The effectiveness of this homogenization process is fundamental; it is the primary defense against cosmetic defects, such as color streaks, and critical structural flaws, such as inconsistent mechanical properties. By enabling precise control over material formulations, these systems empower manufacturers to not only achieve exacting quality standards but also to maintain part-to-part consistency across high-volume production runs.

This guide provides a comprehensive overview of the material preparation systems available for injection molding. We will examine their operational principles, common industry applications, and the key factors that inform equipment specification for your unique production environment.

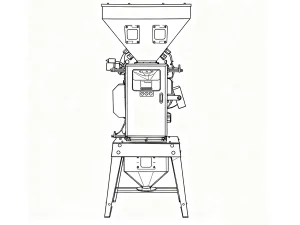

Product Overview and Working Principles

Achieving the blend consistency promised requires a deep understanding of the equipment’s architecture and operational science. The internal design of blenders and mixers translates raw material ratios into flawless, repeatable parts.

Core Components

- Mixing Chamber: The environment where components converge. Its geometry (e.g., paddle vs. screw) is the primary determinant of final material homogeneity and the mixing mechanism employed.

- Mechanical Agitators (Blades/Screws): These elements provide the kinetic energy. Configurations range from simple tumble drums (purely distributive) to twin-screw arrangements that introduce necessary shear for tight color dispersion.

- Motor and Drive System: Provides the precise, repeatable speed and torque essential for consistent material flow and mixing intensity, particularly in highly controlled gravimetric systems.

- Metering Systems (The Crucial Determinant): These are the heart of accuracy, defining the blender’s capability:

- Volumetric Metering: Measures components by volume. Cost-effective, but susceptible to errors from material bulk density shifts or vibrations.

- Gravimetric Metering: Measures components by weight, typically utilizing the loss-in-weight principle. This method is self-calibrating and automatically compensates for density variations, providing the high precision () necessary for critical additives.

Batch vs. Continuous Processing

The operational methodology defines the timing and consistency of material preparation.

| Feature | Batch Blending | Continuous Blending (Dosing) |

|---|---|---|

| Operation Method | Prepares a fixed quantity of material off-line. | Processes material in an uninterrupted, on-the-fly flow at the machine throat. |

| Ideal Application | Low-volume jobs and frequent material changeovers. | High-volume, long-run production demanding Just-In-Time (JIT) material supply. |

| Control Method | Weight-based metering per cycle/batch. | Rate-based metering over time, constantly monitored by gravimetric systems. |

| Flexibility | Easier, faster material changeovers and cleaning. | Maximum consistency over extended periods, minimizing segregation risks. |

Mixing Mechanisms: Shear vs. Distributive

Regardless of whether blending is batch or continuous, the quality is governed by the two fundamental mechanisms materials undergo:

Shear Mixing (Dispersive):

Involves intense mechanical stress to actively break down pigment agglomerates and force dispersion at a molecular level. While essential for color, it generates higher heat (thermal load), requiring careful control.

Distributive Mixing:

Focuses purely on the spatial rearrangement of components to achieve uniform distribution (similar to laminar flow). It is preferred for maintaining the integrity of delicate fibers or minimizing thermal degradation.

Standard Classification of Blenders and Mixers

When specifying a blending system, the fundamental choice hinges on the metering principle, which dictates the level of achievable accuracy and directly impacts material cost control. This critical classification divides systems into gravimetric and volumetric types.

Gravimetric vs. Volumetric Systems

This classification is determined by the method used to meter components, directly impacting blend accuracy and material cost control.

Gravimetric Systems

- Principle: Measure component mass using precise load cells, relying on the loss-in-weight principle to continuously monitor and self-calibrate dosage.

- Precision: Provides superior accuracy, often better than to , compensating automatically for variations in material bulk density.

- Use Case: A medical device manufacturer utilizes gravimetric blending to ensure exact, traceable proportions of base resin and biocompatible additives for implantable components, where material consistency is paramount for regulatory compliance.

Volumetric Systems

- Principle: Measure components based on fixed volume (e.g., auger speed over time).

- Precision: Simpler and more cost-effective, but inherently less accurate (typically to ) as they cannot adjust for density fluctuations.

- Use Case: A high-volume packaging manufacturer employs volumetric blending for non-critical containers where slight variations in color concentration are acceptable and optimizing initial equipment investment is the primary objective.

Need Precision Advice on Your Blending Challenge?

Selecting the right system—Gravimetric or Volumetric—is a critical decision for your material costs and product quality.

Application Scenarios and Advantage Analysis

Blenders and mixers serve critical functions across diverse, demanding industries. Their proper integration is a direct pathway to significant gains in product quality, production efficiency, and material cost savings.

Industry Applications

Each industry presents unique material challenges that require tailored blending solutions, where consistency is the primary driver of product integrity and compliance.

Automotive

- Achieving precise color consistency across large surface areas (e.g., dashboard components).

- Reliably incorporating performance additives like reinforcing fibers and flame retardants for structural components.

- Supporting weight-reduction applications utilizing foaming agents.

Packaging

- Precise dosing of FDA-compliant additives and UV stabilizers for food-contact materials.

- Supporting multilayer barrier packaging integrity.

- Facilitating the consistent flow necessary for demanding thin-wall applications.

Medical

- Providing the traceable accuracy necessary for biocompatible blends used in implantable devices.

- Strict control for mixing radiopaque compounds and ultra-pure materials to maintain CFR Part 820 quality standards.

Consumer Electronics

- Integrating specialized materials such as EMI shielding compounds for signal protection.

- Blending thermally conductive materials for heat management.

- Dosing static dissipative materials to protect sensitive components.

Construction

- Ensuring the durability and longevity of materials through consistent dosing of UV stabilizers and weather-resistant compounds.

- Supporting structural integrity by reliably incorporating reinforcing fillers.

Key Advantages

Material and Cost Efficiency

- Additive ROI: Precise gravimetric dosing eliminates the over-use of expensive additives, directly boosting the material Return on Investment (ROI).

- Resource Maximization: Accurate preparation maximizes the controlled incorporation of recycled materials (up to in some cases) and reduces waste/rework, yielding 5% to 15% material savings.

- Inventory Control: The ability to create custom blends on-demand simplifies logistics and drastically reduces the need to stock pre-compounded materials.

Production Efficiency and Quality Control

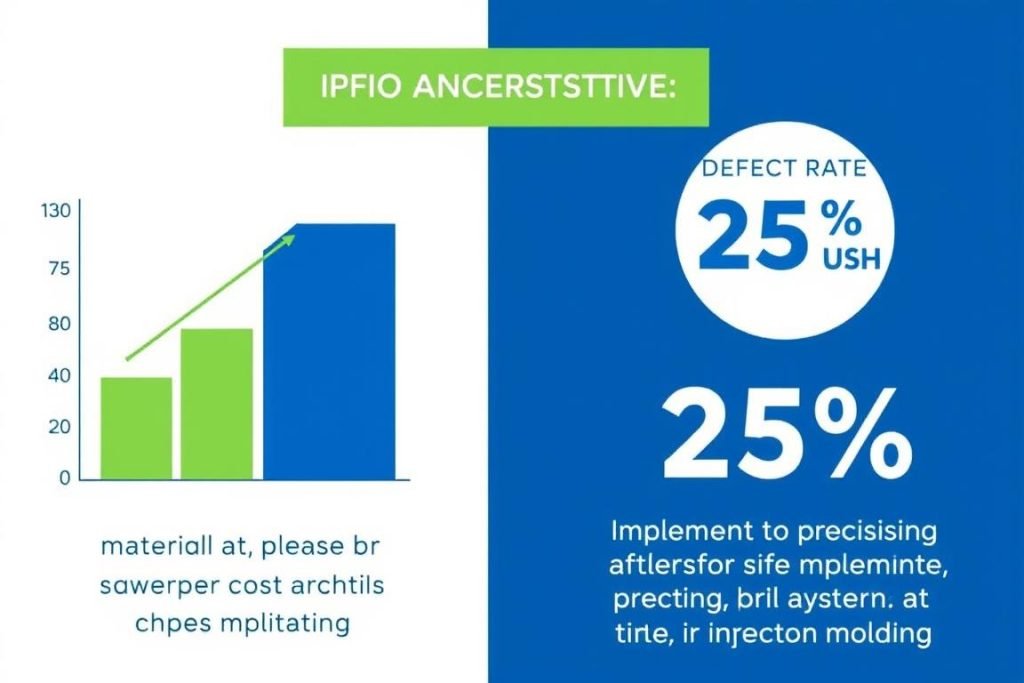

- Quality & Stability: Consistent material feed enhances Melt Flow Stability, minimizing variations and leading to 15% to 25% fewer quality defects.

- Operational Uptime: Accurate dosing reduces lengthy startup tuning time and lowers the incidence of material-related issues (like clumping), ensuring maximum operational uptime.

Procurement Guide, Usage, and Maintenance Recommendations

Determining the optimal blending system is a foundational decision that directly controls your material usage and long-term quality consistency. This section details the necessary criteria for equipment specification and best practices for sustained precision.

Key Procurement Criteria

When evaluating a new blender or mixer, focus on how the system mitigates risk and ensures scalability over the lifecycle of the equipment.

| Criteria | Strategic Importance and Key Takeaways |

|---|---|

| Throughput Capacity | Critical: Must match peak demand with excess capacity to prevent bottlenecks and ensure long-term scalability. |

| Accuracy Requirements | High: Directly controls material consumption and guarantees compliance with critical product tolerance levels (e.g., ). |

| Material Compatibility | Critical: Verifying suitability for specific resins and additive types (powder, fiber) prevents component wear and feed instability. |

| Data & Control System | High: Essential for QA validation and traceability; look for comprehensive data logging and Industry 4.0 connectivity (e.g., OPC UA). |

| Changeover Efficiency | Medium to High: Rapid material exchange and easy internal access minimize downtime and support agile manufacturing. |

| Regulatory Compliance | Varies by Application: Non-negotiable for regulated industries (FDA/CFR ) as it impacts system material contact points. |

Maintenance Best Practices

Scheduled Health Checks: Mitigating Drif

- Daily Integrity Checks: Verify material flow stability, control system alerts, and listen for unusual operating noises.

- Weekly Calibration Verification: Test weighing systems against certified standards and inspect all seals and flexible connections.

- Monthly Performance Review: Review mixing element wear (blades/screws) and check motor and drive system alignment.

- Annual System Audit: Conduct a full mechanical audit, system calibration, and update control software.

Core Accuracy Protocols

- Wear Inspection: Check screw/blade wear every operating hours; prompt replacement is crucial for maintaining shear consistency.

- Purge Protocols: Use material-specific cleaning procedures to eliminate residual contamination (especially high-pigment colorants).

- Weight System Calibration: Systematically verify load cell sensitivity against certified standards to safeguard metering precision.

- Electrical Review: Periodically check all sensor and power connections to prevent intermittent feed rate fluctuations.

Conclusion

Specifying the right blender or mixer system represents a foundational technical decision that directly controls product quality, production throughput, and overall process stability. By understanding the classifications, application scenarios, and rigorous maintenance requirements outlined in this guide, manufacturers can determine the ideal solution that aligns with their current and future production roadmap.

As the plastics industry advances toward greater sustainability, blending systems are crucial enablers. They facilitate the effective incorporation of post-consumer recycled (PCR) materials and ensure the precise, controlled use of critical additives. The right blending solution not only optimizes today’s material preparation workflows but also positions manufacturers to meet evolving material innovations and stringent regulatory demands.

The true value of a properly specified system is measured in its ability to mitigate risk. It locks in material control, minimizes defect rates, and establishes robust process consistency—these are the foundational elements that contribute to long-term competitive advantage in high-specification manufacturing.

What is the function of blender mixer?

The essential function of a blender or mixer is to act as the precision material preparation center for the injection molding process. It performs two critical tasks simultaneously before the material enters the machine throat:

- Precision Dosing (Metering): Ensuring the base resin and all additives (colorants, stabilizers, fillers, regrind) are dosed at the exact, target ratio, often achieving an accuracy of in modern gravimetric systems.

- Material Homogeneity (Mixing): Applying the necessary mechanical energy (either distributive or shear mixing) to ensure all components are thoroughly and uniformly dispersed.

This dual role is non-negotiable for guaranteeing product quality consistency and optimizing material usage.

What’s the difference between a blender and a mixer?

In the plastics processing industry, the terms blender and mixer are often used interchangeably to refer to the complete, integrated unit.

However, a technical distinction can be made based on the primary function:

- A Blender focuses on the precision metering and dosing aspect—the initial step of accurately measuring the required amount of each component (e.g., using load cells in a gravimetric system).

- A Mixer refers to the mechanical section designed to achieve physical homogeneity—the final step where components are agitated by blades or screws (using shear or distributive action) to create a uniform melt feed.

In a modern, single-unit system, these functions are inseparable and perform sequentially to deliver the final prepared material.

Ready to Optimize Your Blending Process?

Our experts can analyze your current setup and recommend the ideal blending solution for your specific application requirements.