Your Solutions Partner, Not Just a Machine!

Top plastic injection molding machine manufacturer

- From IMM Manipulator to Full Setup: Your End-to-End Production Solution.

- Ready on Arrival: Pre-Tested & Secured Machines with Reliable Delivery.

- 24/7 Expert Support to Keep Your Production Running.

- For beginners: our trusted suppliers provide pellets from molds.

With years of hands-on experience, PlasticMech navigate tough production challenges to deliver reliable outcomes and ensure your project succeeds from day one.

PlasticMech offer flexible OEM manufacturing and full ODM system design, providing partnerships to build or co-create your ideal, application-specific production solution.

Your project is managed by a dedicated engineer, a single point of contact who ensures clear communication and flawless execution from start to finish.

All-Electric, Hybrid, or Hydraulic?

We offer a full range of All-Electric, Hybrid, and Hydraulic injection molding machines. Whether you prioritize precision and efficiency, powerful clamping force, or a balanced performance, we have the solution. Each system is engineered with distinct advantages in cost, energy use, and output. Let us help you select the perfect technology for your specific application.

Our Plastic injection molding machine

PlasticMech diverse lineup of plastic injection moulding machines provides tailored solutions, whether your priority is micro-precision, high-speed cycling, or large-part manufacturing. We integrate cutting-edge technology with robust engineering to ensure every model delivers unparalleled consistency and value. Find the perfect system to meet your requirements by exploring our IMM series below.

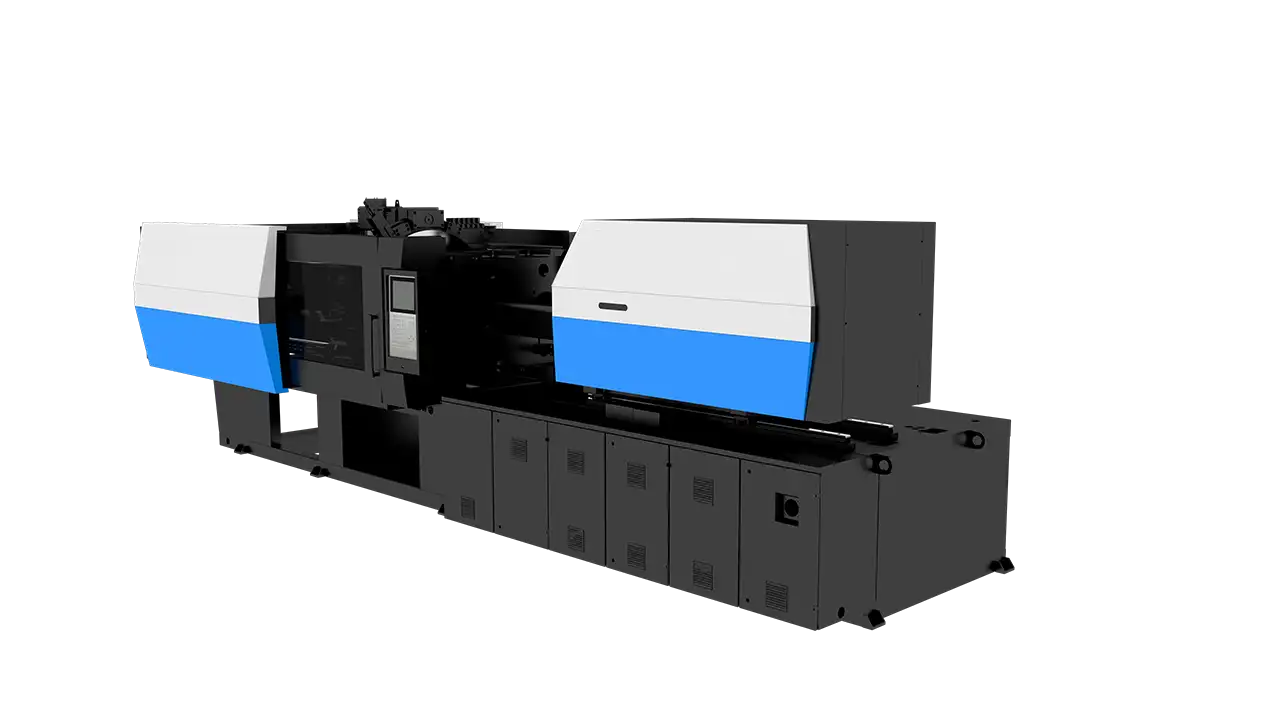

The framwork of modular concepts enrich the machine the magic expandability to the multi K and hybrid functions dedicated for the packaging, medical, auto and other engineering applications.

- Pictured: ES320 IMM

Application Area

- Clamping Position Repeatability < 0.01 mm

- Injection position accuracy <0.01 mm

- Repeatable accuracy of Injection motion 0.01%

- Injection max speed can reach 450mm/s

- Injection response speed <40ms

- Dry cycle time improved by 20%

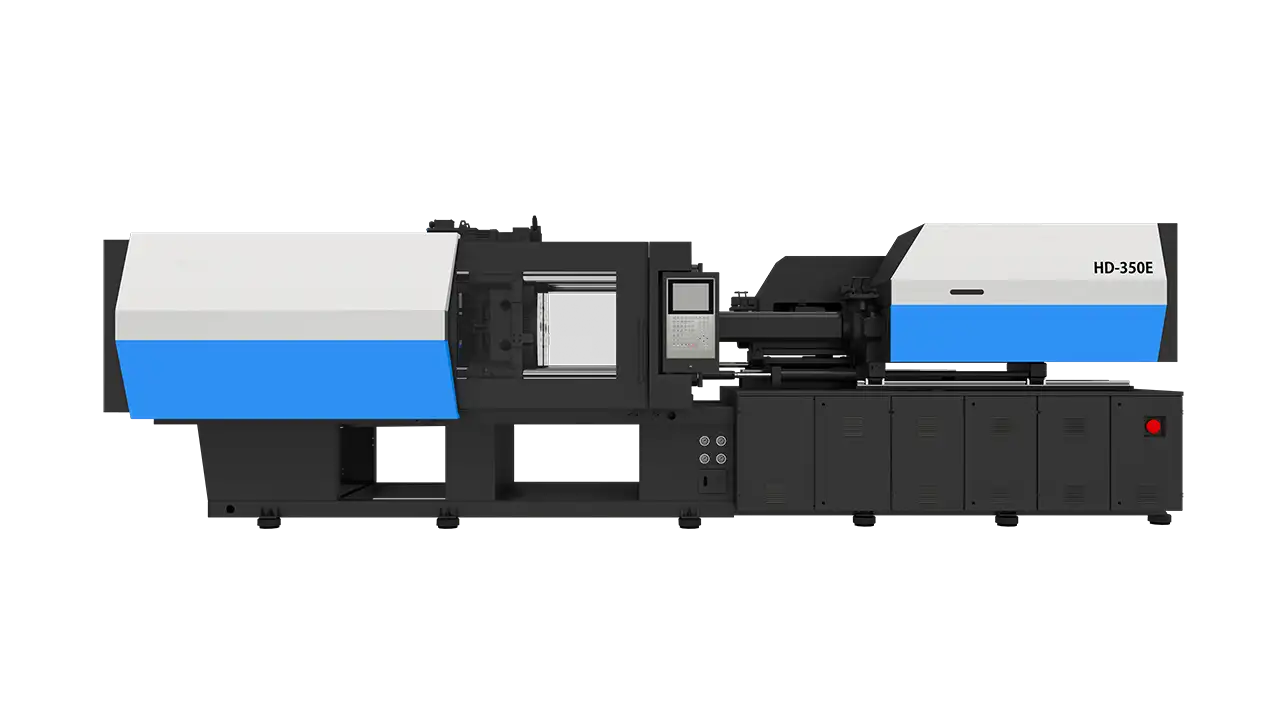

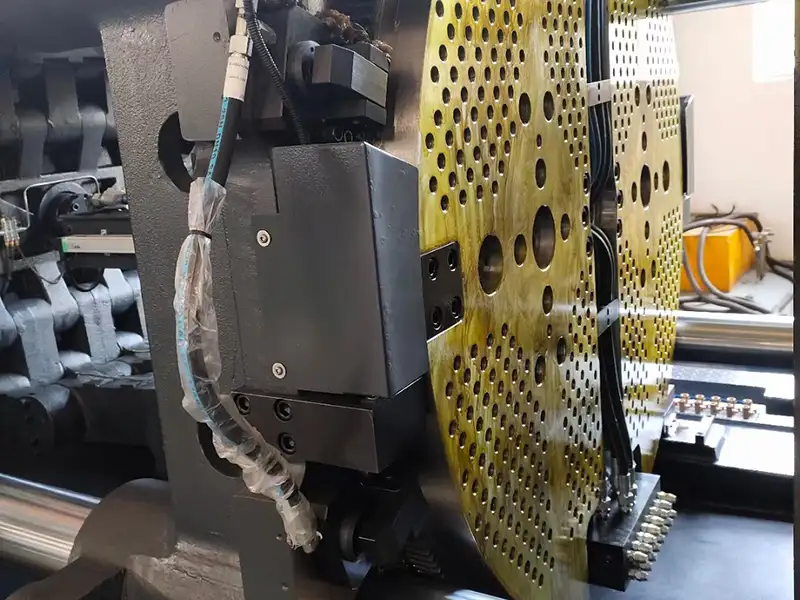

Flexible configuration matrix of the injection units ensures the various multi-color applications, and adapts to super-large cavity molds such as auto parts, home appliances, packaging, and electronics.

- Pictured: HD350 IMM

Application Area

- HD350 SPECIFICATIONS

- Clamping Force 3500kN

- Bearing Capacity of Rotary Platen 3.2t

- Ejection Stroke 150mm

- Ejection Force 49×2kN

- Max. Mold Installed Diameter 1223mm

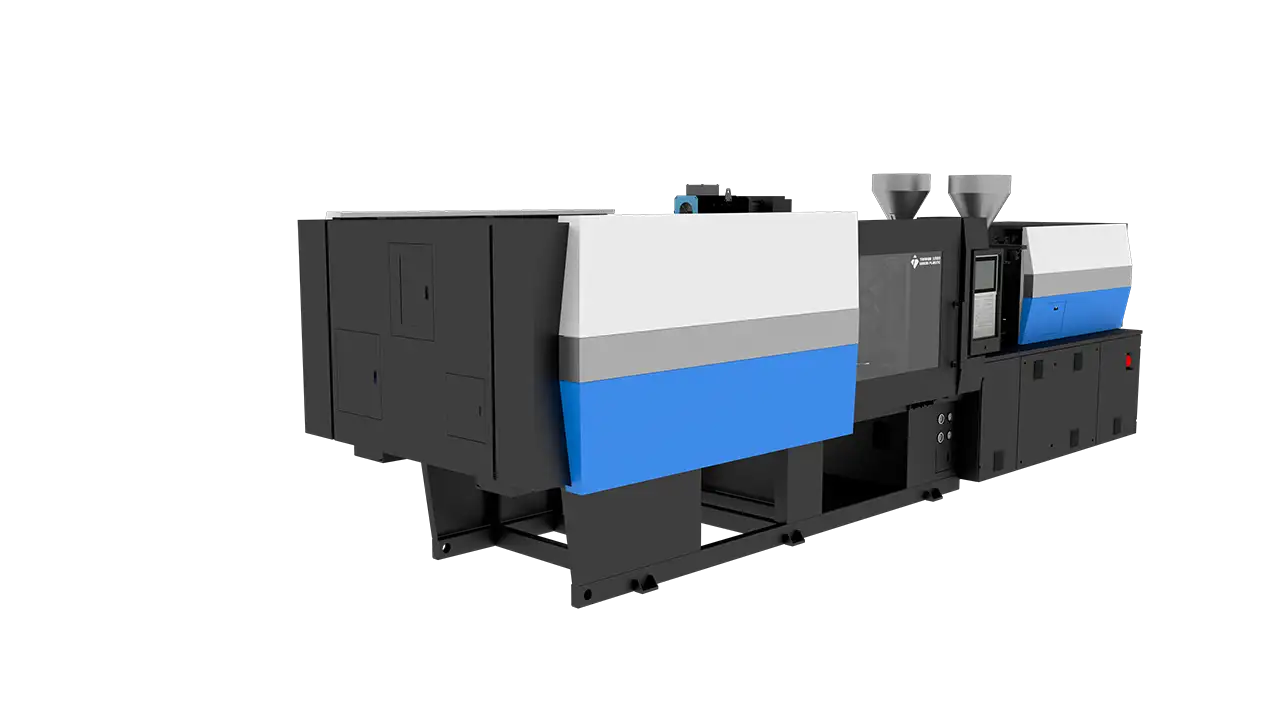

The whole injection molding machine has a compact structure, large mold opening stroke, and is suitable for super-large cavity molds such as auto parts, home appliances, logistics, and pipe fittings.

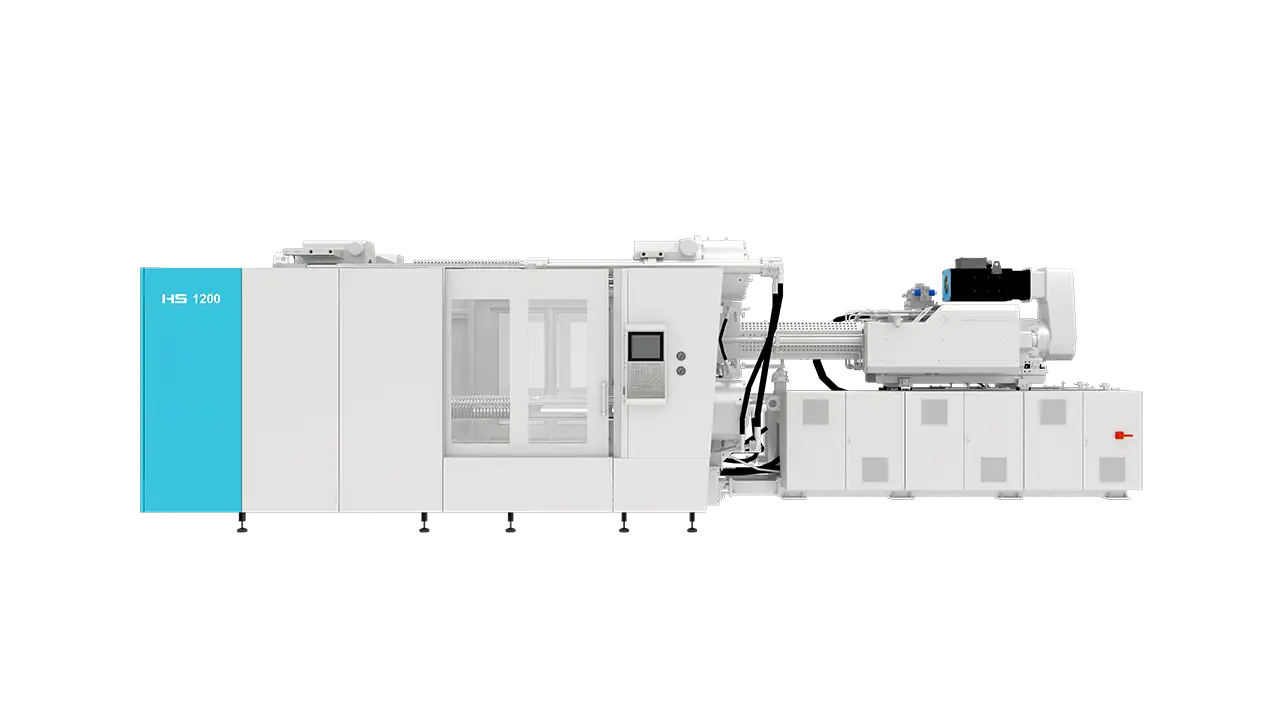

- Pictured: HS1200 IMM

Application Area

- Mold support weight increased by 15%

- Tie bar unbalanced load ≤4%

- The speed of switching the mold1000mm/s

- Injection repeatability ≤0.1%

- Product quality repeatability ≤0.3%

- Injection end-position repeatability ±0.2 mm

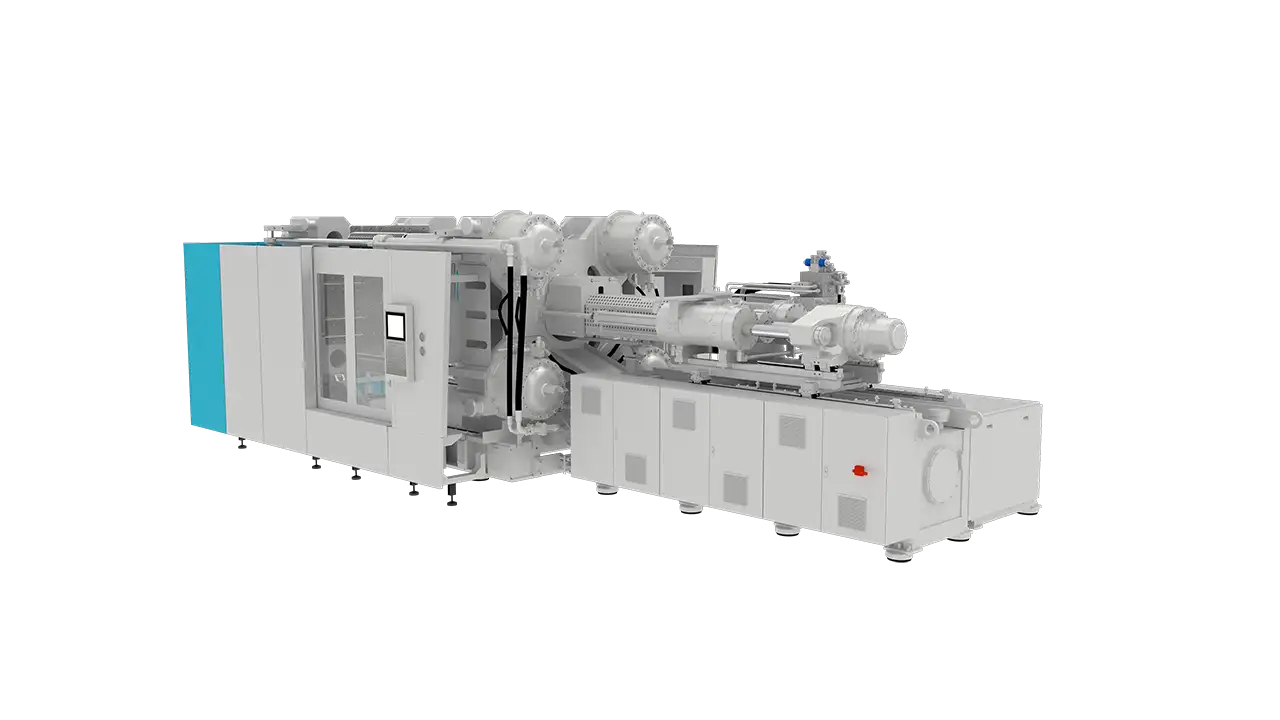

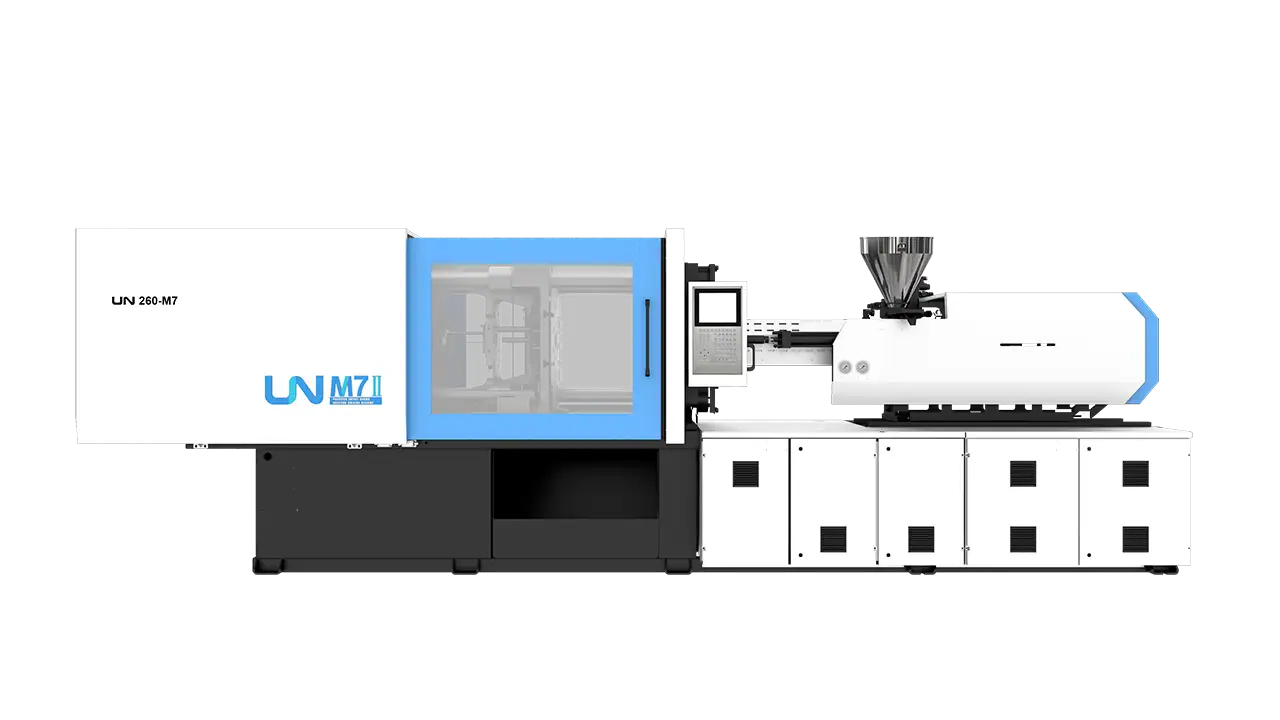

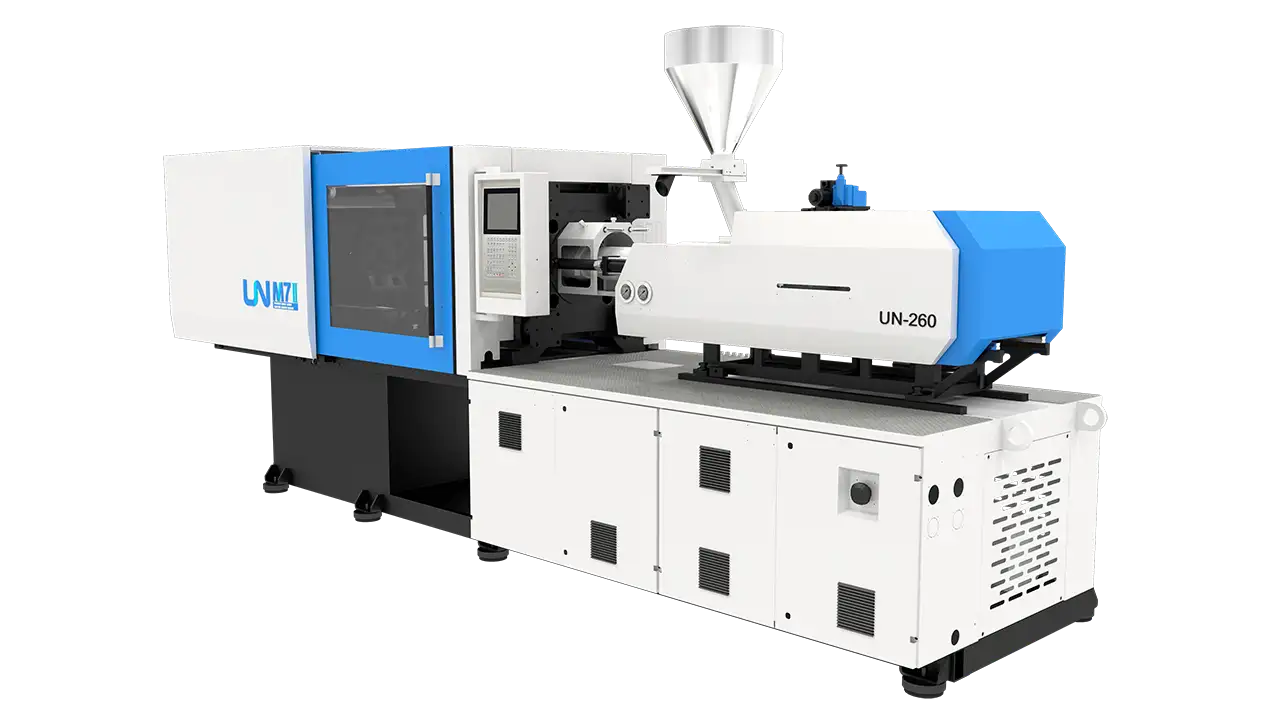

The UN series injection molding machines are developed with customer applications as the starting point. We prioritize reliable, stable, and efficient performance, while striving for exceptional detail and adaptability.

- Pictured: UN260 IMM

Application Area

- Mold open/close repeatability < 1 mm

- The parallelism of the template < 0.2mm

- Clamping force repeatability <1%

- Tie rod force deviation <+3%

- Injection repeatability: 3‰

- Melt-weight deviation <0.5%

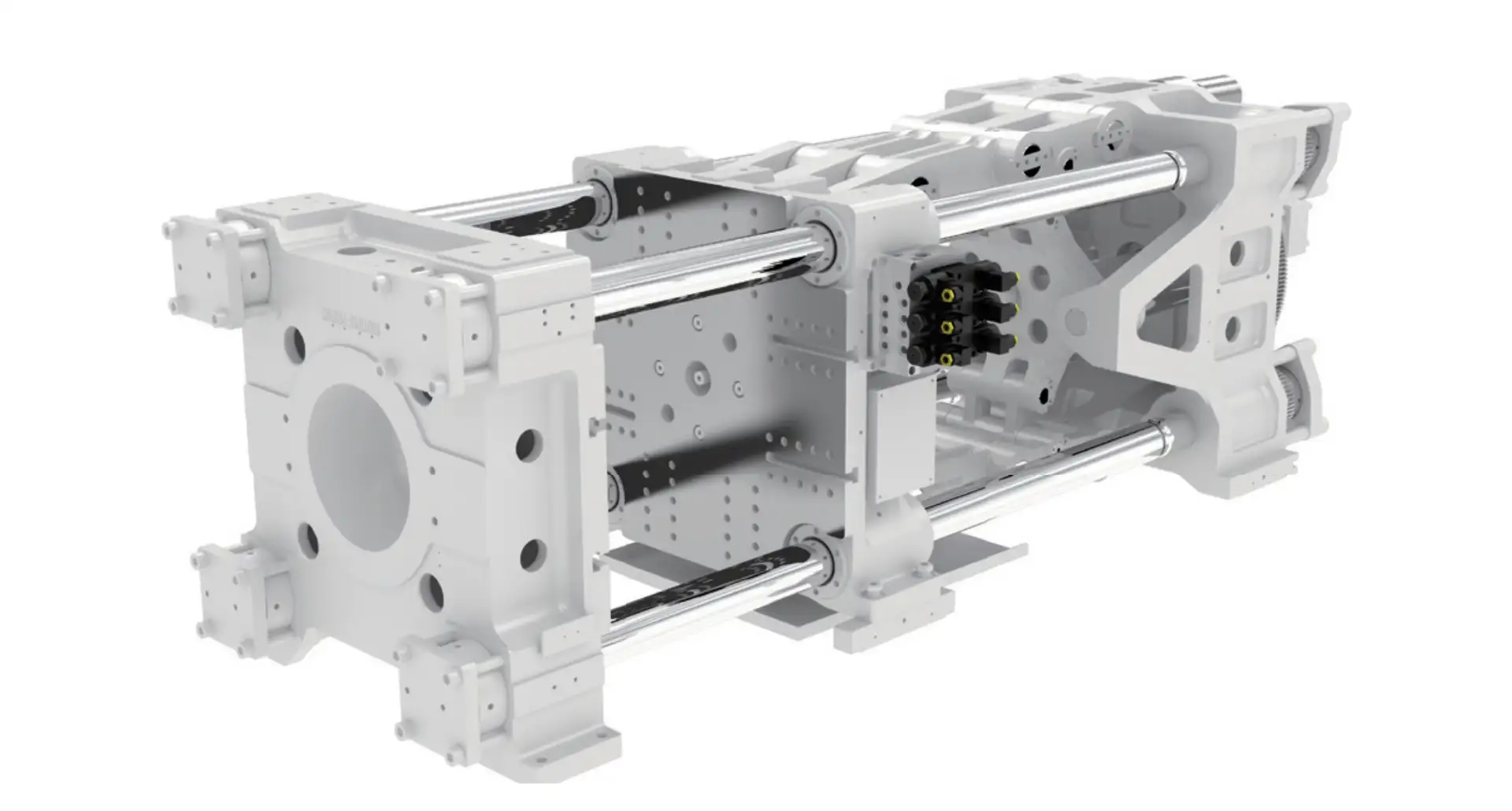

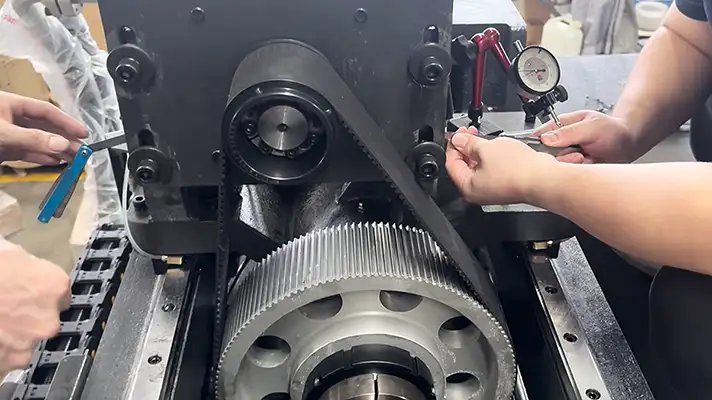

Employing finite element design and optimization to ensure stable, reliable operation. All series of platens feature T-slots to facilitate mold removal, improve efficiency, and extend platen service life.

- Pictured: UN260E-IU790 IMM

Application Area

- Max. injection speed 450 mm/s

- Max. screw speed 400 rpm

- Clamping force repeatability < 1%

- Injection position accuracy ≤ 0.05 mm

- Energy savings up to 20%

- Parallel plasticizing during mold opening

Providing customers with comprehensive, customized solutions for all aspects of injection molding machines, from design and production to optimization and after-sales support.

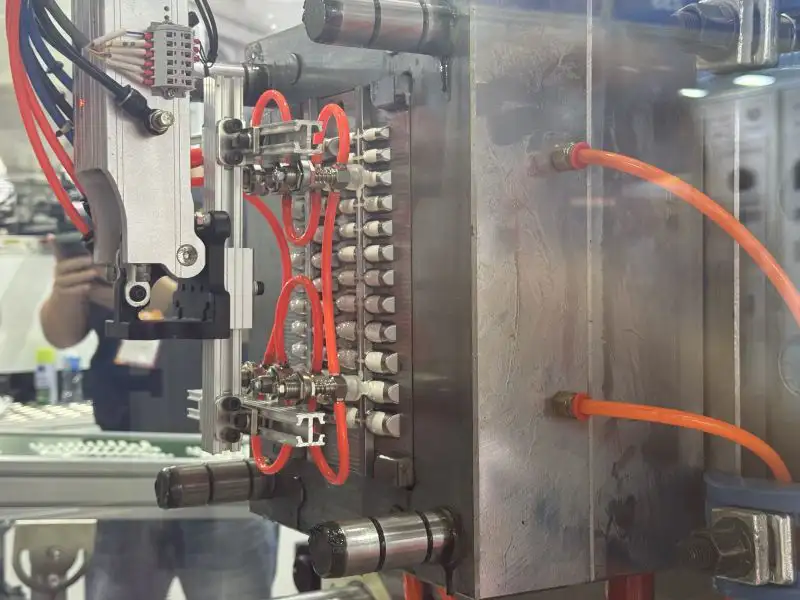

- Pictured: IMM clamping unit

People Always ask PlasticMech

Can your machine produce this?

The procurement process for a custom multi-component injection molding machine doesn’t begin with the machine itself, but rather with the part to be produced. A thorough understanding of the part’s geometry, material requirements, functional performance, and end use form the foundation for defining the IMM’s technical specifications. Factors such as shot volume, clamping force, mold complexity, automation requirements, and integration with auxiliary equipment all derive from the part’s characteristics. Only by clearly defining the part’s design and production goals can the appropriate machine configuration be determined to ensure technical feasibility and cost-effectiveness.

- From Feasibility to Compliance

- Assess product feasibility by matching part geometry with machine capabilities.

- Integrate multiple materials to enhance function, aesthetics, and cost-efficiency.

- Meet industry-specific standards through deep technical and compliance expertise.

- Configuring Machines for Performance and Flexibility

- Precisely match clamping force and injection layout to customer molds.

- Select optimal multi-component transfer methods to balance complexity, speed, and cost.

- Process and Material Mastery

- Ensure material compatibility and strong, reliable bonding.

- Optimize process parameters and molding precision to improve efficiency and quality.

- Building a Automated Production Ecosystem

- Ensure full compatibility with pre-, in-, and post-molding auxiliaries.

- Integrate advanced robotics for automation and turnkey efficiency.

- Connect machines to MES/ERP for real-time data and smart manufacturing.

- Maximizing Value Through Cost and Return Analysis

- Quantify ROI and payback period to build a strong business case.

- Quality Support & Reliability

- Provide compliance and cleanroom capabilities to guarantee quality.

- Deliver responsive after-sales service, training, and spare parts support.

How PlasticMech Solves Challenges

My machine is too slow, and mold changeovers kill my productivity.

We know cycle time is money. Our All-Electric series delivers peak performance with injection speeds up to 450 mm/s and response times under 40 ms. Its optimized design cuts dry cycle time by 20% compared to standard machines—meaning more parts per hour and higher output.

My energy bills are out of control.

For customers facing high operational costs, our All-Electric machines deliver up to 80% energy savings over older hydraulics. For those needing hydraulic power, our modern UN Series uses efficient pump technology for an excellent cost-to-performance ratio, balancing power with responsible energy use.

I have high scrap rates because of inconsistent part quality.

In precision molding, inconsistent quality is unacceptable. Our All-Electric machines achieve clamping position repeatability of <0.01 mm and injection motion repeatability of 0.01%. This precision ensures the first part matches the last, slashing scrap and enabling the tightest tolerances.

Unplanned breakdowns and messy hydraulic maintenance are a constant headache.

Built for modern manufacturing, our UN Series Hydraulic IMMs deliver proven 24/7 durability with wear-resistant components that reduce upkeep. For a leak-free, cleanroom-friendly option, our All-Electric series offers lower maintenance and higher Overall Equipment Effectiveness (OEE).

We are losing time and money assembling parts that could be made in one piece.

That’s why we developed our Multi-Component IMMs. Rather than treating assembly as a separate cost, they eliminate secondary processes entirely. By forming a superior chemical and thermal bond in the mold, we boost part quality and cut cycle times by up to 50%—a strategic advantage that streamlines your entire production floor.

Long mold changeover times are one of our biggest sources of lost productivity.

We engineer our machines with Quick Mold Change (QMC) in mind, featuring automated die height adjustment, magnetic or hydraulic mold clamping, and quick-disconnect ejector couplings. Together, these turn a multi-hour manual process into one completed in a fraction of the time—keeping your machine making parts, not waiting for them.

Our services

Comprehensive solutions designed to maximize equipment efficiency, reduce errors, and minimize downtime—covering everything from training and preventive maintenance to rapid parts delivery and secure logistics.

solution

Provide pellet, mold, and robot sources.

Boost efficiency, cut personnel risks.

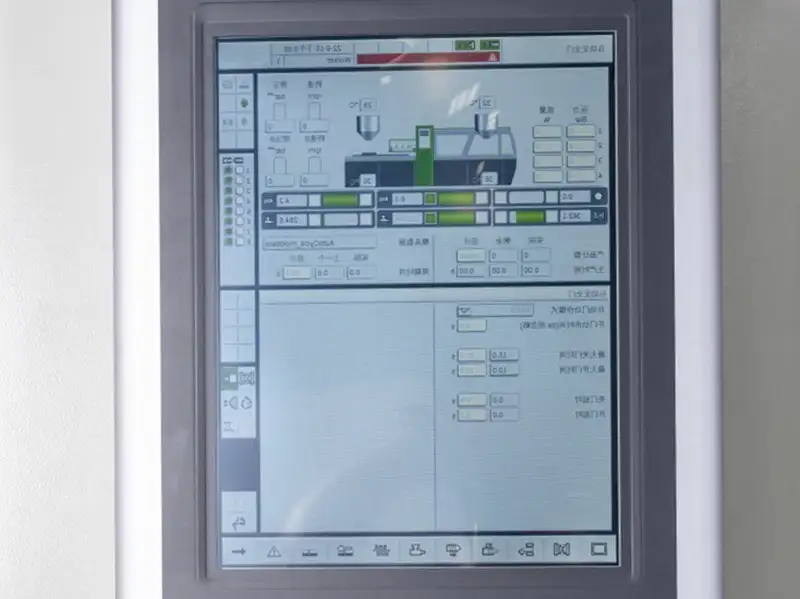

Simple operations

Operator & Maintenance Training.

Empower, reduce errors.

Stable quality

We act as an extension of your team.

High-quality output from the very first shot

Delivery

Supervise delivery process.

Secure machine and notify customer.

Test

Test the machine upon delivery.

Rust-preventive spray and oil after testing

Support

24/7 Remote Diagnostics & Support.

Return to production in minutes, not days

About Plastic Mech

PlasticMech deliver not just machines, but complete, value-driven solutions. With our manufacturing base in Ningbo and commercial office in Hangzhou, we serve a diverse international clientele.

We offer a comprehensive range of injection molding machines—reliable, precise, and energy efficient—with clamping forces from 90t to 6,600t. Our portfolio spans advanced Servo-Hydraulic, space-saving Two-Platen, and high-precision All-Electric series, plus solutions like Multi-Component Molding, In-Mold Labeling (IML), PET preform systems, and more.

Customer Satisfaction Exhibition Site

A dedicated space showcasing real-world applications, success stories, and live demonstrations, allowing customers to experience our solutions’ performance, reliability, and value firsthand.

What Our Happy Clients Say

We have extensive project experience and can tailor injection mold machine solutions to your specific needs, delivering exceptional quality with professional and attentive service.

Professional, enthusiastic and reliable IMM specialists

Common Questions

Most Popular Questions

Investing in a new injection molding machine is a significant decision, and we’re here to make the process as clear and simple as possible. If you don’t find your answer here, our team is always ready to help.

The most critical factor is your specific application. The part you are producing—its material, size, complexity, and required quality—will determine everything else, from the machine type (Hydraulic, All-Electric, Multi-Component) to the required clamping force and injection unit specifications. A thorough analysis of your product is always the first step.

The initial purchase price is simply the cost of the machine itself. Total Cost of Ownership (TCO) is a more important long-term metric that includes the initial price plus all operational costs over the machine’s life, such as energy consumption, maintenance, spare parts, and the cost of scrap/rejected parts. A machine with a lower initial price may have a much higher TCO over time.

With proper preventive maintenance and care, a high-quality industrial injection molding machine can have a productive life of 15 to 20 years or more. The longevity depends on the build quality, operating hours, and the quality of the maintenance program.

This depends entirely on your priorities:

All-Electric: Choose this for the highest precision, repeatability, energy efficiency, and cleanroom applications (e.g., medical, electronics).

Servo-Hydraulic: Choose this for applications requiring high clamping force, durability, and the best cost-to-performance ratio, especially for larger parts (e.g., automotive, storage containers).

Hybrid: This offers a balanced performance, combining the precision of an electric injection unit with the power of a hydraulic clamp, making it a versatile choice.

A general rule of thumb is to calculate the projected surface area of your part (in square inches or cm²) and multiply it by a material-specific factor (typically 2 to 8 tons per square inch). However, this is just an estimate. We highly recommend our Application & Process Engineering Support service, where our experts will perform a detailed analysis to determine the precise tonnage you need, ensuring optimal performance without overspending.

You should consider the shot size (to ensure you can inject enough material without degrading it), the screw design (general purpose vs. material-specific), and the injection pressure and speed capabilities required for your parts.

Stop Guessing Which Machine to Buy

We have seen too many companies get headaches from choosing the wrong machine. So I’ve summarized my experience into a “Core IMM Selection Checklist” to help you clarify your thinking and avoid common pitfalls. Fill out the form on the right, I will send you the checklist immediately, and I will personally review your project needs to offer a free expert consultation.

Get Free IMM Checklist

Tell us about your project and receive:

- Instant download of my "Core IMM Selection Checklist"

- A personalized, expert-led consultation from me