Your Partner in Injection Molding Solutions Since 2010

About Plastic Mech

Welcome to Plastic Mech, a specialized manufacturer of high-performance horizontal injection molding machines. Since our founding in late 2010, we have been dedicated to providing manufacturers worldwide with reliable, efficient, and precise solutions. Our comprehensive portfolio includes all-electric, hydraulic, and hybrid injection moulding machines, designed to meet the diverse needs of modern industry.

Over the past decade, we have grown from a promising start-up into a trusted industry player, marked by the establishment of our two dedicated R&D centers in Hangzhou and Ningbo. This journey of continuous improvement and customer focus has enabled us to serve clients across various sectors, helping them achieve their production goals.

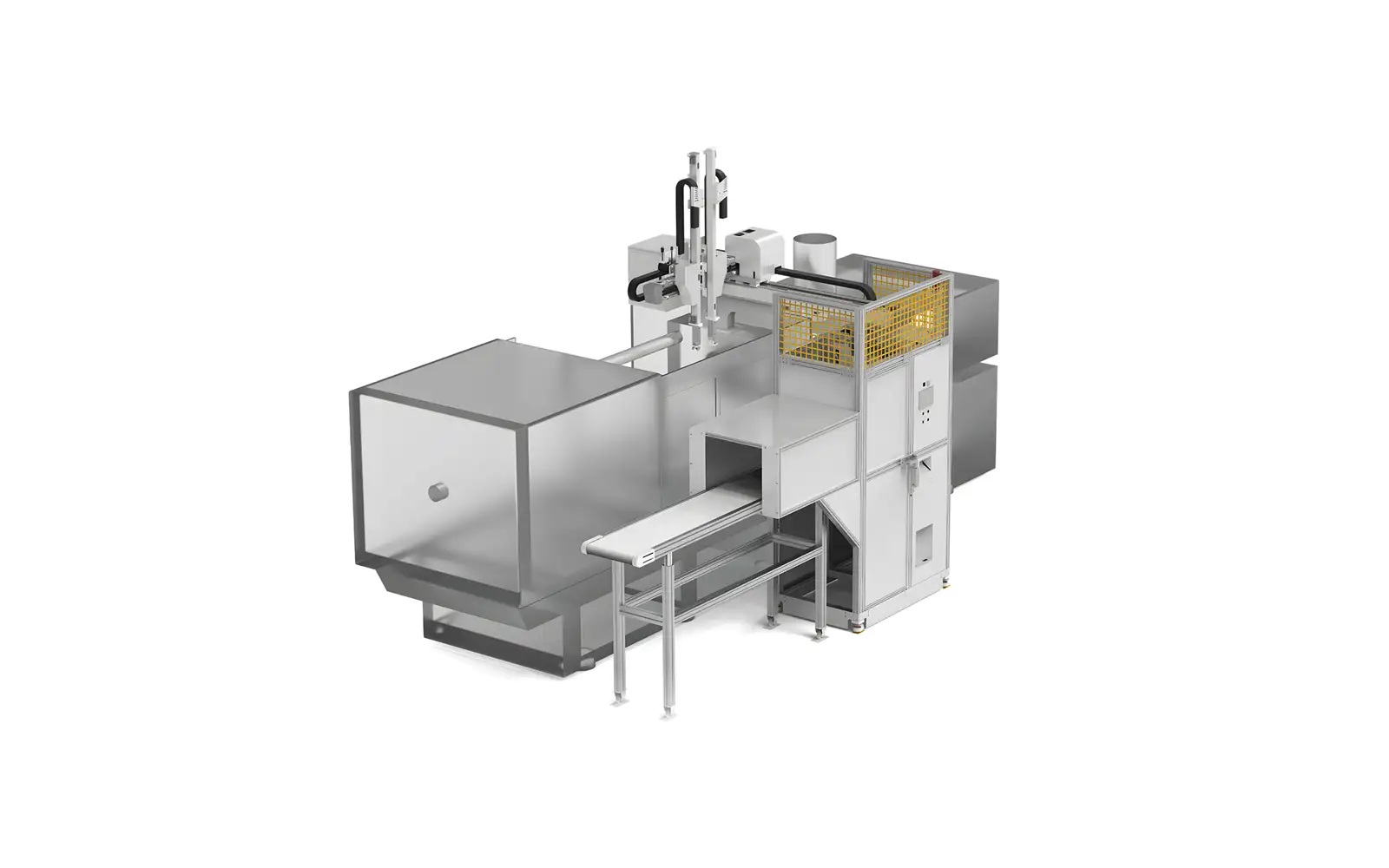

A Look Inside Our Production Hub

Pictured here is our state-of-the-art manufacturing facility in Hangzhou, a cornerstone of our production capabilities. This plant, alongside our specialized facility in Ningbo, forms our powerful manufacturing network. The Hangzhou hub is dedicated to the core assembly and innovation of our horizontal injection molding machines, leveraging the region’s top-tier technical talent and robust supply chain to create products of exceptional quality and reliability for our global partners.

Our Injection Molding Machine

We specialize in providing a versatile range of horizontal injection molding machines tailored to your specific application needs.

All-Electric Injection Molding Machines:

Ideal for high-precision applications, our all-electric machines offer unparalleled accuracy, repeatability, and energy efficiency. They are the perfect choice for medical, electronics, and optical components manufacturing, ensuring a clean and quiet operation.Hydraulic Injection Molding Machines:

Known for their robust power and cost-effectiveness, our hydraulic machines are workhorses designed for durability and high clamping force. They excel in producing large automotive parts, containers, and general-purpose goods.Hybrid Injection Molding Machines:

Combining the best of both worlds, our hybrid models deliver the precision and energy savings of electric technology with the powerful clamping force of hydraulics. This versatility makes them an excellent all-around solution for complex and demanding production tasks.

Advanced Robotic Arms for Injection Molding

We are driven by our mission: “Striving for Excellence, Achieving High Efficiency”. We extend this philosophy to your production floor with our sophisticated line of robotic arms, designed to seamlessly integrate with and enhance your injection molding operations. Our solutions transform your process, boosting productivity, precision, and overall profitability.

Complete Automation Solutions: Our robots manage every step, including part take-out, cavity separation, precise arrangement, and boxing. We also offer advanced systems for petri dish assembly, stacking, and automated bagging and sealing.

Advanced In-Mold Labeling (IML): We specialize in both Side-entry and Top-entry IML systems. These are engineered for versatility, handling products from yogurt and milk tea cups to large buckets and lids. Features like modular label magazines and strong vacuum suction ensure flawless application.

High-Speed Performance: Designed to maximize your output, our systems are built for speed. Our PET Preform machine, for example, uses a three-station water cooling device to rapidly increase production rates.

Precision and Quality: Guarantee the quality of your finished products. Our IML systems feature special label separation mechanisms and high-response electrostatic devices (as fast as 0.1s) to ensure a high yield rate.

Flexible and Efficient Design: Adapt to market demands with ease. Our robots feature modular components and are designed for quick product changeovers, saving valuable production time. Many of our designs are also optimized for higher cost performance and saving space.

Our Service

Solution Design & Customization

We don't just sell machines; we design and build customized, integrated solutions—including robotics and automation—that are perfectly tailored to your unique production goals.

Lifecycle Support

From commissioning and training to maintenance and upgrades, our lifecycle support ensures your equipment delivers peak performance and maximum return on investment for years to come.

Productivity & Optimization Services

We help you continuously improve your manufacturing process. Our experts offer services in cycle time optimization, energy saving, and automation upgrades to keep you ahead of the competition.

Sales Market

Russia

Europe

Middle Asia

Middle East

Mexico

Southeast Asia

Latin

Africa

South Africa

Global Market 50+ exporting countries and regions

Serving a Global Market: With a presence in over 50 countries and regions, we have the proven experience to meet international standards and deliver reliable solutions to partners worldwide.

Get a Free Quote

Ready to enhance your production capabilities? Contact our expert team today to discuss your project requirements.

Get in touch

Address

No.2 Building, Huitou industrial Park, Qiuga Town, Yinzhou District Ningbo, China

Email

Jerry@plasticmech.com

Phone

+86-18667388970

Instant Messaging