How a Plastic Granulator Works

Effective material recovery is essential to managing a stable and profitable plastics operation. Within this process, the plastic granulator serves as the central piece of equipment. Fundamentally, it is an engineered system for controlled size reduction, designed to consistently transform bulky or irregularly shaped plastic scrap into uniform, high-quality regrind ready for reintroduction into the primary process.

The underlying mechanism relies on the calculated interaction between stationary and moving components, applying shear force rather than crushing the material.

Core Components and Mechanics

The fundamental components of a plastic granulator include:

- Feed Hopper: Safely introduces scrap; guides flow and dampens noise.

- Rotor System: Dynamic element; geometry (e.g., staggered) is key to efficiency and energy.

- Stationary Bed Knives: Fixed blades; sets precise cutting gap for clean, low-friction shear.

- Sizing Screen: Perforated base screen; controls final particle size and uniformity.

- Collection System: Removes finished regrind; often includes dust/air evacuation.

The Granulation Process

Once material enters the chamber, the high-speed rotor (with operational speeds generally ranging from 200–900 RPM) initiates a constant shearing action against the stationary knives. This scissor-like process fractures the plastic into smaller fragments.

The sizing screen dictates when a fragment is complete. Only particles that meet the defined dimensional requirements can pass through the screen openings. Any oversized pieces are naturally retained and recirculated back into the path of the rotor blades until they reach the target size. This recirculation process is key to achieving consistent particle geometry.

Furthermore, managing the heat generated by friction is a critical factor for maintaining material quality. Many industrial granulators incorporate integrated air evacuation systems that actively draw heat and fine dust away, helping to prevent thermal degradation and ensuring the regrind retains its structural and processing integrity.

Particle Geometry and Processing Consistency

The resultant regrind size typically falls between 3 mm and 12 mm, adjusted simply by changing the screen size. The selection of this output size is directly linked to the application. For instance, reclaiming heavy-gauge parts might use a coarser screen for higher throughput, while delicate film scrap requires a finer setting to create a denser, more consistent particle.

Ultimately, the goal of granulation is not just size reduction, but the creation of consistent particle geometry. This uniformity is paramount, as it ensures that the regrind can be reliably mixed and metered into the primary processing equipment, minimizing feed fluctuations and maintaining a stable, high-quality end product.

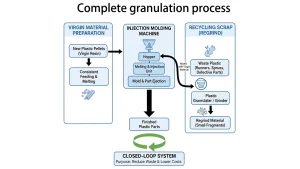

The Primary Application: Creating Value from Injection Molding Scrap

The most immediate and fundamental application for a plastic granulator is within injection molding operations. Here, the granulator fundamentally changes how production byproducts are managed, shifting scrap material from a disposal issue to an on-site, recoverable asset. By enabling a highly effective closed-loop recovery process, manufacturers gain real-time control over their valuable material stream, directly supporting efforts to stabilize production costs.

Common Material Streams from Injection Molding

Granulators are designed to efficiently handle the predictable streams of polymer offcuts generated during the molding cycle. These materials, which represent untapped value, include:

- Runners and Sprues: Material from flow channels; includes cold-runner waste and hot-runner purge.

- Rejected Parts: Components failing quality checks (dimensional/surface faults); a clean source of polymer.

- Purge and Start-up Scrap: Transitional material from warm-up or material/color changeovers.

Economic Benefits of Granulation

Granulating scrap delivers measurable financial gains:

- Material Value Maximization — High-quality regrind can directly replace a portion of virgin resin (the inclusion ratio is specific to the material and application).

- Logistics Efficiency — In-press processing eliminates the complexity, storage needs, and cost of handling and transporting scrap for off-site disposal.

- Inventory Control — Reducing the need for new material purchases enables a leaner raw material inventory and minimizes capital tied up in stock.

- Consistent Material Feed — Ensuring regrind is fresh, dry, and uniform promotes stable metering and feeding for consistent final product quality.

Environmental Impact

Beyond cost savings, it also supports sustainability goals:

- Resource Efficiency — Reprocessing material uses significantly less energy than producing virgin resin, lowering the overall operational footprint.

- Closed-Loop Model — Keeping material in the production cycle minimizes waste volume and supports organizational zero-landfill commitments.

- Verifiable Compliance — A reliable, auditable internal reclaim system is a practical way to meet corporate sustainability mandates and demonstrate environmental responsibility.

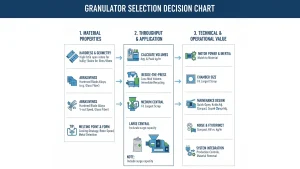

How to Select the Right Granulator for Your Needs

Specifying the correct granulator is less about choosing a machine and more about establishing a strategic fit between your production requirements and the equipment’s engineering capabilities. The most successful choice balances performance and uptime against the machine’s Total Cost of Ownership (TCO) across its lifecycle.

Phase 1: Material Chemistry and Geometry

The fundamental properties of your scrap material must be the primary driver of the granulator’s design. These characteristics directly influence the necessary machine robustness and configuration:

- Hardness and Thickness — Determines required rotor inertia and blade quality.

- Abrasiveness — Requires hardened blade alloys for wear management (e.g., glass fiber).

- Melting Point and Form — Sets cooling strategy and rotor speed to prevent softening/fines.

- Contamination Potential — Requires integrating metal detection or specialized feeding.

Insider Tip: When dealing with bulky, thick-walled parts, look for robust open rotors with high inertia. For films or fibers, specialized V-cut or staggered-blade geometries are preferred for their ability to deliver a clean cut and improve material feed.

Phase 2: Throughput Requirements

Accurately calculating your average and peak material volume is essential for determining the right machine class and system positioning (at-the-press vs. central).

Phase 3: Technical Specifications and Operational Value

Since granulator specifications are not standardized—they vary significantly based on manufacturer design and target application—relying on generic figures is misleading. The final selection should be based on matching your needs to key operational and engineering features:

- Motor Power & Inertia: Must match material thickness and density. High rotor inertia is essential for processing thick, dense parts efficiently and preventing stalling.

- Chamber Size: The cutting chamber and throat opening must comfortably accept your largest scrap (e.g., bulky purges) to eliminate time-consuming manual pre-cutting.

- Maintenance Design: Look for features like quick-open chambers and external knife adjustments. Minimal downtime for cleaning and blade rotation directly boosts production efficiency.

- Noise & Footprint: Compact, sound-dampened designs are critical when integrating units beside the press to ensure a comfortable working environment.

- Energy Efficiency: Compare consumption against verified output to accurately gauge the machine’s long-term operating cost.

- System Integration: Assess the ease with which the unit’s controls and material removal system can be linked for seamless, automated handling within your existing production line.

Final determination of the correct specification requires material testing and verification against the supplier’s performance curves for your specific polymer. This ensures the theoretical output matches your actual operational reality.

Find Your Ideal Granulator Configuration

Our selection guide matches your material, throughput, and production needs to recommended models and replacement parts.

A Real-World Example: Case Study

Automotive Parts Manufacturer Reduces Waste by 42%

Challenge

A large automotive parts manufacturer in the Midwest faced significant cost pressure from high-volume production waste. Their injection molding lines generated approximately of plastic scrap weekly, composed primarily of high-volume Polypropylene (PP) runners and purge, alongside rejected Polyamide (PA) components. The dual problem was clear: substantial disposal fees combined with the continuous loss of valuable, unrecovered material. This directly undermined both profit margins and the company’s strict sustainability mandates.

Solution

The company implemented a system-level granulation strategy based on material flow and facility layout. The key lies in precise equipment matching and integration:

- At-the-Press Efficiency: Three dedicated beside-the-press granulators were deployed immediately next to the molding machines to process the high-volume PP runners and sprues, ensuring the regrind was fresh and dry for immediate reuse.

- Centralized Processing: One larger, central granulator was installed to handle the bulkier, higher-value PA rejected parts, which required more specialized handling and quality control.

- Logistics Automation: All regrind was centralized using automated conveyors and vacuum transfer systems, drastically reducing manual labor and potential contamination risks.

Results

Measured over a robust six-month period, the integrated system provided immediate and sustained value, highlighting the clear link between smart machinery deployment and financial return:

The success of this closed-loop system relies on two core principles: equipment matching for optimal efficiency and strict quality control procedures to ensure material integrity. Specifically, large quantities of PP runners can be safely reused at high mix ratios, while PA scrap, critical for high-performance parts, is conservatively blended and closely monitored to ensure consistent quality throughout the reintroduction process.

Conclusion

The granulator is a foundational technology that helps manufacturers turn production scrap into a recoverable material stream. Properly specified systems immediately reduce material costs and waste disposal fees, delivering measurable economic results while simultaneously fortifying corporate sustainability metrics.

The key to unlocking this value, as demonstrated throughout this analysis, lies in treating selection as an engineering matching exercise. It demands a detailed evaluation of your material characteristics and required throughput against a machine’s unique design and capabilities. When the equipment is correctly matched and integrated with stringent quality-control protocols, the result is consistent, reliable regrind that can be reintroduced into production without risk to final part performance.

The need to maximize material utilization and minimize industrial footprint has fundamentally shifted, making on-site recycling less of a preference and more of a competitive necessity. Deploying the right granulator solution today represents a strategic decision that produces both near-term cost reductions and long-term material security essential for a stable production line. We encourage manufacturers to approach this not as a simple equipment purchase, but as a long-term investment that requires the guidance of an experienced partner to ensure optimal configuration and integration.

Expert Consultation for Your Specific Needs

Our technical specialists review your material streams and production needs to recommend an optimized granulator configuration, necessary equipment, and acceptable regrind blend strategies.

Frequently Asked Questions (FAQs)

What is a plastic granulator and how is it used?

A plastic granulator is a size-reduction machine that converts production scrap into uniform, reusable granules (typically , controlled by the screen). It uses rotating and fixed blades to achieve a clean cut. The machine is essential for reclaiming runners, rejects, and purge materials, turning waste into an immediate resource for production.

What types of granulators are available?

Models are matched to material form and throughput:

- Beside-the-Press: Compact, low-speed systems for continuous processing of runners and sprues at the machine.

- Central: Larger units for centralized handling of multiple scrap streams or bulky rejected parts.

- Film/Sheet: Configured with specialized rotor geometries to process thin, flexible scrap, minimizing fines.

- Heavy-Duty: Robust machines with high inertia for thick, tough materials like purges, pipes, and automotive components.

- Specialized: Includes soundproof models or wet granulators for specific temperature or washing requirements.

How does granulating affect final product quality?

Quality relies on uniform particle size, clean cuts, and contamination control. Correct screen selection and consistent blade maintenance minimize the creation of fine dust, which can degrade material properties. Material testing and controlled blending verify that the regrind maintains material integrity.

What should I consider when selecting a granulator?

Assess material characteristics (hardness, abrasiveness), precise throughput needs, the physical geometry of the parts, footprint and noise constraints, energy efficiency, maintenance access, and how seamlessly the granulator will integrate with your existing material handling equipment.