The injection molding landscape has evolved significantly, progressing from foundational hydraulic systems to highly precise all-electric alternatives. Today, the industry is advancing with the adoption of hybrid injection molding machines. These systems represent a pivotal development, intelligently blending the high-force capabilities of hydraulics with the meticulous control of electric drives to meet modern manufacturing demands.

Driven by the need for greater energy efficiency and higher production standards, hybrid machines offer a robust solution. They address the inherent limitations of their predecessors by providing the powerful clamping force required for large parts while delivering the superior energy savings and repeatability characteristic of all-electric models. This synergy reduces energy consumption and operational noise and enables the production of complex, high-quality components with shorter cycle times, empowering manufacturers to build a more sustainable and cost-effective future.

What is a Hybrid Injection Molding Machine?

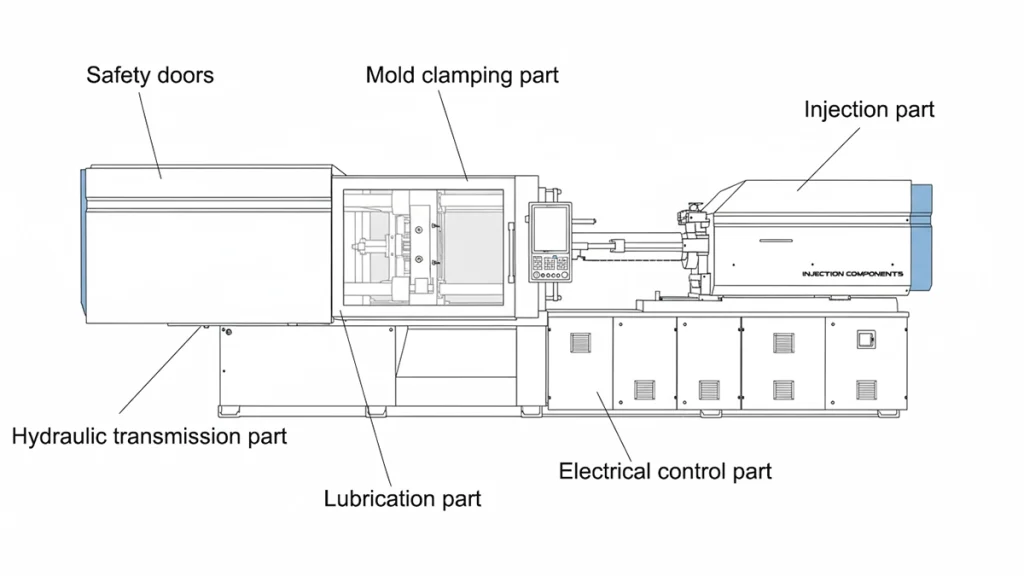

A hybrid injection molding machine integrates the best of hydraulic and electric technologies into a single, cohesive system. While purely hydraulic machines rely on fluid power and all-electric machines use servo motors exclusively, hybrid machines strategically leverage each technology for specific tasks.

Typically, electric servo motors power the precise and rapid movements, such as injection, screw rotation for plasticizing, and part ejection. Meanwhile, the robust hydraulic system is reserved for high-force functions like mold clamping and pressure holding. This intelligent division of labor results in a machine that delivers superior energy efficiency, faster cycle times, and enhanced repeatability. By combining the high-force capabilities of hydraulics with the precision and speed of electric drives, hybrid machines provide a powerful solution for a wide range of molding applications.

How Hybrid Machines Achieve the Best of Both Worlds

The sophisticated engineering of hybrid injection molding machines allows them to overcome the limitations of single-technology systems by assigning hydraulic and electric components to their most suitable functions.

Electric Components and Their Functions

In a hybrid system, electric servo motors manage the precise, high-speed movements critical to part quality and cycle efficiency. These components are responsible for:

- Injection and Plasticizing: Providing fine-tuned control over screw speed, position, and back pressure to ensure a uniform melt quality, which is essential for the final product’s integrity.

- Ejection Mechanisms: Offering highly controlled and programmable part removal to prevent damage, especially with delicate or complex parts.

- Auxiliary Movements: Managing functions like core pulls and mold plate positioning required for intricate geometries.

Hydraulic Elements and Their Roles

The hydraulic system is leveraged for its unparalleled ability to generate and sustain high force. It typically handles the most demanding operations:

- Mold Clamping: Generating the immense clamping forces—often ranging from 90 to over 2800 tons—required to keep the mold securely closed against injection pressure.

- Holding Pressure: Maintaining consistent pressure during the cooling phase to ensure part density and dimensional stability.

- Other Heavy-Duty Movements: Managing any large-scale machine actions that require substantial, sustained force.

Advanced Integration and Control

The core of a hybrid machine is its advanced control system that orchestrates both technologies. These intelligent controls:

- Optimize Energy Usage: Activate the hydraulic pump only when high force is required (e.g., during clamping), dramatically reducing energy consumption during other phases of the cycle.

- Enable Real-time Adjustments: Facilitate quick, responsive changes to production parameters, leading to higher repeatability and fewer defects.

- Support Data Collection: Enable comprehensive data logging for process optimization, quality assurance, and traceability—a key requirement in modern manufacturing.

This seamless integration of hydraulic power with electric precision allows hybrid machines to deliver the optimal balance of efficiency, speed, and force, a direct benefit to any operation focused on high-quality, high-performance production.

The Competitive Edge: Key Advantages of Hybrid Technology

By combining hydraulic power and electric precision, hybrid injection molding machines deliver significant operational advantages that provide manufacturers with a competitive edge. This integrated approach reduces operational costs, enhances production flexibility, and meets the growing demand for high-quality, complex components.

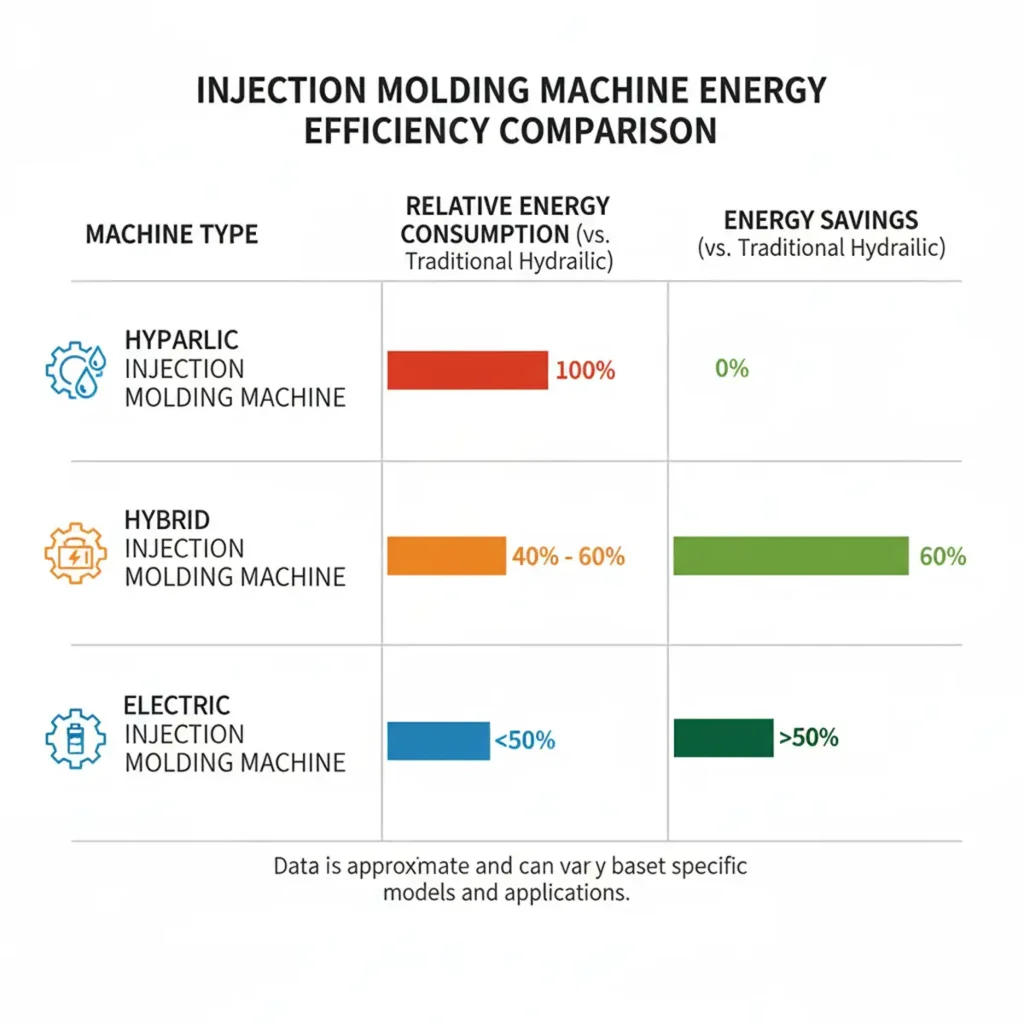

Energy Efficiency

Hybrid systems typically consume 20-60% less energy than conventional hydraulic machines. Electric components draw power only when in motion, and variable-speed hydraulic pumps adjust their output to match real-time demand instead of running continuously. This results in substantial reductions in electricity costs and a more sustainable operation.

Precision and Repeatability

The electric servo-driven components provide exceptional control during critical phases like injection and metering. This leads to more consistent part quality, dramatically reduced scrap rates, and the ability to manufacture complex, thin-walled components with extremely tight tolerances. For manufacturers, this translates directly to higher yields and better material utilization.

Reduced Maintenance and Increased Uptime

By reserving the hydraulic system for high-force functions, hybrid machines experience less wear on components, reduced oil degradation, and fewer leaks. This combination leads to higher uptime and lower long-term service costs, ensuring more reliable production schedules.

Cleaner and Quieter Operation

With reduced hydraulic oil requirements and improved containment systems, hybrid machines foster a cleaner manufacturing environment. They also operate with significantly less noise. This is a critical advantage for facilities in regulated industries such as medical device manufacturing and food packaging, where cleanliness is paramount.

Ready to Boost Your Manufacturing Efficiency?

Our team of experts can help you determine if a hybrid injection molding machine is the right solution for your specific production needs.

Head-to-Head Comparison: Hybrid vs. Hydraulic vs. All-Electric

For manufacturers and material suppliers, choosing the right machine is a critical decision that impacts everything from production quality to operational costs. This head-to-head comparison highlights the key differences between the three primary injection molding technologies, providing a clear guide for making an informed choice.

| Performance Metric | Hydraulic | All-Electric | Hybrid |

| Energy Efficiency | Low – Continuous pump operation | Excellent – Up to 70% energy savings | Very Good – 20-60% energy savings |

| Precision & Repeatability | Moderate | Highest – Superior accuracy in injection and metering | Very Good |

| Clamping Force | Excellent (90-2800+ tons) | Limited (typically up to 500 tons) | Excellent (90-2800+ tons) |

| Cycle Speed | Moderate | Fastest | Fast |

| Noise Level | High | Lowest | Moderate |

| Maintenance | High – Frequent oil changes & filter replacements | Lowest – Minimal component wear | Moderate – Reduced hydraulic system demands |

| Initial Investment | Lowest | Highest | Moderate to High |

| Cleanliness | Poor – Risk of oil leaks | Excellent – No hydraulic oil | Good – Minimal oil use & better containment |

When to Choose a Hybrid Machine

- High Force & Precision: For applications demanding both powerful clamping and accurate injection, such as automotive components or large housings.

- Cost-Effective Efficiency: When energy savings are a priority, but the capital cost of an all-electric machine is prohibitive.

- Modernization: As an ideal and balanced upgrade from older, less efficient hydraulic systems.

- Diverse Production: For facilities manufacturing a mix of large and small, intricate parts on the same equipment.

When to Consider Alternatives

- Ultra-Cleanliness: An all-electric machine is the superior choice for certified cleanroom environments.

- Strict Budget Constraints: A hydraulic machine offers the lowest initial investment for operations with severe budget limitations.

- Extreme Precision: An all-electric machine excels in specialized applications like micro-molding.

Key Industries and Applications: Where Do Hybrids Shine?

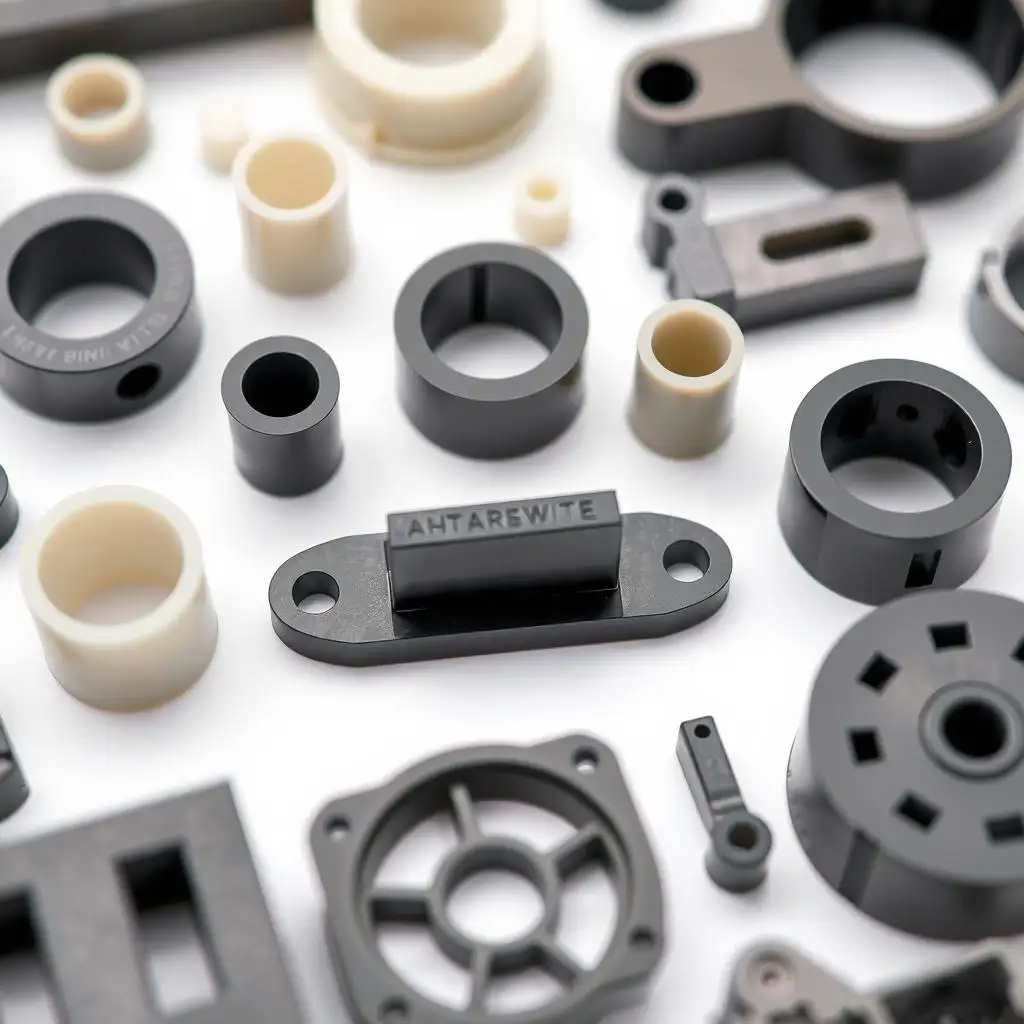

The versatility and performance of hybrid injection molding machines make them ideal for a wide range of industries. Their unique combination of power and precision provides a decisive advantage in sectors where quality, efficiency, and material integrity are paramount.

Automotive

The automotive industry relies on hybrid machines to meet strict demands for vehicle performance, safety, and weight reduction. These machines are particularly effective for molding:

- Lightweight structural components requiring high strength and precision.

- Large interior panels with complex geometries and premium surface finishes.

- Under-hood components that must withstand extreme thermal and chemical conditions.

- Thin-walled parts designed to reduce vehicle weight while maintaining structural integrity.

The ability to produce large, complex parts with tight tolerances and excellent surface finishes makes hybrid machines a cornerstone of modern automotive manufacturing, directly contributing to fuel efficiency and safety.

Medical

In the highly regulated medical sector, hybrid machines offer the precision and cleanliness needed for critical applications. They are used for:

- Diagnostic equipment housings with precise fitting requirements.

- Surgical instruments that combine durability with intricate features.

- Drug delivery devices requiring consistent quality and sterile production.

- Implantable components with strict material and tolerance specifications.

Medical manufacturers value hybrid machines for their cleaner operation—a crucial factor for regulated environments—while maintaining the exceptional precision needed for high-value components.

Consumer Goods

The consumer goods sector leverages hybrid technology to balance high-volume production with consistent quality and cost-effectiveness. Key applications include:

- Electronic device housings with complex internal structures.

- High-volume packaging components requiring consistent quality and rapid cycle times.

- Household appliance parts that combine aesthetic appeal with reliable functionality.

- Toys and recreational products with detailed features and strict safety requirements.

By offering a blend of speed and precision, hybrid machines empower the consumer goods industry to meet the dual demands for high throughput and superior product quality.

Specialized in Your Industry?

Our application engineers can provide industry-specific insights on how hybrid injection machines can optimize your particular manufacturing processes.

Is a Hybrid Machine the Right Choice for Your Application?

A hybrid injection molding machine represents a significant investment, and its selection is a strategic decision that directly impacts a company’s productivity and profitability. The choice between hybrid, hydraulic, and all-electric systems hinges on a careful evaluation of a business’s unique operational needs, production environment, and long-term financial goals. Therefore, a data-driven approach is essential to ensure the chosen technology aligns with your manufacturing and business objectives.

Key Factors to Consider

Production Volume and Cycle Time

Hybrid machines are well-suited for medium- to high-volume production. Their electric-driven movements reduce cycle times, boosting overall output for continuous, high-throughput manufacturing.

Part Size and Complexity

Hybrids offer unmatched versatility for producing a diverse portfolio of products—from large parts needing high clamping force to complex components requiring superior accuracy.

Energy Costs and Sustainability Goals

For companies with high energy costs or corporate sustainability initiatives, the 20-60% energy savings over hydraulic machines present a compelling financial and environmental benefit.

Material Properties and Quality Control

The enhanced control and repeatability of hybrid machines make them an excellent choice for molding with high-performance engineering plastics. Precise management of injection parameters ensures consistent melt quality, which reduces material waste and guarantees a high-quality finished product.

Decision Support:To make a data-driven choice, consider using simulation tools offered by equipment suppliers. These analyses can model your specific production requirements, taking into account part specifications, material types, and energy costs to provide a detailed, data-backed recommendation for the best machine technology for your business.

Cost-Benefit Analysis: Understanding the Total Cost of Ownership (TCO)

When considering a major capital expenditure, looking beyond the initial purchase price is crucial. Evaluating a machine based on its Total Cost of Ownership (TCO) provides a more accurate and comprehensive picture of its long-term financial value.

Initial Investment

Hybrid machines typically represent a middle ground in terms of capital expenditure. They are generally priced 10-25% higher than comparable hydraulic machines but remain 15-30% less expensive than all-electric alternatives with similar specifications.

Operational Costs

The financial benefits of a hybrid machine are most evident in its operational savings. Significant energy efficiency—driven by on-demand power usage—translates to substantial reductions in electricity bills. Furthermore, reduced maintenance requirements and a longer component lifespan lead to lower long-term service costs compared to hydraulic systems.

Production Benefits

Hybrid machines deliver bottom-line improvements through enhanced production efficiency. Reduced scrap rates, improved cycle times, and consistently high part quality all contribute to a better yield. This is particularly valuable for high-volume operations and for molding expensive, complex components, as it directly reduces material waste and maximizes profitability.

Sample ROI Calculation Framework

| Cost/Benefit Factor | Calculation Method | Typical Values |

| Energy Savings | (kWh saved per hour × annual operating hours × electricity cost per kWh) | $5,000-$25,000 annually |

| Maintenance Reduction | (Hydraulic machine annual maintenance – Hybrid machine annual maintenance) | $2,000-$8,000 annually |

| Material Savings | (Scrap reduction % × annual production volume × material cost per unit) | Varies significantly by part value & volume |

| Cycle Time Improvement | (Time saved per cycle × annual cycles × hourly operational cost) | 5-15% improvement over hydraulic machines |

| Additional Investment | (Hybrid machine cost – Hydraulic machine cost) | $30,000-$150,000 depending on machine size |

“The typical ROI period for upgrading to a hybrid injection molding machine ranges from 2 to 4 years, depending on production volume, energy costs, and the specific application. For high-volume operations, this payback period can be even shorter.”

Integration with Industry 4.0 and Automation

Beyond their mechanical advantages, modern hybrid injection molding machines are built as a core component of the smart factory. They are designed with full Industry 4.0 capabilities, enabling seamless integration with automation systems and data-driven manufacturing practices.

Smart Manufacturing Features

These intelligent machines are equipped with advanced features that empower manufacturers with unparalleled process control and insight:

- Real-time Monitoring: Sensors provide live data on every aspect of the molding process.

- Process Optimization: Sophisticated control systems make automatic, real-time adjustments to maintain part quality.

- Data-Driven Decisions: Comprehensive data collection and analysis enable continuous process improvement and quality control.

- Proactive Maintenance: Remote monitoring and diagnostics help predict and prevent machine issues, maximizing uptime.

Automation Integration

Hybrid machines are engineered for a fully automated production environment, featuring:

- Robotic Compatibility: Standardized interfaces for seamless integration with robotic end-of-arm tooling and part handling systems.

- Peripheral Coordination: Centralized control and communication with conveyor systems, mold temperature controllers, and quality inspection equipment.

- MES Integration: The ability to communicate with central Manufacturing Execution Systems for holistic production management.

- Lights-Out Production: Support for fully automated, unmanned manufacturing scenarios, enhancing efficiency and flexibility.

Connectivity and Data for the Supply Chain:Modern hybrid machines support OPC UA (Open Platform Communications Unified Architecture), the industry standard for secure machine-to-machine communication. This connectivity doesn’t just benefit the manufacturer—it creates opportunities for closer collaboration with suppliers. For plastic material distributors, this data can enable better forecasting, improved traceability, and a deeper understanding of material performance under real-world conditions.

Conclusion: Partnering for Future-Proof Manufacturing

Hybrid injection molding machines represent a pivotal advancement in plastic manufacturing. They offer an optimal and balanced approach, delivering the energy efficiency, precision, and versatility needed to meet today’s demanding production standards. This technology is more than just a middle ground between hydraulic and all-electric systems; it’s a strategic investment in a more productive and sustainable future.

As the industry embraces a new era of smart manufacturing, the integration capabilities of hybrid machines with Industry 4.0 systems become a key competitive differentiator. Their ability to provide data-driven insights and enable continuous improvement makes them a future-proof solution ready for the challenges of tomorrow.

Ultimately, achieving a successful manufacturing operation hinges on a synergistic relationship between the right technology and the right materials. Hybrid machines provide the ideal platform for molding with high-performance and innovative plastic granules. When evaluating your next investment, consider not only the machine’s total cost of ownership but also how its capabilities can maximize the value and quality of your materials. By choosing the right combination of machinery and granules, you can unlock a new level of efficiency and quality.

Ready to Maximize Your Investment?

Hybrid machines can boost your profitability. Contact us today to learn how this technology can optimize your production.