What is a 400-Ton Injection Molding Machine?

A 400-ton injection molding machine is one that can exert a maximum clamping force of 400 tons (approximately 3,560 kN) during the plastic injection process.This force is the mechanism that holds the two halves of a mold securely closed during the manufacturing cycle. Its function is critical—it must counteract the immense pressure generated as molten thermoplastic material is injected into the mold cavity. By maintaining this 400-ton lock, the machine prevents the mold from separating, which in turn eliminates defects like flash (excess material seeping from the mold’s parting line) and ensures the final product meets precise dimensional specifications.

Structurally, any injection molding machine is comprised of two main components: the Injection Unit and the Clamping Unit. The injection unit is responsible for plasticizing (melting) the raw thermoplastic pellets and injecting this molten material into the mold. The clamping unit is what delivers the 400-ton force; it manages the opening, closing, and locking of the mold for each cycle. Therefore, the “400-ton” rating is the defining measure of the clamping unit’s power and capacity.

Modern 400-ton machines utilize different drive technologies to generate this force and execute machine movements. These are primarily categorized as:

- Hydraulic: Robust systems known for high clamping force generation and durability.

- All-Electric: Offer exceptional precision, high speed, and energy efficiency, as power is consumed only when motion is required.

- Hybrid: Combine the strengths of both, often using an electric drive for the injection unit (for precision) and a hydraulic drive for the clamping unit (for power).

Regardless of the drive type, these machines are governed by advanced control systems (often PLC or CNC-based) that manage every process parameter—from injection speeds and pressures to temperatures and cooling times—to ensure high levels of part-to-part repeatability and operational efficiency.

Product Applications of 400-Ton Machines

The 400-ton press is the essential workhorse for components that require a balance of medium-to-large size, high cavitation, structural integrity, and precise control.

High-Volume Packaging and Containers

For parts like these 650ml square snack boxes (200g), the 400T machine’s advantage lies in its high production capacity. It provides the necessary platen size and clamping capacity to efficiently run a six-cavity mold (cycle time: 15 seconds). Smaller presses typically have only two cavities, meaning the 400T effectively triples production, minimizing unit costs and maximizing return on investment.

Structural and Thick-Walled Components

For demanding structural items like the Children’s Folding Stool (400g) with thick walls (~ 3 mm), the machine guarantees safety and integrity. The robust 400-ton clamping force is essential to counteract high injection pressures, ensuring uniform locking across the mold. This prevents critical defects like flash and internal sink marks, which compromise the part’s stability.

Automotive and Precision Parts

When producing technical parts such as the Automotive Dashboard Bracket (320g) requiring high tolerance (±0.05 mm), the 400T is the capital-efficient choice. It delivers the required precision and repeatability without the unnecessary high capital expenditure and increased energy consumption associated with an “over-specced” 600T machine.

Deep-Draw and Large-Stroke Items

For deep parts like the 20L Storage Box (450g), the crucial factor is mechanical travel. The 400T machine is required because its design provides the generous mold opening stroke and extended ejection stroke (~ 700 mm). Smaller machines physically lack the necessary daylight to mold and retrieve such deep components successfully.

Consumer Electronics Injection Molded Parts

For a 65W charger housing (180g) requiring an 8-cavity output and a mirror-like finish, the fully electric 400T was the ideal choice. The machine is rigid enough to accommodate large molds, while the electric drive provides ultra-high speed and precise pressure control, achieving a perfect exterior surface finish within a fast 18-second cycle.

Note: The 400-ton injection molding machine is particularly well-suited for thin-wall molding applications.

Pro Tip:

Servo-Hydraulic Press: Optimal for applications demanding a blend of versatility, robust clamping strength, and a lower initial investment, offering a highly cost-effective solution.

All-Electric Injection Molding Machine: Ideal for precision-critical industries such as medical and electronics, characterized by exceptional accuracy, low energy consumption, and stringent quality output.

Two-Platen Servo Press: Delivers key benefits through a reduced machine footprint, saving valuable factory floor space, and providing an extended mold opening stroke, essential for deep-draw component molding

Find the Perfect Application Solution

Our engineering team can help determine if a 400-ton injection molding machine is right for your specific product application.

Technical Specifications and Performance Parameters

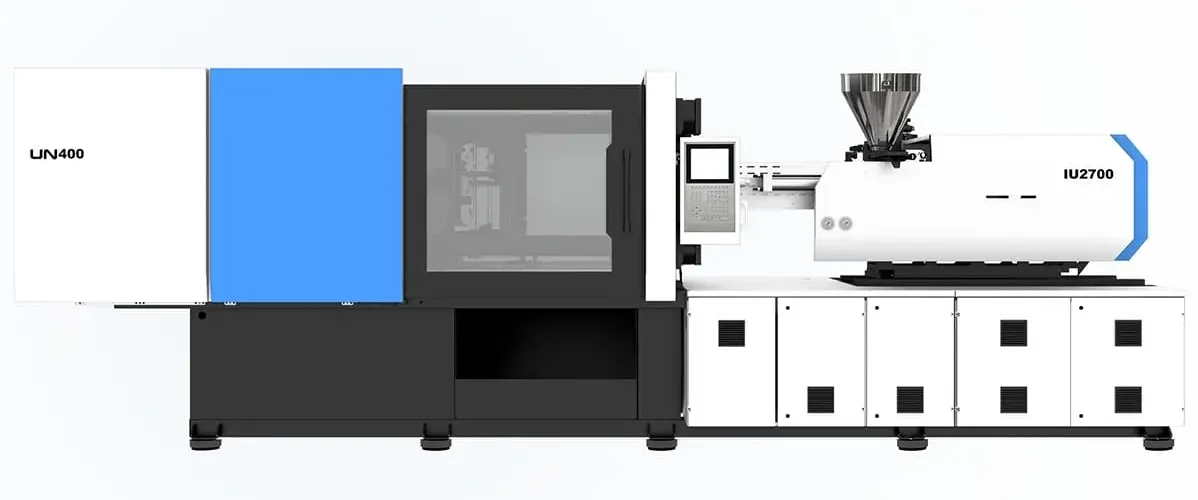

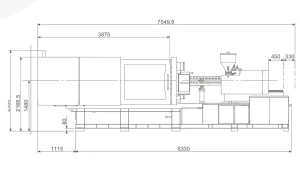

The 400-ton hydraulic injection molding machine stands as a reliable mid-range workhorse, offering critical flexibility for diverse production needs. The following specifications represent the industry standard and typical operational envelope for a high-performance model, such as the UN400-M7/IU2700 series. For engineers, mastering these specifications is the first step toward optimal tool and application matching.

| Clamping Unit | Unit | UN400-M7 | ||

| Clamping Force | kN | 4000 | ||

| Mold Opening Stroke | mm | 710 | ||

| Min. Mold Height | mm | 260 | ||

| Max. Mold Height | mm | 750 | ||

| Max. Daylight | mm | 1460 | ||

| Tie Bar Space (HxV) | mm | 760×710 | ||

| Ejector Stroke | mm | 210 | ||

| Ejection Force | kN | 111 | ||

| No.of Ejector Pin Holes | / | 13 | ||

| Injection Unit | Unit | IU2700 | ||

| A | B | C | ||

| Screw Diameter | mm | 68 | 76 | 84 |

| Screw L/D Ratio | L/D | 22 | 20 | 20 |

| Theoretical Shot Volume | cm³ | 1198 | 1497 | 1829 |

| Shot Weight(PS) | g | 1091 | 1362 | 1664 |

| Injection Rate | g/s | 303 | 378 | 462 |

| Injection Pressure | MPa | 225 | 180 | 147 |

| Plasticizing Capacity (PS) | g/s | 58.4 | 68.2 | 79.3 |

| Screw Rotation Speed | rpm | 168 | ||

| General Data | Unit | IU2700 | ||

| Heater Power | kW | 27/31 | ||

| Motor Power | kW | 54.30 | ||

| Oil Tank Capacity | L | 540.00 | ||

| Theoretical Weight | t | 15.40 | ||

| Machine Dim.(L×W×H) | m | 7.45×1.7×2.2 | ||

These precise specifications confirm the 400-ton machine’s position as a powerful, yet resource-conscious choice for expanding production capabilities across critical sectors like automotive and durable goods.

Comparative Analysis: 400T vs. Adjacent Tonnages

Informed equipment sizing is a critical business decision that directly impacts operational costs and long-term production flexibility. This comparative analysis positions the 400-ton machine against its immediate neighbors, the 300T and 500T classes, to provide clarity on economic trade-offs and technical capacity limitations. The 400T serves as the optimal baseline for assessing investment efficiency.

| Parameter | 300-Ton Machine | 400-Ton Machine | 500-Ton Machine |

| Tie Bar Spacing (H x V) | 670×620 mm (Approx.) | 760 ×710 mm (Approx.) | 830 × 780 mm (Approx.) |

| Typical Part Weight / Shot | Up to 1.2 kg/ 1200 g | Up to 2.0 kg / 2000 g | Up to 3.0 kg / 2500 g |

| Relative Investment Cost | 80 – 85% of 400T | Baseline (100% ) | 120 – 130% of 400T |

| Energy Consumption (Relative) | 75 – 85% of 400T | Baseline (100% ) | 125 – 140% of 400T |

300-Ton Machine: This class is highly effective for high-speed, medium-size component production. Its primary limitation is the Tie Bar Spacing, which restricts the physical size and cavitation of molds, often confining it to consumer electronics or smaller automotive inserts. The lower investment and energy use make it suitable only if component size and cavity count are strictly below the 400T threshold.

400-Ton Machine: The Strategic Equilibrium. The 400T press dramatically widens the acceptable mold envelope, allowing for high-cavitation medium-sized parts or large, complex components (e.g., appliance panels, medium industrial containers). Its proportional increases in investment and energy consumption are offset by the significantly higher production capacity (more cavities) and the ability to process much larger, structurally demanding parts. This makes it the most flexible asset.

500-Ton Machine: This machine is a dedicated tool for consistently large production. While it offers the maximum shot weight and mold capacity, the 20 – 30% higher investment cost and substantial increase in operational expenditure (energy, footprint) must be justified by the continuous production of components that physically cannot fit on a 400T press (e.g., full-size industrial pallets, large furniture parts). Using a 500T when a 400T suffices results in significant capital inefficiency.

Conclusion: The 400-ton machine represents the optimal balance point for manufacturers seeking maximum production versatility and the most efficient allocation of capital. It offers sufficient capacity for mid-to-large component manufacturing while skillfully avoiding the high overhead and rigidity of application typically associated with the 500-ton class and above.

Conclusion

The 400-ton injection molding machine stands as a critical inflection point in the equipment spectrum—a true strategic asset. It demonstrates robust capability for substantial components and complex, high-cavitation molds, while remaining economical for efficient, medium-to-high-volume production. Its well-earned title as the “King of Mid-Sized Machines” is affirmed by an exceptional balance of versatility, capacity, and operational cost efficiency across diverse industries.

Innovations in manufacturing technology continually enhance the capabilities of these machines. Modern 400-ton systems now routinely integrate advances such as Servo-Hydraulic drives and sophisticated Two-Platen designs, delivering superior energy optimization and a reduced footprint. These technological enhancements ensure that a precisely specified 400T machine remains a powerful component of any forward-thinking production strategy.

Optimal machine selection in today’s dynamic industrial landscape necessitates a deep, data-driven analysis. It is crucial to look beyond the initial price tag and comprehensively assess the machine’s full economic potential, diligently balancing technical capabilities with long-term operational sustainability and capital efficiency. By conducting a thorough analysis of specific production requirements against detailed machine specifications, companies can confidently select the 400-ton system that will deliver maximum value throughout its entire service life.

Ready to Find Your Ideal 400-Ton Solution?

Our team specializes in matching manufacturers with the perfect injection molding equipment for their specific requirements. Contact us for a comprehensive consultation.