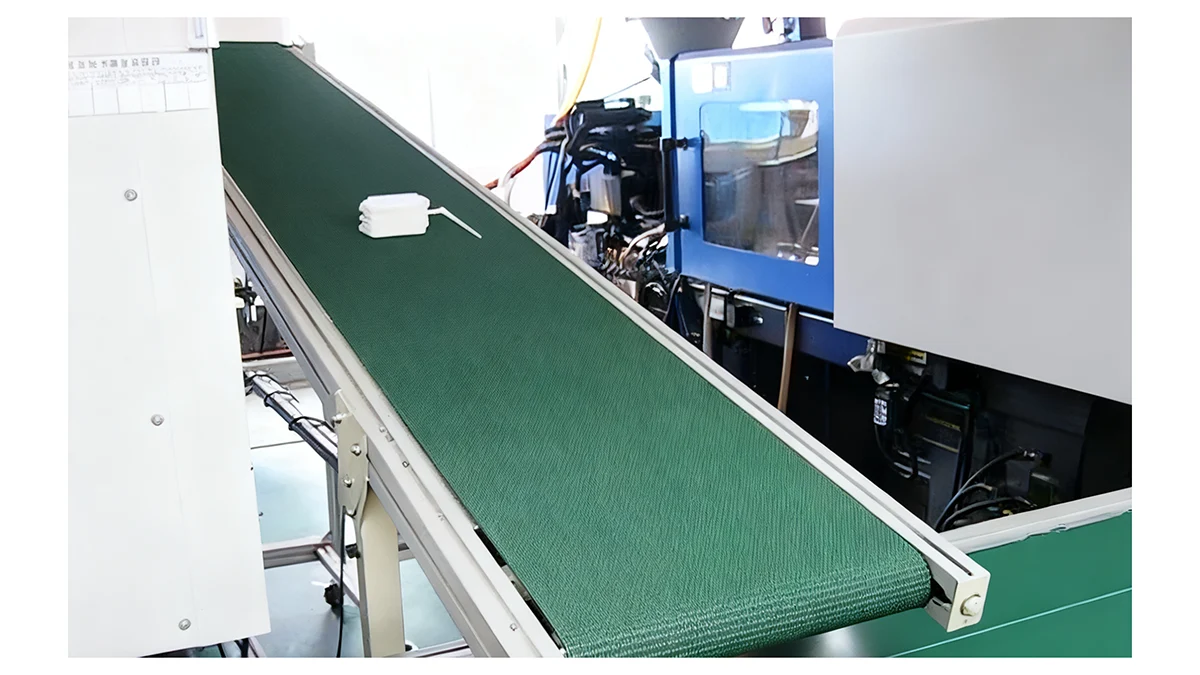

Injection molding is a high-precision manufacturing process where molten plastic is injected into molds to create parts ranging from automotive components to consumer goods. Conveyor belts serve as the backbone for material handling in this environment, transporting freshly molded parts away from the machine for cooling, inspection, assembly, or packaging. They ensure seamless workflow, minimize manual intervention, and help maintain consistent output rates.

In this article, we’ll shift focus from elements like the plasticating unit and clamp tonnage to examine the role of conveyor belts in injection molding operations, including their impact on part handling and overall process reliability.

Types and Classifications of Conveyor Belts

Within an injection molding facility, the conveyor belt acts as the critical link between molding and downstream operations. Its specification is generally guided by three core considerations: the material of the belt, its physical design, and its specific function, all of which must align with the characteristics of the molded parts and the flow of the production line.

1. Material Composition: Balancing Durability and Application Needs

The operating environment dictates the choice of belt material.

- PVC (Polyvinyl Chloride): Serves as a versatile and economical option for general-purpose transportation where extreme conditions are not a factor.

- PU (Polyurethane): Offers enhanced resistance to oils, greases, and various cleaning chemicals. Its flexibility contributes to stable tracking, and its compliance with food-grade standards makes it applicable for medical and consumer product molding.

- Silicone: Essential for handling components ejected at high temperatures, where thermal stability is paramount.

- Rubber & Polyester: Typically employed in heavy-duty scenarios or where specific frictional properties are required to prevent part movement.

2. Structural Design: Defining the Method of Transport

The belt’s architecture determines how a part is conveyed and handled.

- Flat Belts: Provide a consistent, stable surface suitable for the majority of standard parts.

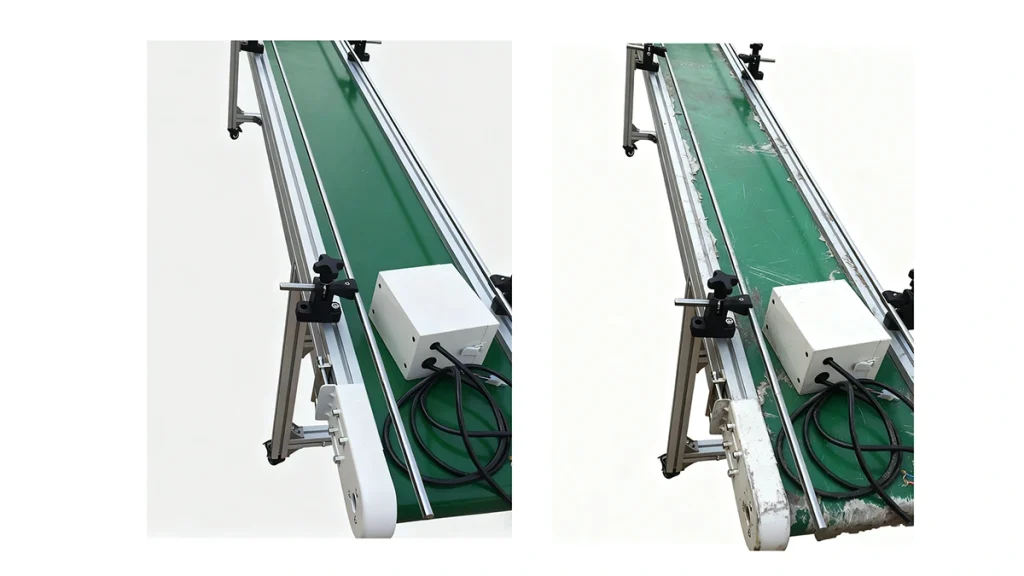

- Cleated Belts: Incorporate raised sections to securely contain parts and prevent rollback on inclined or declined sections of the line.

- Modular Belts: Constructed from interlocking plastic segments, this design supports complex layout paths, simplifies cleaning procedures, and allows for the quick replacement of individual sections, minimizing downtime.

- Roller Bed Conveyors: Utilize a bed of rollers to support the belt, significantly reducing friction for heavier loads and improving energy efficiency.

3. Functional Specialization: Addressing Specific Line Requirements

Some belts are defined by a dedicated operational capability that solves a particular challenge.

- Accumulation Belts: Permit parts to gather at a controlled density, creating a buffer that decouples the molding machine from downstream processes and prevents line stoppages.

- Magnetic Belts: Employ an embedded magnetic field to securely hold and transport parts with ferrous metal inserts, ensuring precise positioning for subsequent assembly or packaging steps.

The interplay of these factors determines the final solution. For example, production lines requiring frequent layout changes or stringent hygiene protocols often benefit from the customization and ease of maintenance inherent to modular belt designs.

Applications in Injection Molding Industry

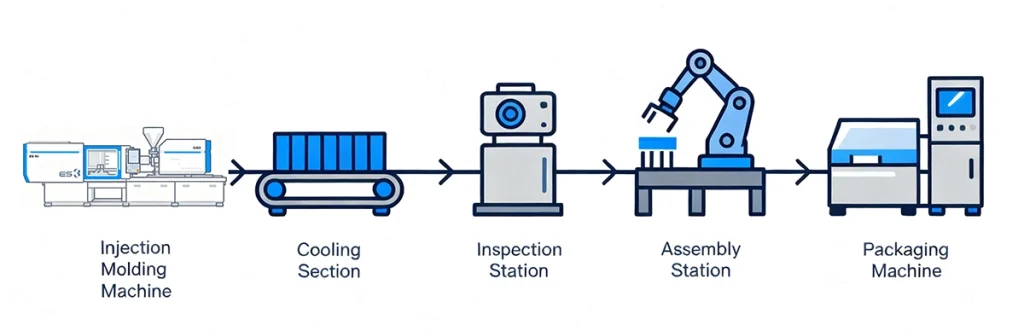

The true value of a conveyor belt in injection molding is realized in its seamless integration into the entire production workflow, connecting discrete operations into a fluid system. It transforms the conveyor from a simple transport device into the central nervous system of the production floor, enabling data-driven monitoring and precise coordination. This transformation is what allows modern facilities to scale their automation, reduce unit costs, and maintain a competitive edge in precision molding.

From Mold to Stable Part: Initial Transport and Cooling

The first and most critical role begins at the moment of ejection. Belts immediately carry away parts that are still hot and susceptible to deformation. This transport is the first stage of cooling. Strategic belt selection here—such as using inclined designs to extend travel time or heat-resistant silicone belts for high-temperature materials—is essential for achieving uniform part geometry and preventing stress-related warpage.

Enabling Automated Quality Assurance

The conveyor becomes the backbone of the inspection cell. As parts move consistently under fixed cameras or sensors, flaws are detected automatically. This setup allows for 100% inline inspection compared to sporadic manual checks, with non-conforming parts being ejected from the line without stopping production, thereby significantly reducing scrap and labor costs.

Facilitating Assembly and Final Packaging

Following cooling and inspection, belts deliver components to downstream stations. They ensure a steady, organized flow of parts to robotic arms for assembly or to automatic packaging systems. This synchronized handoff is key to eliminating bottlenecks and maximizing the overall equipment effectiveness (OEE) of the production cell.

Ensuring Upstream Material Supply

A reliable process requires a consistent material feed. Conveyors tasked with moving raw resins from drying hoppers or bulk containers to the molding machine’s feed throat help automate this initial step, mitigating the risk of material bridging or hopper starvation that can lead to cycle interruptions.

Advantages and Benefits

The integration of a well-suited conveyor system into an injection molding line delivers measurable operational advantages, transforming part handling from a utility into a source of competitive edge. It achieves this by systematically eliminating manual handling bottlenecks between the press and downstream operations, thereby stabilizing the production cycle. Furthermore, it safeguards the quality of molded components by minimizing human contact and preventing handling-related damage, directly reducing scrap rates.

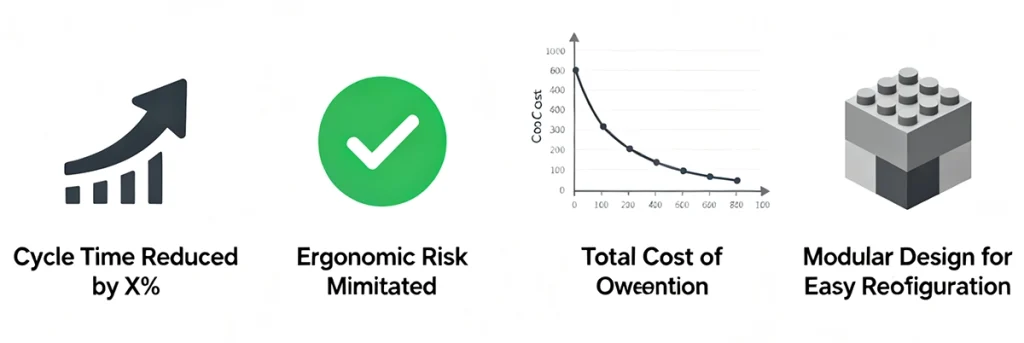

- Elevated Production Throughput

Automating the transfer of parts from the molding machine directly contributes to a reduced cycle time. This continuous, automated removal allows the press to operate at its established optimum cycle, eliminating delays associated with manual intervention. The result is a significant increase in overall equipment effectiveness (OEE) and a higher, more consistent output rate. - Strengthened Workplace Safety

Conveyor systems mitigate key ergonomic risks by eliminating the need for operators to manually handle hot, sharp, or heavy components. This automation directly reduces the potential for strain injuries and contact with post-mold parts, fostering a safer work environment and aiding compliance with industrial health and safety standards. - Optimized Lifetime Cost of Operation

The initial investment in a robust conveyor system is offset by long-term gains in operational efficiency. This includes reduced direct labor for part handling and lower downtime. Systems with modular designs, for instance, further decrease maintenance costs by enabling rapid replacement of individual sections without halting the entire line. - Adaptability to Production Demands

Modern conveyor belts are engineered to meet specific production challenges. Designs are available for demanding conditions, including cleanrooms, high-humidity environments, or the transport of abrasive materials. This ensures long-term reliability and allows the production line to be reconfigured or scaled to accommodate new parts or increased volume with minimal disruption.

A conveyor system that aligns with production requirements functions not as a standalone component, but as an integral element of a streamlined manufacturing process, directly contributing to sustained productivity and cost management.

Selection Guide

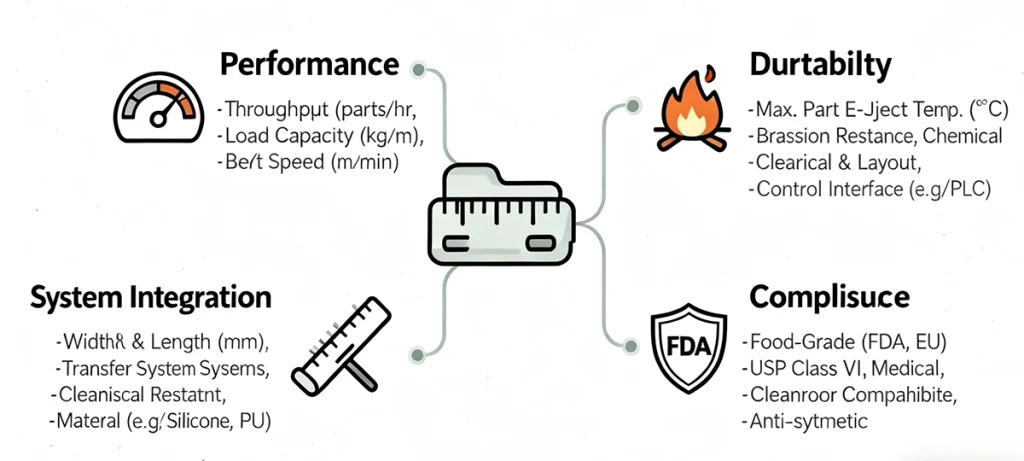

Specifying a conveyor belt that aligns with production requirements involves a systematic assessment of mechanical, thermal, and environmental factors. This framework outlines the key parameters for a technical evaluation.

- Dynamic Performance: Speed and Load Capacity

The belt’s mechanical specification must correspond to the line’s output speed and the combined weight of parts and runners. For high-cycle molding machines, belts with a high-tensile polyester core provide the necessary dimensional stability to resist stretching and maintain precise tracking under continuous operation. - Thermal and Mechanical Durability

Parts molded at temperatures ranging from 100°C to 200°C require belts made of heat-resistant materials such as silicone or specially compounded rubber. In applications involving abrasive materials, thicker belts with wear-resistant covers can reduce surface degradation, significantly extending the life of the conveyor belt. - System Integration and Physical Dimensions

The belt must seamlessly integrate with the molding machine’s discharge and downstream equipment. Critical physical dimensions (width, length, and thickness) are determined by available space, required flow rates, and the specific path the conveyor must take. - Environmental and Regulatory Compliance

Production environments dictate material choices. Facilities molding food-grade or medical components require belts made from non-toxic, corrosion-resistant polyurethane (PU) that comply with FDA or other relevant standards. In settings with high particulate or chemical exposure, sealed or coated belt designs help maintain product integrity by preventing contamination.

A methodical review grounded in these parameters provides a reliable path to specifying a conveyor system that supports both immediate production targets and long-term operational reliability.

Sustaining Performance: Installation and Operational Longevity

Proper installation and systematic maintenance are fundamental to achieving the designed service life and operational reliability of a conveyor belt. A disciplined approach to these practices directly influences production continuity and total cost of ownership.

Installation: Establishing a Foundation for Reliability

Precise alignment of the belt with all pulleys and drive components is critical to prevent tracking issues from the outset. Correct initial tensioning, as specified by the manufacturer, establishes the baseline for performance: insufficient tension leads to slippage, while excessive tension induces premature wear on bearings and the belt itself. The integration of physical guards and emergency stop functions is a mandatory step for operational safety and regulatory compliance.

Systematic Maintenance: Preserving Functional Integrity

A scheduled inspection routine should monitor for signs of wear, including edge damage, material tears, and tracking misalignment. Regular removal of accumulated debris prevents belt damage and product contamination. Cleaning protocols must utilize solutions compatible with the belt material—for instance, neutral pH detergents for polyurethane (PU) belts—to avoid chemical degradation. In modular belt systems, prompt replacement of individual damaged segments localizes maintenance and minimizes downtime.

Proactive Care and Operator Awareness

Beyond scheduled checks, visual monitoring for material fatigue—such as surface glazing, cracking, or edge wear—allows for the proactive planning of corrective actions. Furthermore, equipping operational personnel with the knowledge to identify early warning signs, like unusual noises or tracking drift, enables timely interventions that prevent minor issues from escalating into major production stoppages.

Adherence to a structured maintenance protocol not only extends the functional lifespan of the conveyor system but also safeguards its contribution to a stable and efficient production line.

Conclusion

The conveyor belt functions as the critical link that integrates ejection, cooling, quality control, and material handling into a cohesive automated system. Its technical specification and integration directly govern production line reliability, final product quality, and overall operational efficiency.

A methodical approach—grounded in a thorough understanding of belt types, application requirements, and specification parameters—provides a reliable framework for equipment selection. When these technical considerations are aligned with specific production demands, the conveyor system evolves from a peripheral utility into a core contributor to manufacturing throughput and stability.

For operations focused on optimizing their injection molding line, a detailed evaluation of the current conveying solution represents a logical and valuable step. The principles outlined in this article provide a substantive foundation for initiating such a technical assessment.

Let’s Develop Your Optimized Solution Together

Talk to our technical team to jointly create a conveying system that meets your precise technical and operational requirements.