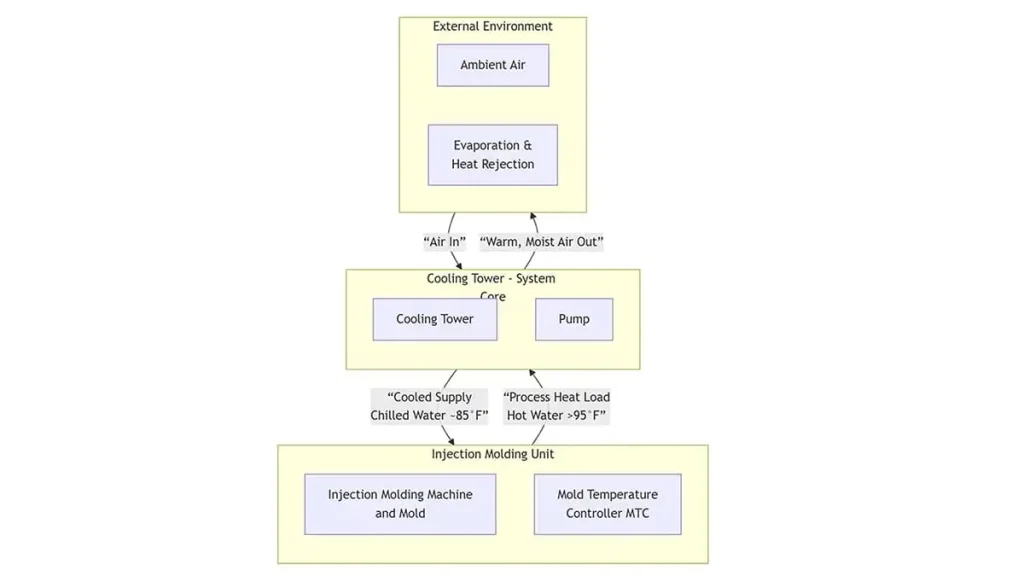

Injection molding is fundamentally a heat management process. During production, molten polymer at elevated temperatures is injected into a mold cavity, where it must be uniformly cooled and solidified prior to ejection. The performance of the cooling system is therefore critical to the entire operation.

The core function of a cooling tower in this context is heat rejection. It achieves this by removing thermal energy from the water circulating through two primary systems: the Mold Temperature Controllers (MTCs) responsible for mold cooling, and the hydraulic power units of the injection molding machines themselves. An optimally performing cooling tower delivers direct and measurable benefits across the production line:

- Dimensional Stability and Part Quality: Consistent and precise mold temperature control is paramount. It prevents common defects such as warpage, sink marks, and variations in internal stress, ensuring repeatable part dimensions and mechanical properties from the first shot to the last.

- Enhanced Production Efficiency: The cooling phase often constitutes the longest segment of the injection molding cycle. By facilitating more rapid heat extraction from the plastic, an efficient cooling system directly shortens this phase, enabling increased cycle rates and higher production throughput.

- Extended Machinery Service Life: Hydraulic systems operate within specific temperature ranges. A reliable cooling tower maintains hydraulic oil at its optimal temperature, reducing the risk of overheating, premature degradation of seals and components, and unplanned production stoppages.

- Reduced Operational Expenditure: Cooling towers operate on the principle of evaporative cooling, which is significantly more energy-efficient than the mechanical refrigeration used in chillers. By handling the primary heat load, a cooling tower lowers the runtime and energy consumption of ancillary chillers, leading to considerable savings in electrical costs.

In essence, a correctly specified and well-maintained cooling tower is not merely an auxiliary component but a foundational investment that supports manufacturing productivity, product quality, and long-term operational reliability.

What is a Cooling Tower and How Does It Work?

A cooling tower functions as an industrial-scale heat rejection device, operating on the principle of evaporative cooling. Its primary role is to efficiently remove process heat and dissipate it to the atmosphere.

The operational cycle can be broken down into the following sequential phases:

- Hot Water Inlet: Process water, which has absorbed heat from the injection molding equipment (typically returning at temperatures around 35°C / 95°F), is pumped to the top of the cooling tower.

- Water Distribution: This warm water is evenly distributed across the “fill” media—a structured lattice designed to create a large surface area by spreading the water into thin films or fine droplets.

- Airflow Introduction: A mechanically induced draft, created by one or more powerful fans, forces or draws ambient air through the falling water film within the fill.

- Evaporative Heat Transfer: As air and water come into direct contact, a small portion of the water evaporates. This phase change from liquid to vapor consumes a significant amount of latent heat, which is extracted from the remaining water mass, thereby reducing its temperature.

- Cooled Water Collection: The cooled water (now approximately 29°C / 85°F under standard conditions) descends into the cold water basin, ready to be recirculated back to the process.

- Concentration Control (Blowdown): Due to continuous evaporation, dissolved solids in the water become concentrated. To maintain water quality and prevent scaling, a controlled portion of this concentrated water is discharged as “blowdown” and replaced with fresh make-up water.

This closed-loop cycle provides a highly efficient and sustainable method for continuous heat rejection in injection molding operations.

Cooling Tower Designs and Specification Guidance

In injection molding, the protection of the cooling circuit is paramount. Contaminants like scale, corrosion, and algae in the cooling water can clog fine cooling channels in the mold, leading to significant production downtime and costly tooling repairs. Consequently, Closed Circuit Coolers are the standard and recommended solution for primary process cooling. However, understanding all technologies provides context for this specification.

The Standard for Primary Process Cooling: Closed Circuit Coolers

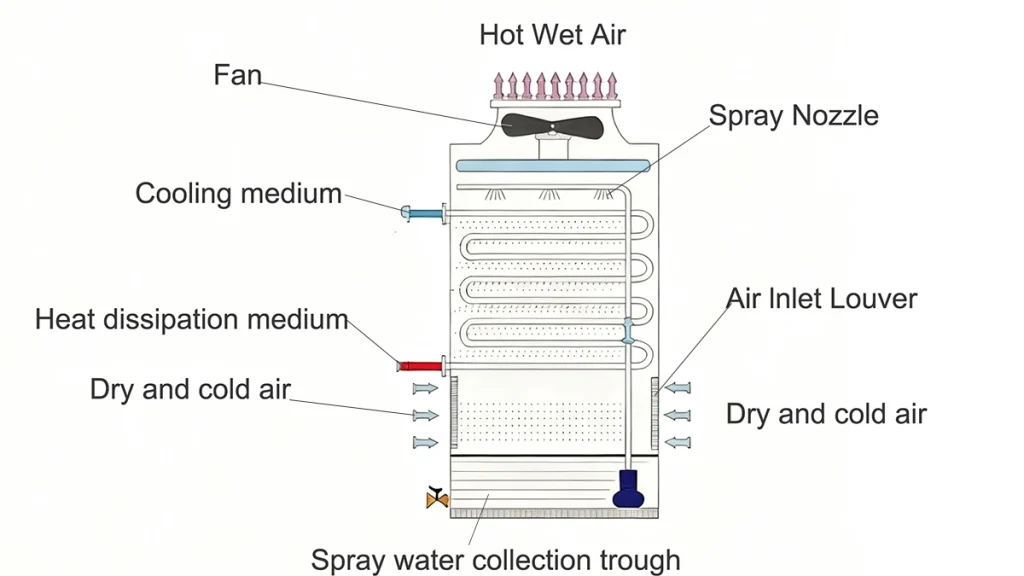

- Operation & Principle: Often called fluid coolers, these systems feature a sealed coil bundle through which the primary process coolant circulates. This clean, closed loop is entirely isolated from the atmosphere. Heat is rejected when a separate spray of water is evaporated over the exterior of the coils, cooling the internal fluid without any contact.

- Why it’s the Preferred Choice for Molding:

- System Protection: The sealed loop is the core advantage. It safeguards expensive molds and hydraulic system components from scale, corrosion, and clogging, ensuring consistent cooling performance and product quality.

- Reduced Maintenance: By keeping the process water clean, the demand for water treatment chemicals and system flushing is drastically reduced.

- Operational Stability: Provides reliable, consistent temperature control, which is critical for dimensional stability and cycle time repeatability.

- Consideration: The initial investment is typically higher than that of an open tower of comparable capacity, and the heat transfer efficiency is marginally lower due to the secondary heat exchange process.

Open Circuit Cooling Towers: A Niche Application

- Operation & Principle: In this design, the process water itself is pumped directly to the tower, distributed over the fill media, and cooled through direct contact and evaporation with the ambient air.

- Inherent Challenges for Injection Molding: This exposure makes the system water vulnerable to atmospheric contamination, concentration of dissolved solids (scaling), and biological growth. These factors pose a direct risk to the intricate cooling channels of an injection mold.

- Potential Application Context: If used at all in a molding facility, open towers are typically relegated to non-critical secondary loops, such as pre-cooling water for a closed-circuit system or cooling other plant equipment where water purity is not a concern. Their use mandates an exceptionally rigorous and well-managed water treatment program.

Configurations Within Closed Circuit Systems: Induced vs. Forced Draft

The choice between induced and forced draft designs remains relevant within closed-circuit coolers, primarily impacting serviceability and footprint.

- Induced Draft (Typical): The fan is located at the top, pulling air through the unit. This often provides more uniform air distribution and stable performance, with reduced risk of exhaust air recirculation.

- Forced Draft (Alternative): The fan is at the base, pushing air. This places the motor and fan in an easy-to-access, dry location for maintenance, which can be a deciding factor for some facilities.

Conclusion

In summary, the cooling tower transcends its role as a mere utility and functions as a critical asset for strategic production control in injection molding. Its performance directly governs key outcomes in part quality, cycle time, machinery longevity, and operational cost.

A thorough understanding of its operation and the available technologies, as outlined in this article, provides the foundation for making a capital investment that aligns with long-term manufacturing objectives. The choice of a cooling system warrants careful consideration of your specific thermal load, facility constraints, and quality standards.

PlasticMech specializes in the application of thermal management systems for plastics manufacturing. Should you require assistance in translating these technical considerations into a specification, our engineering team is available to support your evaluation process.

Ready to optimize your cooling process?

Contact the PlasticMech team today for a personalized consultation.