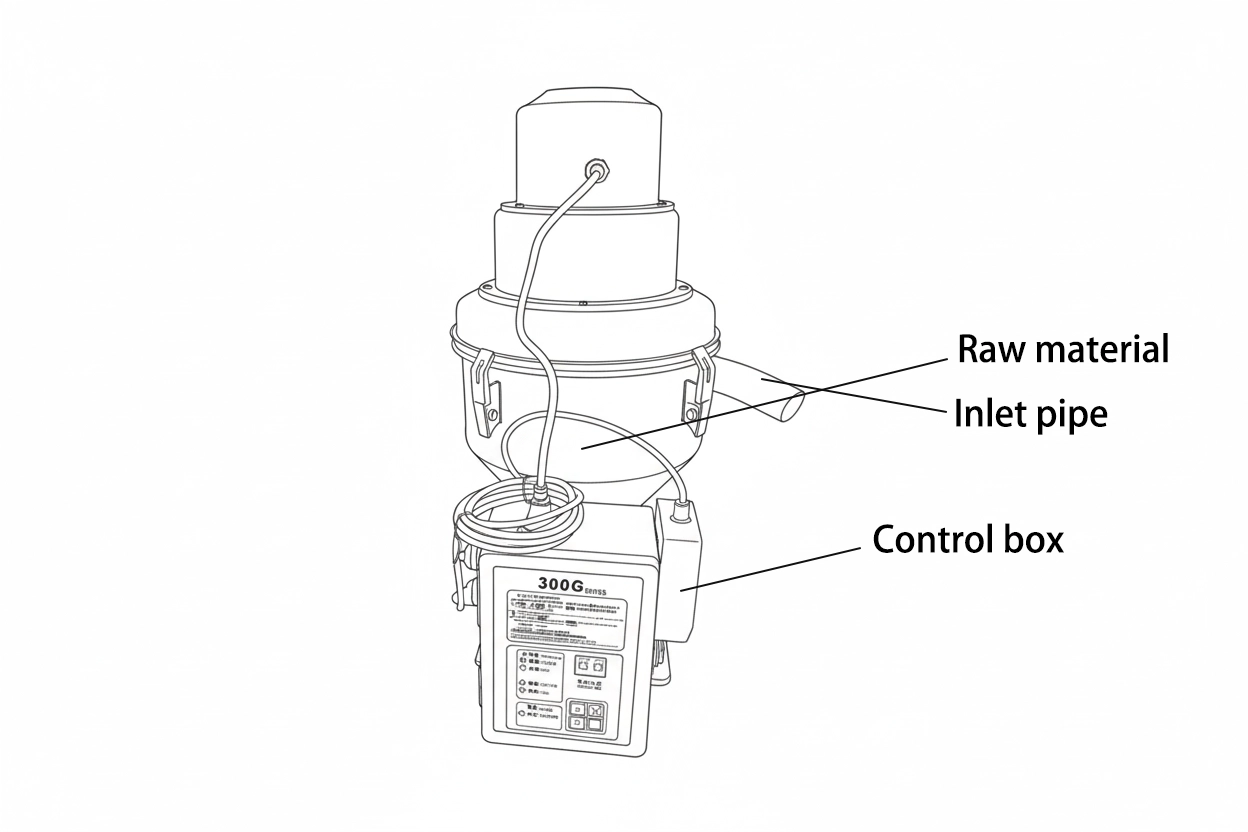

Self-contained hopper loaders integrate the vacuum generator, material receiver, and control system into a single compact unit mounted directly on the processing machine. These systems excel in environments where:

- Maximum Flexibility: Ideal for frequent material or color changeovers, eliminating the risk of cross-contamination inherent in shared systems.

- Simple Installation & Maintenance: As a true plug-and-play solution, it bypasses complex piping networks, keeping maintenance costs and labor focused and manageable.

- Isolated Risk: The failure of one unit will not shut down your entire production floor. This independence secures the overall continuity of your operation.

- Optimized Initial Investment: The lower initial capital cost per unit makes it easy to precisely match a dedicated loader to the specific throughput and material needs of each machine.

Key Technical Specifications for IMM Uptime

Specifying a loader is not about acquiring the biggest motor; it’s about precisely matching its capacity to your machine’s consumption rate, material properties, and conveying distance. This precise sizing is fundamental to eliminating material starvation and maintaining your cycle time.

1. Throughput & Vacuum Power: The Delivery Metrics

These two factors define the loader’s basic capacity and pulling strength. They must be considered together.

- Required Throughput (): The Golden Rule The loader’s minimum capacity must reliably exceed your IMM’s maximum consumption. We recommend a buffer of 20-25% above peak demand to ensure the machine hopper remains full during continuous operation.

- Sizing Note: Self-contained loaders typically handle the – range, ideal for most small-to-medium-sized presses.

- Conveying Distance & Vacuum () The distance and vertical elevation the material must travel directly determines the necessary vacuum pressure (suction). Longer runs, high elevations, or the use of heavy/dense materials require a higher-powered vacuum motor to sustain the required throughput.

2. Material Properties and Flow Control

The physical properties of the resin you process present the greatest technical challenge:

- Free-Flowing Pellets: These materials are the simplest to convey and are compatible with all standard systems.

- Regrind or Flakes: The uneven shapes and varied density of regrind or flakes significantly increase the risk of bridging (material clogging) or line plugging. For high regrind content, ensure the loader unit features a steep cone angle, a well-designed discharge valve, and advanced controls to consistently manage the air-to-material ratio.

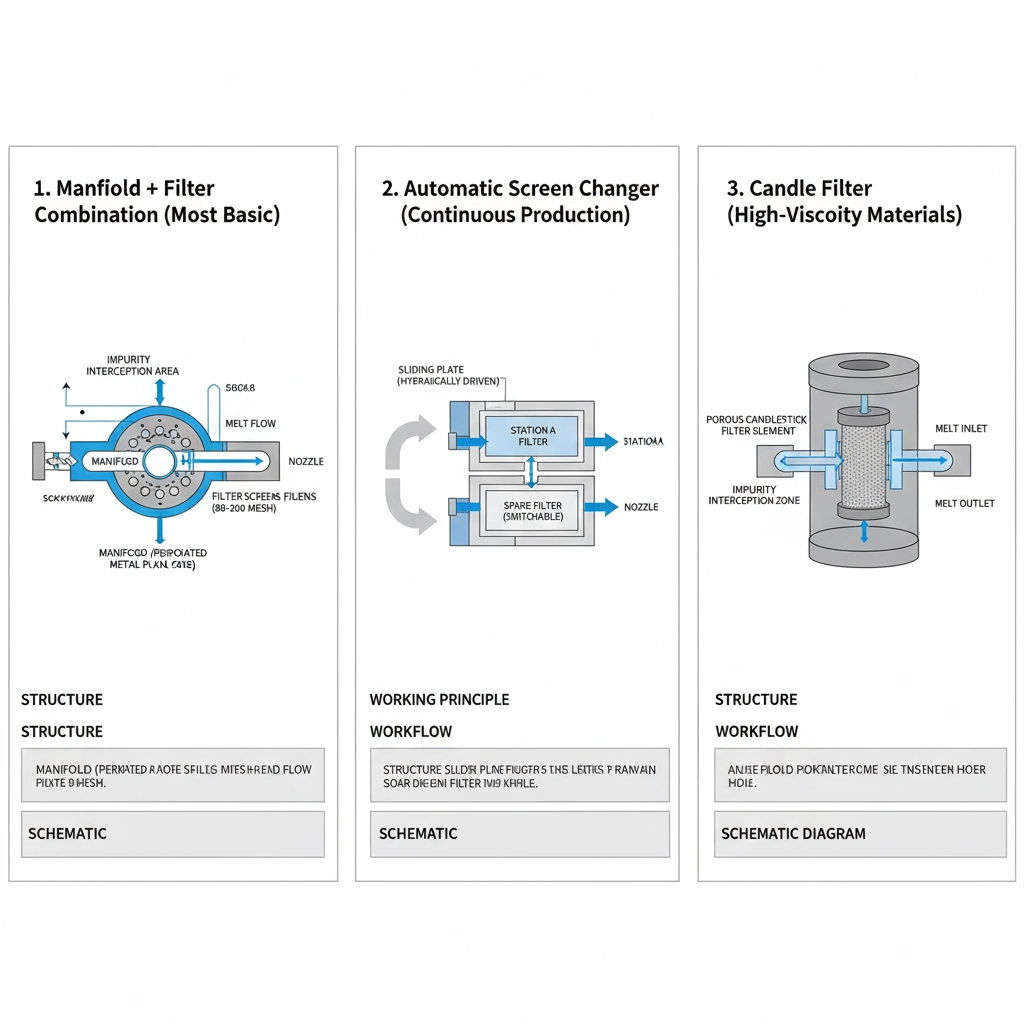

3. Filtration: Protecting Efficiency and Longevity

A robust filtration system is non-negotiable for long-term reliability and low cost of ownership. The filter’s role is dual:

- Protection: It shields the vacuum motor from abrasive dust and fines, preventing premature component wear and failure.

- Performance: A clogged or damaged filter immediately restricts airflow, leading to a dramatic drop in vacuum efficiency and potential material starvation at the machine throat.

Real-World Selection Failure: Case Study

A long-term client in the highly demanding automotive sector contacted us regarding performance issues on one of their newest high-performance IMMs. They were experiencing 3-4 random short shots per shift and initially blamed machine parameters, the mold, or even the material quality.

Diagnosis and Resolution

Our on-site analysis revealed the root cause was a fundamental mismatch: their existing, undersized budget hopper loader simply could not sustain the machine’s aggressive peak consumption rate. This resulted in momentary material starvation at the throat, which in turn produced the inconsistent fill volume that appeared as a short shot.

The Solution was simple and immediate: we replaced the failing unit with a properly sized, standard self-contained loader that was engineered to reliably exceed the IMM’s maximum throughput requirements.

Quantified Results

The results were instantaneous: production interruptions dropped to zero, and part consistency was fully restored. The client calculated that the small, targeted investment in the correct loader saved them over annually in lost production time and scrap costs. This case powerfully illustrates a core principle: the true cost of the loader is measured in the uptime it secures for your core investment.

Conclusion: Making the Right Selection

Your Injection Molding Machine (IMM) is the core manufacturing asset. Ensuring it is consistently fed with clean, dry, and correctly handled material is not merely a requirement—it is the most fundamental factor for sustaining profitability and quality.

By specifying a high-quality, properly sized self-contained hopper loader, you are making a calculated investment based on Total Cost of Ownership (TCO), not just the sticker price. You are securing maximum operational flexibility for material changes and protecting your high-value production uptime. The evidence is clear: the right loader is an essential component that unlocks the full potential and protects the financial return of your primary production asset.

To prevent the common, costly mistakes of undersizing or misapplication, leverage the expertise of a partner who understands the relationship between the machine and the auxiliary equipment.

Ready to optimize your entire molding cell?

Contact our team to discuss how the right auxiliary equipment can maximize the performance of your injection molding machines.