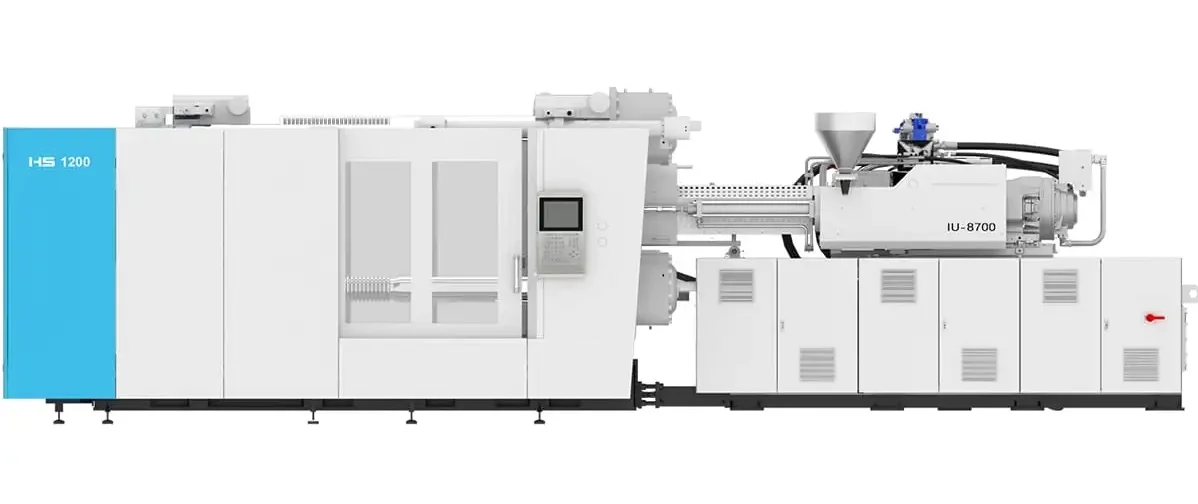

Within this spectrum, the 1200-ton injection molding machine stands at a strategic intersection, offering the substantial clamping force required for medium-to-large products while balancing efficiency and operational flexibility. This class of injection molding machine consistently delivers robust molding performance for diverse applications, from automotive bumpers and appliance housings to industrial containers, where dimensional stability and integrity are paramount.

This article provides a technical exploration of the 1200-ton injection molding machine’s defining specifications and examines its core applications across key industries. We will outline the essential criteria to determine if this powerful machine effectively addresses your specific production requirements.

Technical Features of 1200-ton Injection Molding Machines

The 1200-ton category is engineered for sustained, high-volume production of large plastic components, requiring a precise synergy of mechanical power, hydraulic responsiveness, and digital control. Understanding the technical architecture is key to assessing a machine’s true potential.

The 1200-ton category is typically configured with an advanced Two-Platen (2P) Clamping System. This modern design, compared to traditional toggle systems, significantly reduces the machine’s overall footprint (often by 15% to 20%), enhancing space utilization in a factory setting. Furthermore, the 2P design ensures superior platen parallelism and simplified access, which directly contributes to quicker mold changeovers and reduced long-term maintenance costs.

| Clamping Unit | Unit | HS1200 |

| Clamping Force | kN | 12000 |

| Mold Opening Stroke | mm | 2050/1400 |

| Min. Mold Height | mm | 600 |

| Max. Mold Height | mm | 1250 |

| Max. Daylight | mm | 2650 |

| Tie Bar Space (HxV) | mm | 1350×1200 |

| Ejection Stroke | mm | 350 |

| Ejection Force | kN | 230 |

| Max.Mould Weight | t | 20 |

Core Clamping Unit Specifications and Geometry

The defining factor remains the 1200-ton (approximately 12,000 kN) clamping force. This substantial force is not merely a capacity figure; it is the foundation for maintaining dimensional consistency and preventing flash on parts with large projected areas. The sheer size of the machine is constrained by the following key geometric metrics, which dictate mold compatibility and throughput:

High-Performance Injection Unit

The injection unit is responsible for the critical processes of plasticizing and metering the polymer melt. On a 1200-ton machine, the unit must handle substantial shot volumes while maintaining thermal homogeneity and velocity control.

| Injection Unit | Unit | IU5200 | IU8700 | IU13700 | ||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 80 | 90 | 100 | 100 | 110 | 120 | 120 | 130 | 140 |

| Screw L/D Ratio | L/D | 24.8 | 22 | 19.8 | 24.2 | 22 | 20.2 | 24 | 22.2 | 20.6 |

| Theoretical Shot Volume | cm³ | 2262 | 2863 | 3534 | 3927 | 4752 | 5655 | 6503 | 7632 | 8851 |

| Shot Weight (PS) | g | 2058 | 2605 | 3216 | 3574 | 4324 | 5146 | 5918 | 6945 | 8055 |

| Injection Rate (PS) | g/s | 549 | 694 | 857 | 686 | 830 | 988 | 1050 | 1232 | 1429 |

| Injection Pressure | MPa | 233 | 184 | 149 | 222 | 183 | 154 | 211 | 180 | 155 |

| Plasticizing Capacity (PS) | g/s | 59 | 74 | 92 | 122 | 147 | 175 | 144 | 169 | 196 |

| Screw Rotation Speed | rpm | 150 | 160 | 110 | ||||||

| General Data | Unit | IU5200 | IU8700 | IU13700 |

| Heating Capacity | kW | 52 | 67 | 98 |

| Motor Power | kW | 94+3 | 112+4 | 159+4 |

| Oil tank capacity | L | 1050 | 1300 | 1800 |

| Theoretical Weight | t | 46 | 48 | 52 |

| Machine Dim.(L×W×H) | m | 9.7×3.4×2.9 | 9.9×3.4×2.9 | 11.3×3.4×2.9 |

Facilities and Operational Metrics

Beyond clamp force and shot size, the sheer size of a 1200-ton machine requires careful consideration of operational metrics and facility requirements. These general parameters impact installation costs, ongoing maintenance, and overall electrical infrastructure planning.

The following data, using a typical large machine range (IU5200 – IU13700), illustrates the significant footprint and electrical requirements inherent in this tonnage category:

Need Detailed Technical Specifications?

Our engineering team can provide comprehensive specifications tailored to your manufacturing requirements.

Application Scenarios of 1200-ton Injection Molding Machines

The 1200-ton injection molding platform is strategically employed when product specifications exceed the capacities of mid-range machinery, demanding superior clamping force for large projected areas, complex geometry, or high-volume output of durable components. These machines are essential tools for overcoming common manufacturing challenges related to large-part molding.

Automotive Sector: Structural and Aesthetic Demands

In the automotive industry, 1200-ton machines are critical for producing components that require a delicate balance of high structural strength, lightweighting, and impeccable surface finish. The substantial clamping force ensures the integrity of large molds and the precise replication of textures and features, even when molding demanding materials like PP/Talc or engineering thermoplastics.

- Exterior Systems: Full-size Bumper Fascias and Front-End Modules, where consistent wall thickness and high impact resistance are non-negotiable.

- Interior Sub-Assemblies: Large Instrument Panels and complex Dashboard Carriers that require dimensional stability across wide temperature variations.

- Aero/Acoustic Components: Large underbody shields or wheel arch liners demanding high rigidity and noise reduction features.

Consumer and Industrial Enclosures (CE & HA)

This category encompasses large housings where both structural support and visual appeal are paramount. Manufacturers rely on the 1200-ton capacity to mold these items without sink marks or warping.

- Major Home Appliance Liners: Refrigerator Interior Liners and Door Panels requiring vast surface areas and food-grade material processing consistency.

- Air Conditioner Casings: Large Outdoor Unit Housings and indoor air handler components made from weather-resistant polymers.

- Commercial Furniture: Single-shot molding of large, high-strength Chair Frames and Table Bases for public and commercial settings.

Material Handling and Infrastructure: Durability and Volume

The requirement for extreme durability, high load-bearing capacity, and low cycle times for high-volume logistics products makes this tonnage essential.

- Logistics Pallets: Production of Standard and Heavy-Duty Industrial Pallets (e.g., 1200 mm × 1000 mm), where uniform filling and zero-flash are vital for automatic handling systems.

- Waste Management: Large-scale Industrial Bins and Commercial Waste Containers molded from recycled or high-density polyethylene (HDPE), designed for outdoor environmental resistance.

- Construction Infrastructure: Molding of large-diameter Drainage System Components and Utility Manhole Covers that require significant wall thickness for ground pressure resistance.

Specialized Large-Format Applications (Medical/Tech)

While often associated with smaller components, certain advanced industries require this large tonnage for specialized, large-format equipment.

- Medical Equipment Housings: Precision molding of large, specialized Enclosures for Imaging Equipment (e.g., CT/MRI units), where cosmetic requirements meet strict material and regulatory standards.

- Large Display Backlights/Frames: Molding structural frames or optical components for commercial-grade, Extra-Large Displays or Digital Signage.

Explore Industry-Specific Applications

Discover how a 1200-ton injection molding machine can optimize production for your specific industry needs.

Reasons for Selecting a 1200-ton Injection Molding Machine

Choosing the right injection molding machine capacity is crucial, impacting production capacity, operating costs, and product quality. 1200-ton injection molding machines offer unique advantages, making them an ideal choice for many manufacturing scenarios.

Technical Necessity: Clamping Force and Geometry

The primary determinant for selecting the 1200-ton class is the part’s geometry, specifically the projected area and the required in-mold pressure.

- Clamping Force Calculation: The machine’s 1200-ton capacity is technically justified when the product’s total projected area, multiplied by the required cavity pressure (typically 3-7 tons/in² or 46-108 MPa), dictates this high lock force to prevent flash.

- Dimensional Scale: The optimal use is for large single components exceeding one meter in dimension (e.g., automotive fascia, large appliance panels) or large, high-cavitation molds that maximize the machine’s platen area and shot volume.

- Flow and Filling Challenges: Parts characterized by thick walls or long, complex flow paths require sustained, high injection pressures, which are reliably delivered by the 1200-ton unit’s robust hydraulic system.

Production Efficiency and Material Demands

The 1200-ton machine must demonstrate superior efficiency compared to running the same product on smaller or multiple machines.

- Throughput and Cycle Optimization: The machine is suited for high-volume production runs where cycle time reduction is critical. Its ability to handle large molds often facilitates using multi-cavity tooling for higher parts-per-hour output.

- Advanced Material Processing: Selection is often driven by the need to process demanding compounds such as high-viscosity engineering plastics (PC, LCP) or fiber-reinforced composites. These materials necessitate the higher injection pressure and robust screw torque available in this size class to ensure complete filling and consistent fiber orientation.

- Mold Protection and Longevity: Given the high cost of large-format tooling, the machine’s advanced features, such as adaptive mold protection and precise platen parallelism, become crucial criteria to safeguard capital investment in the mold itself.

Economic Justification and ROI

The economic rationale for this major capital expenditure lies in achieving a lower Total Cost of Ownership (TCO) and a strong Return on Investment (ROI).

- Part Consolidation Strategy: Investing in the 1200-ton capacity allows for the consolidation of multiple smaller assembled parts into one single, complex component. This strategy drastically reduces assembly labor, inventory management, and overall part count, often being the single largest driver of the ROI.

- Energy Consumption Analysis: Modern 1200-ton machines with servo-driven hydraulics offer substantial operational cost savings. The selection process must involve a rigorous comparison of energy consumption per kilogram of processed material (kW per kg) versus legacy equipment.

- Operational Scalability: Choosing a machine with the capacity for both large single-cavity molds and slightly smaller, high-cavitation molds offers operational flexibility, future-proofing the investment against potential changes in product demand or design iterations.

Advantages and Limitations of 1200-ton Injection Molding Machines

While 1200-ton injection molding machines offer substantial benefits for many manufacturing scenarios, it’s important to consider both their advantages and limitations when evaluating them for specific applications.

Core Technical Advantages

The benefits of utilizing a machine in the 1200-ton class stem directly from its scale and integrated modern technology:

- Superior Part Quality on Large Scale: The massive clamping force ensures minimal flashing and enhanced dimensional stability across large projected areas, minimizing warpage and defect rates typically associated with large components.

- Production Consolidation: The large platen size and shot capacity support complex multi-cavity tooling or the integration of multiple smaller parts into a single mold, directly leading to a more streamlined assembly process and logistics.

- Operational Efficiency: Modern configurations featuring servo-driven hydraulics deliver verifiable energy consumption reductions (typically 20% to $80%) when compared to traditional, continuously running fixed-displacement pump hydraulic systems.

- Process Stability: Advanced, closed-loop control systems facilitate the consistent processing of challenging materials, including thick-walled parts and fiber-reinforced composites, maintaining precise parameter control throughout the long cycle.

Investment Risks and Operational Constraints

The scale of the 1200-ton machine introduces unique operational and financial constraints that must be factored into the TCO model:

- High Capital Outlay: The initial acquisition cost is substantial, and this is compounded by the significantly higher cost of large-format molds, making the investment dependent on a guaranteed, long-term product lifecycle.

- Changeover Complexity: Due to the weight and size of the tooling and platens, mold changeover and setup times are inherently longer than for mid-range machines, impacting operational flexibility and making it inefficient for low-volume or rapid-turnaround jobs.

- Inventory and Demand Risk: The high output capacity creates a scenario where unexpected dips in product demand can quickly lead to high levels of finished-goods inventory and a higher financial exposure should the component design require sudden modification.

- Specialized Human Capital: The complexity of the advanced control systems and the scale of the machinery mandate specialized technical training for operators and maintenance personnel, representing an ongoing investment in human capital.

Critical Facility and Infrastructure Prerequisites

Successful implementation of a 1200-ton machine requires extensive preparation of the manufacturing environment:

- Structural and Space Demands: The machine’s net weight (approx. 40-52 tons) and large footprint (up to 12 meters in length) necessitate reinforced concrete flooring engineered to withstand significant static and dynamic loads.

- Utility Infrastructure: Requires a high-capacity electrical service and robust cooling water supply for both the hydraulic system and, critically, for the large mold cooling circuits, which often demand specialized high-flow Temperature Control Units (TCUs).

- Maintenance Logistics: Comprehensive maintenance programs are essential. Due to the size of major components (e.g., tie bars, platens), procedures are more complex, and unscheduled downtime is exponentially more costly. Facilities must allocate space and resources for larger material handling equipment (overhead cranes, forklifts) to manage major component replacement.

Conclusion

The 1200-ton injection molding machine solidifies its position as a critical manufacturing asset for industries that depend on the production of large-format, structurally robust, and cosmetically demanding polymer components. Its strategic value lies in successfully bridging the critical capacity requirement for parts that exceed the molding threshold of 1000 tons, without incurring the excessive capital and facility costs associated with ultra-large equipment.

As detailed, the combination of substantial clamping force, optimized shot capacity, and integrated servo-hydraulic technology delivers tangible benefits: enhanced part quality, superior process control, and a verifiable reduction in energy consumption per unit of production. This capacity is paramount for ensuring dimensional integrity in large components across sectors like automotive exterior systems, large appliance chassis, and heavy-duty logistics equipment.

The decision to invest in this class of machine is fundamentally an exercise in strategic capital deployment. Achieving a high return on investment hinges on a rigorous pre-installation assessment of the mold’s projected area, the facility’s structural and utility readiness, and the long-term volume stability of the product line.

Ultimately, for manufacturers whose future growth is tied to part consolidation, increased structural requirements, or the sustained high-volume output of medium-to-large products, the 1200-ton injection molding machine offers a powerful, technologically advanced, and economically justifiable solution to meet the most demanding production specifications.

Evaluate Your Manufacturing Requirements

Our team can help determine if a 1200-ton injection molding machine is the right fit for your production needs.