The Automation Imperative in Plastics Manufacturing

Today’s plastics manufacturers face a perfect storm of challenges: a shrinking skilled labor pool, relentless demands for higher quality, and the pressure to manage costs amid shorter production runs. In this environment, automation isn’t just a strategic choice—it’s the most effective pathway to operational resilience.

Key Automation Benefits: Robotic systems for injection molding offer a proven solution. Their impact is tangible: many manufacturers report significant reductions in cycle times, minimized scrap and material waste, and an accelerated return on investment, often realized within 12 to 18 months.

However, the path to automation is not one-size-fits-all. While the benefits are clear, the critical decision lies in choosing the right robot for your specific application. This choice, particularly between a 3-axis and a 5-axis system, requires a detailed analysis of your part complexity, production volume, and long-term business goals. This guide cuts through the technical jargon to help you navigate this decision and secure a lasting competitive advantage.

Understanding 3-Axis and 5-Axis Robots

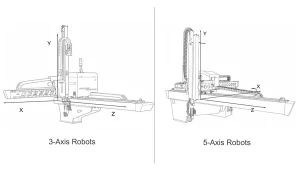

Figure 1: Movement capabilities of 3-axis vs 5-axis injection molding robots

Technical Differences in Motion Range and Degrees of Freedom

The core distinction between these two robot classes lies in their degrees of freedom—the independent movements they can execute in a three-dimensional space. This difference directly determines their operational flexibility, application suitability, and overall cost.

3-Axis Robots:The Straightforward Workhorse

A 3-axis robot is designed for linear, high-speed movement along three perpendicular axes:

- X-axis: Horizontal travel (left to right)

- Y-axis: Transverse travel (front to back)

- Z-axis: Vertical travel (up and down)

With its direct, linear path, this robot is an ideal solution for basic tasks like rapid part removal, sprue picking, and straightforward stacking. Its simple mechanical design and intuitive programming, typically done with a user-friendly teach pendant, make it highly efficient for repetitive operations with minimal part complexity.

5-Axis Robots: The Articulated Specialist

Building upon the linear capabilities of a 3-axis system, a 5-axis robot adds two rotational axes, giving it the dexterity of a human wrist:

- X, Y, Z Axes: The same linear movements as a 3-axis robot.

- A-axis: Rotational movement around the X-axis.

- B-axis: Rotational movement around the Y-axis.

This added articulation allows the robot to perform complex, multi-plane operations. It can reach around obstacles, reorient parts with precision for downstream processes, or perform intricate in-mold tasks like insert placement or de-gating. While its programming requires more advanced knowledge, often using offline simulation, its versatility unlocks new levels of automation for complex part manufacturing.

3-Axis and 5-Axis in Detail

The correct robotic specification is based on measurable performance metrics and critical operational factors related to your production environment.

3-Axis Robot Advantages

- Lower initial cost

- Simple to program and operate

- Reduced maintenance requirements

- Compact footprint

- Faster implementation

- Ideal for simple, repetitive tasks

3-Axis Robot Limitations

- Limited to linear movements

- Cannot handle complex parts

- Less adaptable to product changes

- Potential for longer cycle times

- Limited ability for secondary operations

- May require additional downstream equipment

5-Axis Robot Advantages

- Superior flexibility

- Handles intricate part geometries

- Performs multiple operations in one cycle

- Better space utilization

- Adaptable to product changes

- Faster cycle times for complex tasks

5-Axis Robot Limitations

- Higher initial investment

- More complex programming requirements

- Increased maintenance costs

- Requires more skilled operators

- Longer training period

- Potential overkill for simple tasks

Not Sure Which Robot Type Fits Your Production Needs?

Our team of automation specialists can analyze your specific manufacturing requirements and recommend the optimal robot configuration.

Real-World Impact: Case Studies with Quantifiable Results

To illustrate how these technical differences translate into real-world business outcomes, we’ve analyzed two case studies with distinct manufacturing challenges and successful robotic solutions.

Case Study 1: Automotive Supplier Achieves 22% Cycle Time Reduction

Challenge: A tier-one automotive supplier needed to improve consistency and cycle times for complex dashboard components that required the precise placement of multiple inserts. Manual intervention was leading to quality control issues and production bottlenecks.

Solution: Implemented 5-axis injection molding robots for high-precision insert placement and part extraction.

Results:

- Overall cycle time was reduced by 22%.

- Scrap rate dropped from 3.8% to just 0.7%.

- Labor costs were cut by 35%.

- ROI was achieved in 14 months, even with the higher initial investment.

Key Insight: For high-complexity applications with intricate part geometries and secondary in-mold operations, the superior articulation and precision of a 5-axis robot can significantly streamline the entire production process and deliver a rapid return on investment.

Case Study 2: Medical Device Manufacturer Optimizes with 3-Axis Solution

Challenge: A medical device manufacturer needed to automate the production of simple syringe components. The primary goals were to meet strict quality standards, improve handling consistency, and minimize capital expenditure.

Solution: Implemented 3-axis injection molding robots with an integrated vision inspection system.

Results:

- Cycle time was reduced by 15%.

- The system enabled 100% part inspection with automated rejection.

- Consistent handling completely eliminated contamination issues.

- ROI was achieved in just 9 months.

Key Insight: This case demonstrates that for applications with simple part geometries and standard removal tasks, a well-implemented 3-axis robot provides all the necessary functionality at a significantly lower cost, delivering a faster ROI.

“The decision between 3-axis and 5-axis robots isn’t about which technology is superior—it’s about which solution best matches your specific manufacturing challenges and production goals.”

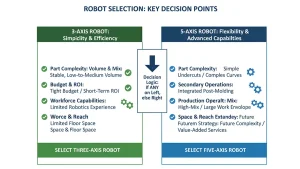

How to Select the Right Robot for Your Factory

Figure 2: Choosing Between 3-Axis and 5-Axis Robots

Step-by-Step Selection Checklist

Making the right investment in automation requires a systematic approach. Use this checklist to evaluate your factory’s specific needs and identify the robot that will deliver the best performance and long-term value.

1. Analyze Part Complexity

- Catalog all part geometries in your production line

- The presence of undercuts, complex curves, and difficult-to-reach features

- Whether parts require manipulation at various angles

- Consider future product development plans

- Recommendation: 5-axis for complex geometries; 3-axis for simple parts

2. Evaluate Production Volume

- Calculate annual production requirements

- Determine batch sizes and changeover frequency

- The cycle time requirements needed to meet demand

- Consider seasonal fluctuations in production

- Recommendation: 5-axis for high-mix, high-volume; 3-axis for consistent, simple production

3. Budget Considerations

- Calculate total available investment capital

- Determine acceptable ROI timeline

- Include programming and training costs

- Factor in maintenance and operational expenses

- Recommendation: 3-axis for tighter budgets with faster ROI requirements

4. Space Constraints

- Measure available floor space around injection molding machines

- Consider ceiling height limitations

- Evaluate robot reach requirements

- Plan for safe operator interaction zones

- Recommendation: 3-axis for tighter spaces; 5-axis when reach is more important than footprint

5. Workforce Capabilities

- Assess current team’s programming expertise

- Evaluate maintenance team’s technical capabilities

- Consider training requirements and timeline

- Plan for potential staffing changes

- Recommendation: 3-axis for teams with limited robotics experience

6. Secondary Operations

- List all post-molding operations currently performed

- Identify operations that could be automated

- Calculate labor savings from integrated operations

- Consider quality improvements from automation

- Recommendation: 5-axis for integrating multiple operations in one cycle

Expert Tip: When evaluating 3-axis and 5-axis robots, consider your five-year production roadmap. If you anticipate increasing part complexity, a shift to higher-mix production, or the addition of more value-added services, investing in a 5-axis robot may offer better long-term value, despite the higher initial cost. This is an investment in your factory’s future capacity.

Future-Proofing Your Investment: Emerging Trends & Solutions

A truly strategic investment in automation looks beyond a robot’s immediate capabilities and considers its long-term potential. Staying informed on emerging trends is key to ensuring your investment remains relevant and valuable for years to come.

Smart Automation and Connectivity

The next leap in robot performance comes from the integration of data and intelligence. Both 3-axis and 5-axis robots are now at the center of this evolution.

AI-Driven Predictive Maintenance

The latest systems use AI algorithms to analyze operational data, allowing them to predict potential failures before they occur. This proactive approach can reduce unplanned downtime by up to 50% and extend the robot’s service life by 15-20%, ensuring maximum uptime and efficiency.

IoT Integration for Real-Time Monitoring

Robots with IoT connectivity provide a continuous stream of real-time data on performance, diagnostics, and production metrics. This real-time insight empowers manufacturers to optimize processes, troubleshoot remotely, and make data-driven decisions that improve overall productivity.

Flexible and Modular Solutions

The trend toward shorter production runs and higher product variety demands automation that can adapt quickly without a complete overhaul.

Hybrid Solutions: Upgrading Existing Equipment

Manufacturers with a fleet of 3-axis robots don’t always need to start from scratch. Modern retrofit packages can inject new life into existing equipment through modular additions:

Smart Sensor Packages

Aftermarket sensors provide enhanced capabilities like advanced part presence detection, vibration monitoring, and force feedback for better handling.

Controller Upgrades

A modern control system can boost performance with improved motion control and simplified programming interfaces, bringing older robots up to modern standards.

Collaborative Robot (Cobot) Options

The rise of cobots, available in both 3-axis and 5-axis configurations, offers a new level of flexibility. These systems can operate safely alongside human workers without extensive safety barriers, creating agile work cells for mixed manual and automated operations.

Future-Proofing Consideration: When selecting between 3-axis vs 5-axis injection molding robots, ensure your vendor offers upgrade paths and retrofit options. The ability to enhance capabilities through software updates and modular hardware additions can significantly extend the useful life of your automation investment.

Conclusion

Strategic automation planning with expert consultation leads to optimal results

The decision between a 3-axis and a 5-axis injection molding robot is more than a technical choice; it’s a strategic investment that will define your factory’s capabilities and competitiveness for years to come. While a 3-axis robot can deliver rapid, cost-effective gains for straightforward applications, a 5-axis system offers the flexibility to handle complex parts and adapt to future production demands.

Ultimately, the key to a successful implementation is a partnership with experienced automation specialists. These experts can help you navigate the complexities of your specific challenges, ensuring you make an informed decision that aligns with your long-term goals.

“The ROI of automation isn’t just measured in cycle time reduction or labor savings—it’s about creating manufacturing capabilities that were previously impossible, opening new market opportunities and ensuring competitiveness for years to come.”

By using the practical framework provided in this guide, you are now equipped to carefully evaluate your unique requirements. Remember, the best solution isn’t simply the most advanced technology; it’s the one that most closely aligns with your specific needs. With the right guidance, this investment will become a cornerstone of your future success.

How long does implementation typically take for each robot type?

The implementation timeline can vary based on your specific application and line integration. Generally, a 3-axis robot requires 2-4 weeks from delivery to full production. A 5-axis robot typically requires a longer timeline of 4-8 weeks due to the added complexity of programming and operator training for advanced applications.

Can I upgrade from a 3-axis to a 5-axis robot later?

While direct upgrades are rarely possible due to fundamental design differences, many manufacturers offer trade-in programs. The better approach is often to select a 3-axis robot with the controller capability to support additional robots in the future, allowing for phased automation expansion.

Ready to Optimize Your Injection Molding Operations?

Our team of automation specialists can conduct a comprehensive analysis of your production requirements and recommend the optimal robot configuration for your specific needs.