Your Solutions Partner, Not Just a Machine!

Injection molding Robot

Plastic Mech Robot Arm Division established in 2011, our Robot Arm Division provides intelligent, turnkey automation solutions for a diverse range of global industries, including Packaging, Medical, Automotive, Home Appliances, and 3C Electronics. We are dedicated to delivering highly integrated, secure, and sustainable automated and informatized systems for our clients worldwide.

In the rigid packaging sector, we are a vital and ultra-reliable partner to globally recognized brands. We serve a broad spectrum of sub-markets—from food and beverage to daily chemicals, industrial goods, and medical supplies. Our core mission is to continuously provide innovative, intelligent production line systems and packaging solutions uniquely tailored to the needs of each industry we serve.

With years of hands-on experience, PlasticMech navigate tough production challenges to deliver reliable outcomes and ensure your project succeeds from day one.

PlasticMech offer flexible OEM manufacturing and full ODM system design, providing partnerships to build or co-create your ideal, application-specific production solution.

Your project is managed by a dedicated engineer, a single point of contact who ensures clear communication and flawless execution from start to finish.

Top-entry Injection Robot (3-Axis Robot)

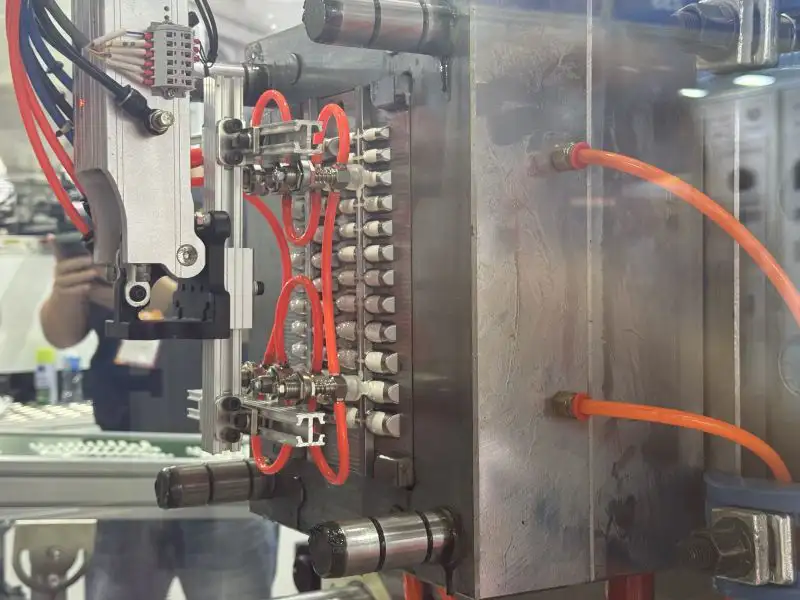

This top-entry robot is the core of modern injection molding automation, engineered for precision, speed, and reliability. Driven by high-performance AC servo motors on all three (XYZ) axes, it delivers exceptional accuracy and smooth, stable motion for complex part handling.

Side-entry Injection Robot (3 / 5 Axis Robot)

Our Side-Entry Robots are custom-engineered for max output in high-speed injection molding. Ideal for thin-wall packaging, medical, and IML applications, they minimize mold-open time for ultra-fast cycle-times. We build both 3-axis models for simple, rapid extraction and advanced 5-axis systems for complex post-mold handling, orientation, and stacking.

People Always ask PlasticMech

Will this robot work with my IMM and factory layout?

This is the most critical question for any plant manager or engineer. A specification mismatch can lead to costly downtime or a solution that simply won’t fit. In this section, we provide the clear, technical data you need to make the right choice.

We will guide you through matching our comprehensive robot series to your specific IMM tonnage and verifying payload capacity for your parts. We also detail all stroke dimensions (Vertical, Crosswise, and Transverse) and address physical constraints, such as offering telescopic arms for low-ceiling factories, ensuring you find the most efficient and perfect fit for your production line.

- IMM Tonnage (Machine Size)

- Small IMMs: Our FA02 Series is ideal for machines from 30T to 120T.

- Medium IMMs: We offer multiple solutions, including the FA05 Series (160T-600T) , FAW05 Series (160T-400T) , and FCW05 Series (200T-500T).

- Large IMMs: Our heavy-duty range includes the FA10 Series (300T-800T) and FAW10 Series (300T-800T).

- Heavy-Duty IMMs: For maximum capacity, our FAW15 (800T-1300T) and FCW25 (1300T-2400T) series are ready.

- Payload (Max Load Capacity)

- Light Parts (2kg): Perfect for the high-speed FA02 Series.

- Common Parts (5kg): Our versatile "05" series (FA05, FAW05, FBW05, FCW05) are all rated for a 5kg max load.

- Heavier Parts (10kg-15kg): Our "10" and "15" series (FA10, FAW10, FCW10, FAW15, FCW15) handle loads from 10kg to 15kg.

- Heavy-Duty Lifting (25kg): The FCW25 Series is built for a robust 25kg payload.

- Speed (Minimum Take-out Time)

- Ultra-High Speed: Our FCW05 Series achieves a min take-out time of just 0.8 seconds , with the FBW05 at 1.0 second.

- High Speed: The FA02 and FAW05 models are also extremely quick, at 1.5 sec and 1.6 sec respectively.

- Standard / Heavy-Duty: Our larger models maintain excellent speeds, typically ranging from 2.0 to 3.5 seconds.

- Stroke & Dimensions (Factory Space)

- Single-Stage Arms (e.g., FA02, FA05): Ideal for factories with ample vertical clearance.

- Telescopic Arms (e.g., FAW, FBW, FCW Series): The dual-stage arm extends and retracts, making it the perfect solution for workshops with low ceilings or height restrictions.

- Wide Range of Travel: Our models cover a vast range of strokes, with Vertical Strokes up to 2500mm and Transverse (horizontal) Strokes up to 4000mm on our largest models.

How Plastic Mech Solves Challenges

My machine is too slow, and mold changeovers kill my productivity.

We know cycle time is money. Our All-Electric series delivers peak performance with injection speeds up to 450 mm/s and response times under 40 ms. Its optimized design cuts dry cycle time by 20% compared to standard machines—meaning more parts per hour and higher output.

My energy bills are out of control.

For customers facing high operational costs, our All-Electric machines deliver up to 80% energy savings over older hydraulics. For those needing hydraulic power, our modern UN Series uses efficient pump technology for an excellent cost-to-performance ratio, balancing power with responsible energy use.

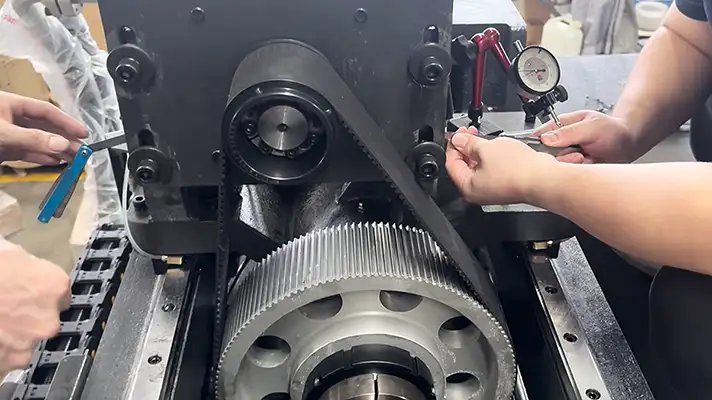

I have high scrap rates because of inconsistent part quality.

In precision molding, inconsistent quality is unacceptable. Our All-Electric machines achieve clamping position repeatability of <0.01 mm and injection motion repeatability of 0.01%. This precision ensures the first part matches the last, slashing scrap and enabling the tightest tolerances.

Unplanned breakdowns and messy hydraulic maintenance are a constant headache.

Built for modern manufacturing, our UN Series Hydraulic IMMs deliver proven 24/7 durability with wear-resistant components that reduce upkeep. For a leak-free, cleanroom-friendly option, our All-Electric series offers lower maintenance and higher Overall Equipment Effectiveness (OEE).

We are losing time and money assembling parts that could be made in one piece.

That’s why we developed our Multi-Component IMMs. Rather than treating assembly as a separate cost, they eliminate secondary processes entirely. By forming a superior chemical and thermal bond in the mold, we boost part quality and cut cycle times by up to 50%—a strategic advantage that streamlines your entire production floor.

Long mold changeover times are one of our biggest sources of lost productivity.

We engineer our machines with Quick Mold Change (QMC) in mind, featuring automated die height adjustment, magnetic or hydraulic mold clamping, and quick-disconnect ejector couplings. Together, these turn a multi-hour manual process into one completed in a fraction of the time—keeping your machine making parts, not waiting for them.

Our services

Comprehensive solutions designed to maximize equipment efficiency, reduce errors, and minimize downtime—covering everything from training and preventive maintenance to rapid parts delivery and secure logistics.

solution

Provide pellet, mold, and robot sources.

Boost efficiency, cut personnel risks.

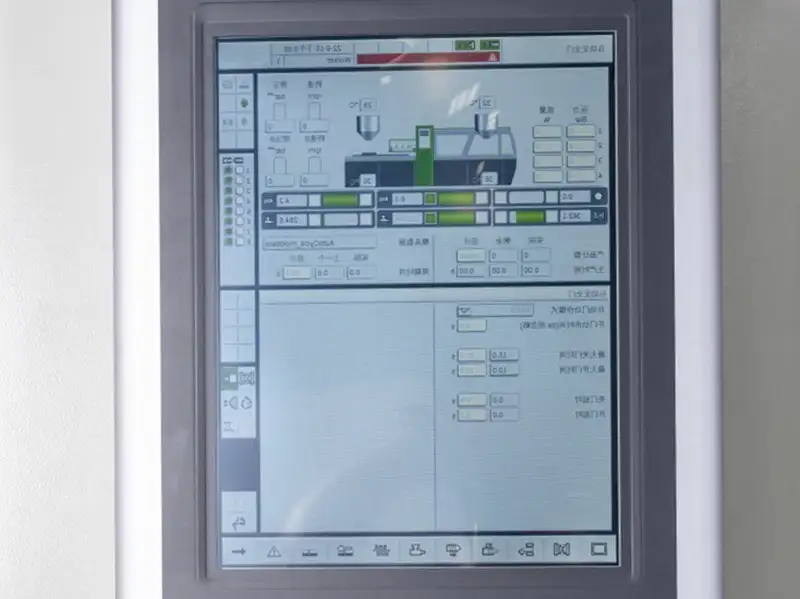

Simple operations

Operator & Maintenance Training.

Empower, reduce errors.

Stable quality

We act as an extension of your team.

High-quality output from the very first shot

Delivery

Supervise delivery process.

Secure machine and notify customer.

Test

Test the machine upon delivery.

Rust-preventive spray and oil after testing

Support

24/7 Remote Diagnostics & Support.

Return to production in minutes, not days

About Plastic Mech

PlasticMech deliver not just machines, but complete, value-driven solutions. With our manufacturing base in Ningbo and commercial office in Hangzhou, we serve a diverse international clientele.

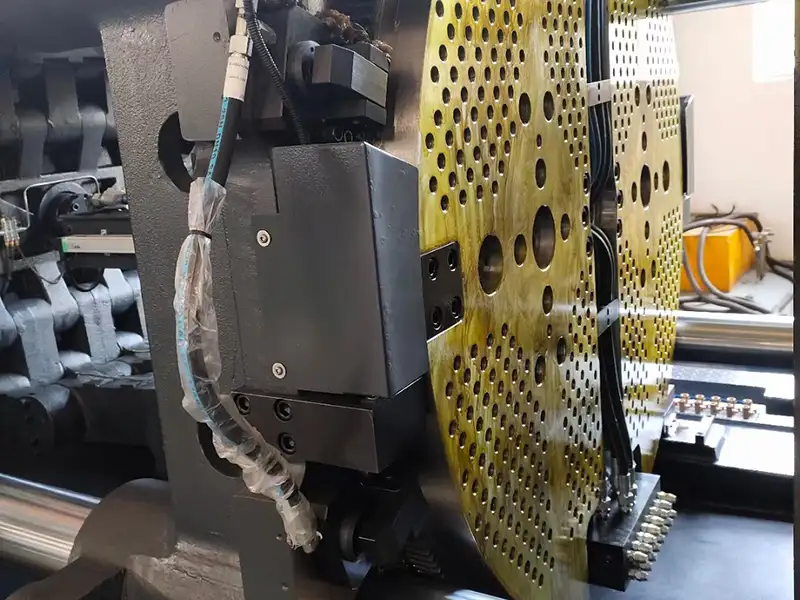

We offer a comprehensive range of injection molding machines—reliable, precise, and energy efficient—with clamping forces from 90t to 6,600t. Our portfolio spans advanced Servo-Hydraulic, space-saving Two-Platen, and high-precision All-Electric series, plus solutions like Multi-Component Molding, In-Mold Labeling (IML), PET preform systems, and more.

Customer Satisfaction Exhibition Site

A dedicated space showcasing real-world applications, success stories, and live demonstrations, allowing customers to experience our solutions’ performance, reliability, and value firsthand.

What Our Happy Clients Say

We have extensive project experience and can tailor injection mold machine solutions to your specific needs, delivering exceptional quality with professional and attentive service.

Professional, enthusiastic and reliable IMM specialists

Common Questions

Most Popular Questions

A technical guide to common questions about 3-axis vs. 5-axis robots, payload calculations, machine compatibility, and achieving faster, more stable cycle times.

To ensure compatibility, you must match four key specifications:

IMM Tonnage: Your machine’s clamping force. Our models are clearly categorized, for example, the FA02 Series is for 30T-120T machines , while the FAW15 Series is for 800T-1300T machines.

Max Load (Payload): This is the total weight of your part plus the gripper (End-of-Arm Tooling). We offer a wide range from light 2kg payloads to heavy-duty 25kg payloads.

Stroke Requirements: You must measure the required Vertical (up/down), Crosswise (in/out of the mold), and Transverse (side-to-side) travel your application needs.

Factory Height: For low ceilings, a Telescopic Arm (dual-stage) is necessary. For standard or high ceilings, a Single-Stage Arm is a robust solution.

The primary differences are the arm type, speed, and suitability, which are all designed for different applications.

FA Series (e.g., FA02, FA05) are our standard Single-Stage (single-arm) robots, offering excellent reliability.

FAW / FBW / FCW Series (e.g., FAW05, FCW10) feature Telescopic (dual-stage) Arms. These are designed to achieve a long vertical stroke while maintaining a low overall height, making them perfect for factories with ceiling restrictions.

Speed: Models also vary in speed. For example, the FCW05 is an ultra-high-speed model with a 0.8-second take-out time , while the FA10 is a heavy-duty model with a 2.5-second take-out time

Our Full Servo Robots are engineered for speed to maximize your productivity.

Cycle Times: We offer a range of speeds, from standard cycles of 2.0-3.0 seconds (like the FAW15 ) to ultra-high-speed cycles as low as 0.8 seconds (FCW05 Series ).

Applications: Our systems are turnkey solutions for all your automation needs, including high-speed part extraction, precise insert placement, in-mold labeling (IML), in-mold decorating (IMD) , degating, stacking, and palletizing.

Yes. While our catalog features standard Top-Entry (Top-entry) models, we are a provider of intelligent turnkey solutions and specialize in custom engineering. We can design and build non-standard systems, including 3-axis and 5-axis Side-Entry Robots, which are ideal for high-volume, thin-wall products (like packaging or medical parts) that require extremely fast cycle times.

We provide comprehensive support for our global users. Our service includes:

Installation: Full on-site installation and integration with your existing IMMs.

Training: We offer complete training for your operators and technicians on how to program the robot, perform routine maintenance, and troubleshoot.

After-Sales Support: All our robots come with a standard warranty. We provide reliable technical support and a stable supply of spare parts to ensure your production line experiences minimal downtime.

Stop Guessing Which Machine to Buy

Ready to Automate Your Production?

Fill out the form below, and one of our specialists will contact you to discuss your application and provide a no-obligation quote.