The evolution from hydraulic to all-electric technology marks a fundamental shift in injection molding. By replacing pumps and valves with high-precision, servo-electric motors, all-electric machines offer a level of process control and energy efficiency that was previously out of reach. This direct-drive system empowers manufacturers to achieve exceptional part repeatability, reduce operational costs, and maintain a cleaner, quieter production environment. This guide explores the mechanics behind this innovative technology and its tangible benefits for modern manufacturing operations.

What is an All-Electric Injection Molding Machine?

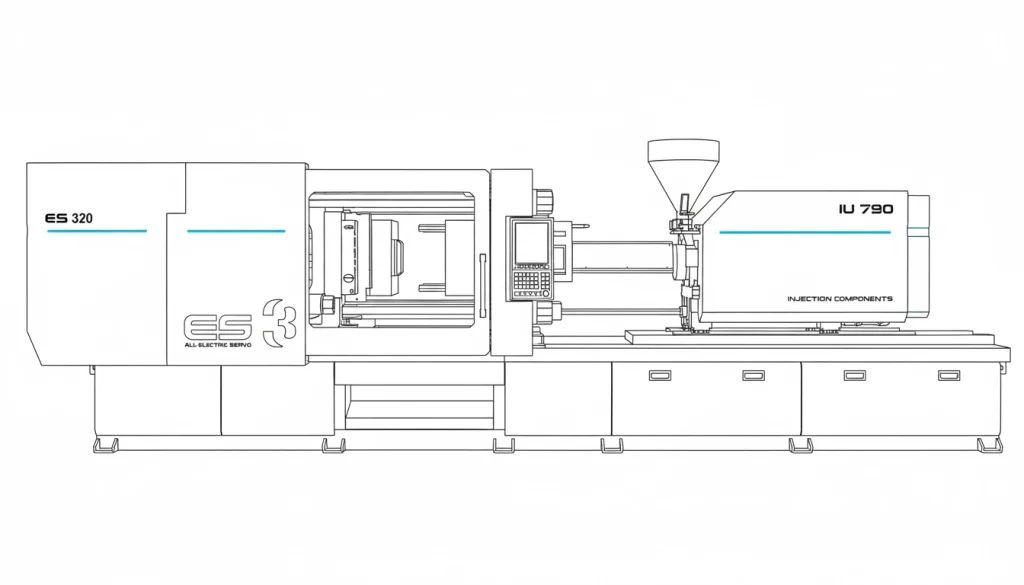

An all-electric injection molding machine fundamentally redefines motion control by replacing a traditional hydraulic system with dedicated, high-performance servo motors. Each major function, including injection, clamping, and ejection, is driven by its own motor. This architecture of independent, direct-drive axes enables digital synchronization and allows for simultaneous machine movements, which can significantly shorten cycle times. Governed by a closed-loop feedback system, the motors execute commands with exceptional precision, eliminating the response lag and pressure variations typical of hydraulic machines.

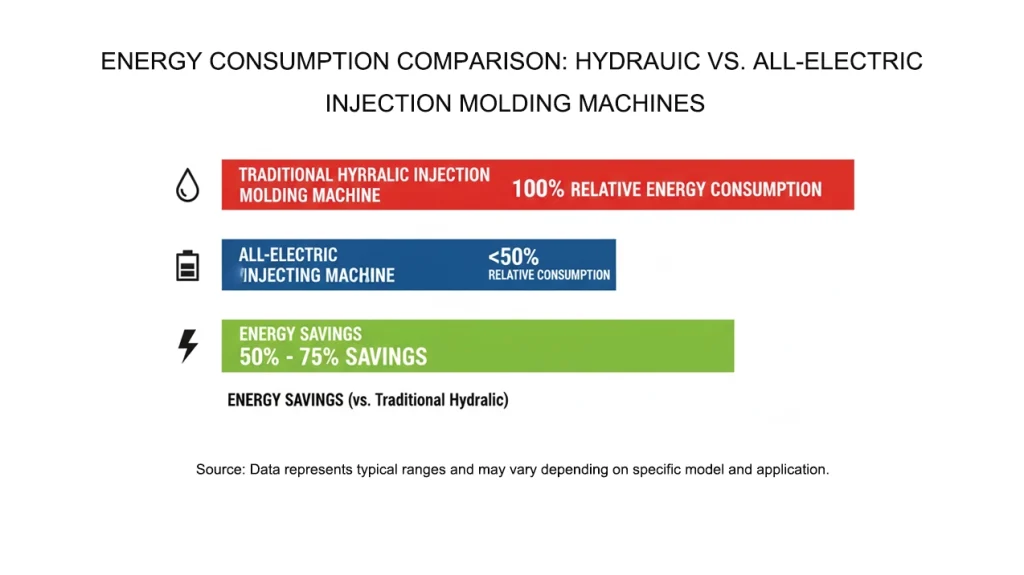

This technological shift delivers two distinct categories of advantages. First, in terms of performance, the digital control ensures unmatched repeatability from shot to shot, leading to higher part quality and lower scrap rates. Second, from an operational standpoint, the “power on demand” nature of servo motors—consuming energy only when active—can reduce electricity consumption by 50-70% over hydraulic counterparts. The elimination of hydraulic oil also results in a cleaner, quieter, and lower-maintenance operation, making all-electric machines the standard for sensitive environments like medical device and electronics manufacturing.

The All-Electric Difference: Benefits and Considerations

All-electric injection molding machines represent a strategic advancement in manufacturing, offering a compelling blend of precision, efficiency, and sustainability. While the technology presents specific trade-offs, a clear understanding of its benefits and challenges is key to a sound investment.

Key Advantages

- Energy Efficiency: A 30-70% reduction in power consumption.

- Superior Precision: Exact control of position, speed, and pressure.

- Faster Cycle Times: Simultaneous machine movements reduce cycle times.

- Cleaner Operation: No hydraulic oil means zero risk of contamination.

- Reduced Noise Levels: Typically 5-10 dB quieter than hydraulic machines.

- Lower Cooling Requirements: Less heat generation during operation.

- Consistent Part Quality: Shot-to-shot repeatability within tight tolerances.

- Lower Maintenance Costs: Fewer components subject to wear and tear.

Challenges

- Higher Initial Investment: 15-30% more expensive than hydraulic machines.

- More Complex Repairs: Requires specialized technicians for servicing.

- Tonnage Limitations: Less common in ultra-high tonnage applications.

- Cooling Requirements for Motors: Servo motors need dedicated cooling systems.

- Sensitivity to Power Quality: Voltage fluctuations can affect performance.

The core value of all-electric machines lies in their exceptional precision and efficiency, which directly translates to cost savings and higher quality output. Their “power-on-demand” operation leads to a remarkable 30-70% reduction in energy consumption and lower maintenance costs. However, the primary challenge is the higher initial investment, which can be 15-30% greater than hydraulic alternatives. This cost difference is often offset by operational savings, with the return on investment frequently realized within 2-5 years. Ultimately, the decision to adopt this technology is a strategic one that balances these upfront costs against significant long-term benefits.

Applications and Suitability

All-electric injection molding machines excel in applications where precision, cleanliness, and energy efficiency are paramount. Their advanced capabilities have made them the standard for a variety of demanding industries.

Based on your request, here are the three points from your original text, separated as distinct sections. The content has been maintained without additions, and each section adheres to the character limit you specified.

Medical Industry

Clean room compatibility and contamination-free operation make these machines ideal for medical components, implants, and diagnostic devices where eliminating contamination risks is essential.

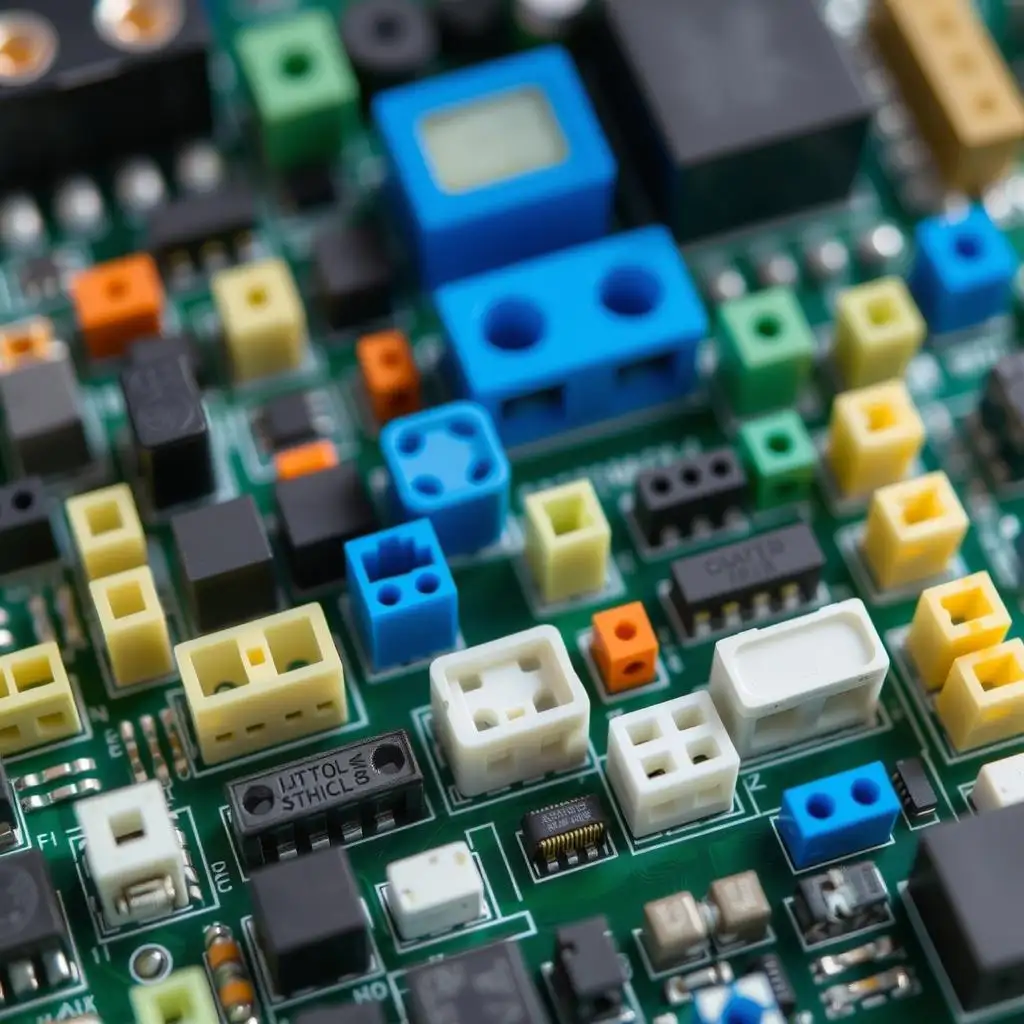

Electronics Manufacturing

The production of connectors, housings, and precision electronic components benefits from the tight tolerances and consistency provided by all-electric machines.

Automotive Sector

These machines are crucial for manufacturing a wide range of precision parts, from interior components to critical under-hood applications, delivering the reliability and high-speed repeatability required in this sector.

Advanced Material Processing The precise control of all-electric machines also makes them ideal for processing high-performance engineering resins that require exact processing conditions. This includes materials like:

- Polycarbonate (PC)

- Polyamide (PA/Nylon)

- Polyoxymethylene (POM/Acetal)

- Liquid Silicone Rubber (LSR)

- Thermoplastic Elastomers (TPE)

Explore Industry-Specific Applications

Learn how all-electric injection molding machines are used in your specific industry with our detailed application guides.

Prominent Brands in All-Electric Injection Molding Machines

The all-electric injection molding machine market is defined by several global leaders, each with unique strengths and specializations that cater to different manufacturing needs.

| Brand | Key Strengths | Notable Series |

| Engel | High precision, energy efficiency, tie-bar-less options | e-motion, e-mac |

| Arburg | German engineering, versatility | Allrounder A |

| Fanuc | Reliability, longevity, precision control | Roboshot α-SiA |

| Sumitomo (SHI) Demag | Speed, precision, zero-defect production | IntElect |

| Shibaura Machine | Wide tonnage range, advanced controls | EC-SXIII |

| Nissei | Compact design, energy efficiency | NEX |

Beyond the machine specifications, the true value of your investment hinges on crucial support factors. When considering a brand, evaluate the availability of local service, accessibility of spare parts, and the quality of technical support. These elements significantly impact a machine’s long-term uptime and your total cost of ownership.

Is an All-Electric Machine Right for Your Production Needs?

Determining the right technology for your operation requires a careful evaluation of your specific requirements against the capabilities of all-electric machines. The answer hinges on a balance between upfront investment and long-term operational benefits. By weighing both the advantages and challenges, you can make an informed decision by considering the following key factors.

Production Volume and ROI: All-electric machines offer a significant advantage in operations requiring rapid cycles and high production volumes. Their faster, simultaneous movements directly contribute to higher throughput. In regions with high energy costs, the substantial power savings can quickly justify the higher initial investment, leading to a faster return on investment.

Part Precision and Quality: For components with complex geometries, tight tolerances, or strict quality standards, the superior precision of all-electric machines is crucial. Their exact control over process parameters can significantly reduce scrap rates and ensure unmatched shot-to-shot consistency, guaranteeing part quality that hydraulic systems often cannot match.

Cleanliness and Application Sensitivity: If your production environment is a clean room or if your product is sensitive to contamination, the oil-free operation of an all-electric machine is a decisive advantage. The elimination of hydraulic fluid removes all risk of leaks, making them ideal for medical, food, and electronics applications.

Flexibility and Future-Proofing: Beyond a single application, consider your long-term needs. The versatility and quick mold change capabilities of all-electric machines allow for greater production flexibility. Their advanced digital controls make it easier to adapt to new materials and complex processes, positioning your operation to meet future market demands.

Get a Personalized Assessment

Not sure if all-electric technology is right for your specific production needs? Our experts can provide a detailed assessment based on your unique requirements.

How We Can Help

Navigating the transition to all-electric injection molding technology can be a complex challenge. Our expertise simplifies the process, providing a seamless partnership from initial assessment to long-term success.

Strategic Consultation & Machine Selection

We provide objective, data-driven insights to assess your needs, guiding you to select the optimal machine that aligns with your specific production goals and budget.

Seamless Implementation & Operator Training

We manage installation and provide hands-on training, ensuring a smooth transition and a rapid ramp-up to full production with minimal downtime.

Comprehensive After-Sales Support

Our comprehensive support extends beyond the sale with preventive maintenance programs, expert troubleshooting, and optimization services to maximize your return on investment.

Our goal is not just to supply machinery, but to be a strategic partner committed to your long-term efficiency and profitability. We provide the practical solutions you need to overcome challenges and achieve your operational goals.

Start Your Transition to All-Electric Technology

Ready to explore how all-electric injection molding machines can transform your manufacturing operation? Schedule a consultation with our experts today.

Summary

The shift to all-electric injection molding technology is more than an evolution; it is a strategic investment that delivers tangible, long-term returns. While requiring a higher initial investment, all-electric machines deliver unmatched precision, superior energy efficiency, and a cleaner operational environment, offering a rapid return on investment and a lower total cost of ownership. As global trends demand greater sustainability, rising energy costs, and more stringent quality control, these advanced machines are becoming the new industry standard. Ultimately, adopting this technology is a forward-thinking decision that enables manufacturers to enhance their competitiveness, sustainability, and profitability in a demanding market.

Take the Next Step

Contact our team today to discuss how all-electric injection molding machines can benefit your specific manufacturing operation.