What Are Plastic Pellets? Types and Key Specifications

Plastic pellets, also known professionally as thermoplastic granules or resin pellets, are the standardized primary feedstock that drives the injection molding process. Typically sized between 2 mm and 5 mm in diameter, this precise uniformity is foundational to efficient processing. In the hopper and screw assembly of your injection machine, consistent pellet size guarantees both accurate dosing precision and homogeneous melting. This consistency is the starting point for predictable material flow and, ultimately, defect-free parts throughout the entire molding cycle.

Common Types of Plastic Pellets for Injection Molding

Effective material selection begins with understanding the core application demands. Resins are broadly segmented into two families, each requiring specific machine setup and thermal management:

Commodity Thermoplastics

| Resin | Key Characteristics for Molding | Note on Structure |

| Polyethylene (PE) | Excellent chemical and moisture barrier properties. Low viscosity requires careful control of holding pressure. | Semi-Crystalline: Exhibits higher, directional shrinkage. |

| Polypropylene (PP) | Excellent fatigue resistance (ideal for living hinges) and low density. Highly versatile but prone to warpage if cooling is uneven. | Semi-Crystalline: Requires precise mold temperature management. |

| Polystyrene (PS) | Offers clarity and excellent processability (good flow). Cost-effective for non-structural applications. | Amorphous: Offers lower, more predictable shrinkage. |

| Polyvinyl Chloride (PVC) | Naturally flame retardant and chemically resistant. Requires specialized equipment (corrosion resistance) due to high processing temperatures. | Amorphous/Flexible Grades |

Engineering Thermoplastics

| Resin | Key Characteristics for Molding | Processing Insight |

| ABS | Excellent balance of strength, impact resistance, and surface finish. Popular for robust housings and complex geometries. | Amorphous: Lower mold temperature often suitable. |

| Polycarbonate (PC) | Exceptional impact strength and optical clarity. Highly hygroscopic; requires rigorous predrying to prevent hydrolysis (material breakdown). | Amorphous: Demands high processing temperatures. |

| Polyamide (Nylon – PA) | High mechanical strength, excellent wear, and thermal resistance. Often used for load-bearing parts. | Semi-Crystalline: Sensitive to moisture absorption (post-molding dimensional change). |

| Polyethylene Terephthalate (PET) | Excellent stiffness and barrier properties. Requires consistent mold temperature for proper crystallization. | Semi-Crystalline: Used for bottles and high-performance fibers. |

Crucial Note on Compounding

Many pellets are sold as compounds, pre-mixed with additives (e.g., glass fibers for stiffness, UV stabilizers) or masterbatches (colorants). These components critically affect the resin’s final melt viscosity and abrasiveness on the screw and barrel.

Technical Specifications for Processing

These specifications are the data points engineers use to program the injection cycle, ensuring material behavior matches product requirements:

| Property | Description | Measurement Unit | Direct Significance for Injection Molding |

| Melt Flow Index (MFI) | Mass of polymer extruded through a standard die in 10 minutes under specified load and temperature. | g/10 min | Flowability. Directly informs required injection pressure and filling speed. Higher MFI = lower viscosity = easier mold filling. |

| Density | Mass per unit volume. | g/cm³ | Affects part weight and the material’s specific heat, which influences the cooling duration and cycle time. |

| Heat Deflection Temperature (HDT) | Temperature at which a standard test bar deflects under a specified load. | °C | Determines the minimum safe ejection temperature from the mold, crucial for preventing part distortion and optimizing cycle speed. |

| Shrinkage Rate | Percentage of dimensional change as the material cools and solidifies within the mold cavity. | % | Critical for mold design. Semi-crystalline materials have higher shrinkage than amorphous materials. |

| Moisture Absorption | Percentage of water absorbed from the environment at standard conditions. | % | Drying Requirement. Dictates the necessary predrying time and temperature to prevent hydrolytic degradation and cosmetic defects like splay marks. |

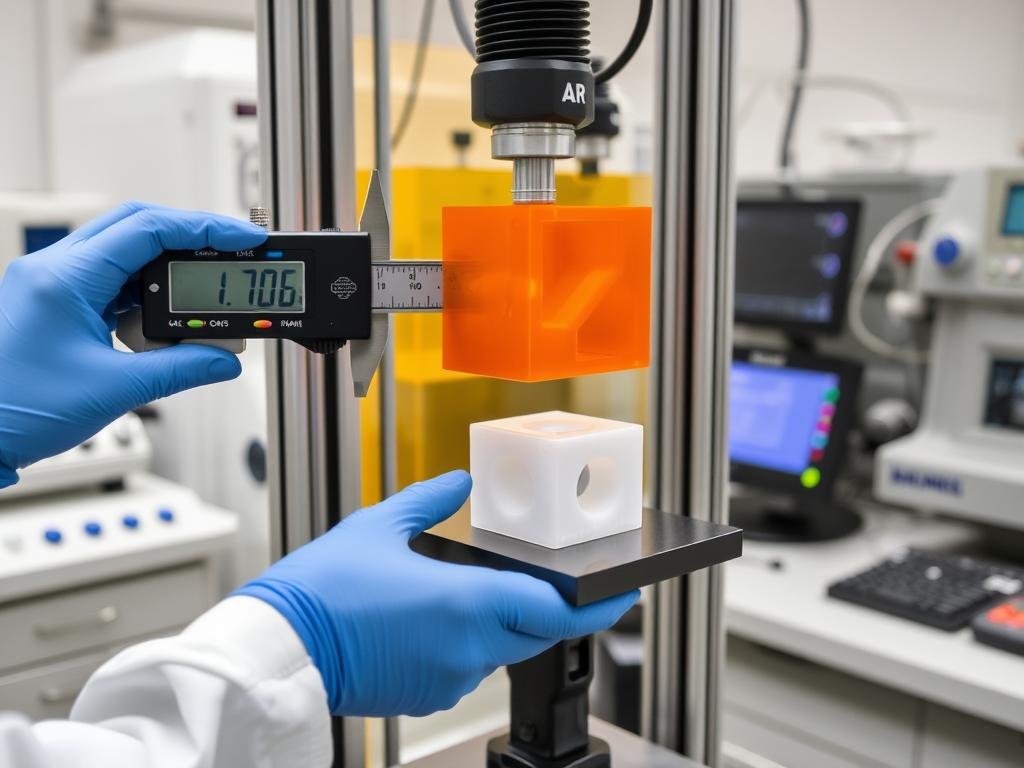

How Pellet Quality Impacts Molding Performance

The quality of plastic pellets is not merely a material concern; it is a process control variable that dictates the efficiency and success of every injection molding cycle. Understanding this relationship is crucial for engineers aiming to stabilize production parameters and maximize output reliability.

Processing Efficiency and Machine Dynamics

Consistent, high-quality plastic resin is the prerequisite for an optimized production line. Uniform size and shape minimize bridging in the hopper and guarantee stable dosing within the screw and barrel. This consistency directly reduces the necessary screw back pressure and prevents the metering instability that leads to shot-to-shot variations. Furthermore, clean material free from fines melts uniformly, leading to stable melt viscosity and the potential for reduced cycle time.

Part Quality and Defect Prevention

Pellet quality is visibly reflected in the finished product. Inconsistencies in the raw material directly translate into common, costly molding defects:

- Dimensional Integrity: Variations in composition create fluctuating melt flow, leading to deviations in dimensional stability and unacceptable tolerance drift.

- Surface Aesthetics: Improperly dried pellets cause hydrolysis during melting, resulting in visible splay marks (silver streaking). Foreign materials manifest as black specks or streaks.

Mechanical Properties and Long-Term Reliability

The final performance of the component is locked in at the molecular level of the pellet. Consistent molecular weight distribution and precise additive loading ensure that molded parts meet published specifications. Conversely, low-quality pellets introduce unpredictable variables, increasing the risk of premature part failure, warranty claims, and the high cost associated with scrap rate and unscheduled machine downtime.

Common Quality Issues and Their Effects

The contrast between optimal and problematic feedstock can be summarized by these essential distinctions:

High-Quality Pellet Characteristics

- Uniform size and shape for precise metering and feeding.

- Free from contamination, foreign materials, and excessive dust/fines.

- Consistent color and additive dispersion across the batch.

- Proper moisture content (typically < 0.1% or specified) to prevent hydrolysis.

- Consistent Melt Flow Index (MFI) and density for reliable processing.

- Secure packaging to prevent moisture ingress and degradation.

Low-Quality Pellet Issues

- Inconsistent size causing bridging and jamming in the feed system.

- High moisture content leading to splay marks and material degradation.

- Contamination resulting in visible defects like black specks or streaks.

- Excessive fines/dust creating unstable melting and thermal issues.

- Fluctuating MFI properties causing inconsistent fill patterns and packing.

- Improper storage leading to pre-molding plastic raw material degradation.

Optimizing processing settings is futile if the feedstock is inconsistent. Even the most advanced injection molding machine can only maximize the potential of high-quality pellets; it cannot stabilize poor material.

How to Select the Right Granules for an Injection Molding Machine

Determining the appropriate plastic resin for your injection molding process requires a systematic approach that considers both technical requirements and operational constraints. A structured framework is essential to evaluate trade-offs and avoid both over-engineering (wasting material cost) and under-performance (risking product failure). This approach helps ensure the optimal plastic pellets are accurately matched to both the product and the machine.

Technical Selection Criteria

Defining Product Constraints

The initial phase focuses on translating the part’s functional demands into measurable material properties:

- Mechanical & Structural Requirements: Precisely assess required tensile/yield strength, stiffness (Modulus), impact resistance (Izod/Charpy), and wear characteristics based on end-use loading conditions. This may also include Weight Reduction Goals.

- Thermal Performance: Determine the operational temperature envelope, including the required Heat Deflection Temperature (HDT), maximum service temperature, and thermal expansion compatibility.

- Environmental Durability: Evaluate resistance to specific chemicals, moisture absorption, UV degradation, and long-term creep under stress.

- Aesthetic & Finish: Define color specifications, required transparency/opacity, desired surface finish (e.g., gloss or texture), and mold release requirements.

- Regulatory Compliance: Mandatorily identify standards such as FDA (food contact), ISO (medical), UL (flame retardancy), and any relevant environmental regulations.

Processing Considerations

As a core process step, material choice must align with the capabilities of the injection molding machine and the mold tooling.

- Equipment Capacity Alignment: Match the material’s melt temperature and viscosity profile to the machine’s injection pressure and screw/barrel design. Critically, verify the material volume against the machine’s injection unit capacity and ensure part projection area matches the clamping force of the press.

- Tooling Dynamics: Factor in the material flow characteristics (MFI/viscosity) for mold filling. Account for high shrinkage rates (especially semi-crystalline materials) and the need for optimized cooling line placement.

- Cycle Time Objectives: Match materials with melt flow rates that facilitate efficient filling and require minimal cooling time to meet the target cycle time for cost objectives.

- Supply Chain & Sustainability: Confirm the material’s long-term availability, price stability, and compatibility with corporate sustainable goals (e.g., using post-consumer recycled (PCR) content).

Material Selection Decision Matrix

When evaluating multiple resin options, a weighted decision matrix provides a quantitative tool to identify the most commercially suitable option. This approach systematically balances critical technical performance against business constraints like cost and processability.

| Selection Criteria | Weight Factor (1-10) | Material A Score (1-10) | Material B Score (1-10) | Material C Score (1-10) |

| Required Mechanical Properties | 9 | 8 | 7 | 9 |

| Thermal Stability (HDT) | 7 | 6 | 8 | 7 |

| Chemical/Environmental Resistance | 8 | 9 | 6 | 7 |

| Processability & Cycle Time | 7 | 7 | 8 | 6 |

| Total Material Cost (Per Part) | 8 | 8 | 7 | 5 |

| Supply Chain/Availability | 7 | 9 | 7 | 6 |

| Weighted Total | – | 317 | 289 | 280 |

Material Selection Tip

Always request the full Technical Data Sheet (TDS) and Processing Guide from suppliers. Pay specific attention to the rheological data and drying protocols—this information is vital for accurately simulating mold flow and programming the injection machine’s settings for maximum efficiency.

Optimize Your Material Selection

Our technical team can help you evaluate material options and select the optimal plastic pellets for your specific injection molding application.

Troubleshooting Common Pellet-Related Molding Issues

Even with the correct plastic resin determined, material quality and handling can introduce costly processing instability. Effective troubleshooting requires a systematic approach to identify the root cause—whether it lies in material preparation, the feed system, or thermal management. Resolving these issues directly lowers your scrap rate and improves overall OEE (Overall Equipment Effectiveness).

Moisture-Related Defects

Symptoms: Surface splay marks

Cause: Excessive moisture content in hygroscopic plastic raw materials (e.g., PA, PC, PET).

Solution (Focusing on Equipment & Process): Implement precise drying using desiccant dryers with dew point monitoring to meet material specifications (typically 80-120°C for 2-4 hours). Use closed handling systems to prevent moisture reabsorption after drying.

Inconsistent Melt Flow

Symptoms: Inconsistent filling, short shots, flash, or variable part weight/dimensions.

Cause: Variation in pellet size, MFI, or mechanical issues in the feed/metering system.

Solution (Focusing on Machine Integrity): Check machine integrity: Inspect the non-return valve (check ring) on the screw for wear, which causes inconsistent shot size. Verify material consistency (MFI) with the supplier. Ensure consistent regrind percentage and proper blending with virgin material.

Degradation During Processing

Symptoms: Discoloration, burnt spots, odor, reduced mechanical properties (e.g., poor impact strength).

Cause: Excessive heat exposure or prolonged residence time

Solution (Focusing on Temperature Control): Optimize Machine Settings: Process at the lower end of the recommended temperature range. Reduce residence time by optimizing shot size to barrel capacity. Verify that your temperature control systems are calibrated and accurate. Purge thoroughly using a suitable purging compound during extended stops.

Contamination Issues

Symptoms: Black specks

Cause: Cross-contamination during material handling or residue from previous production runs.

Solution (Focusing on Handling & Cleanliness): Implement strict material segregation and cleaning protocols. Use dedicated hoppers and loaders. Purge the barrel completely between material or color changes using a high-quality purging agent. Consider specialized melt filtration systems for critical applications.

Practical Applications Across Industries

Plastic pellets for injection molding find applications across diverse industries, each with specific material requirements and performance criteria. Understanding these industry-specific applications provides valuable context for material selection and process optimization.

Automotive

- Interior Components: PP/TPO for dashboards and door panels, offering durability and chemical resistance

- Under-Hood Parts: Glass-filled nylon for high-temperature applications like coolant reservoirs

- Exterior Trim: ASA and PC/ABS blends providing UV stability and impact resistance

- Key Requirements Driving Material Selection:Thermal Stability (HDT), Impact Strength, Long-term UV Durability, Chemical Resistance (e.g., to fluids and cleaning agents).

Medical & Healthcare

- Diagnostic Equipment: PC and ABS for device housings requiring clarity and impact resistance

- Surgical Instruments: Medical-grade POM (acetal) for precision components

- Drug Delivery Systems: Medical-grade PP and PE for syringes and inhalers

- Key Requirements Driving Material Selection:Biocompatibility, Sterilization Resistance (Autoclave/Gamma), Traceability, and adherence to stringent regulatory standards (e.g., ISO 10993).

Consumer Electronics

- Device Housings: PC/ABS blends offering flame retardancy and aesthetic appeal

- Internal Components: PBT and POM for precision mechanical parts

- Connectors: Glass-filled PBT providing dimensional stability and electrical properties

- Key Requirements Driving Material Selection:Flame Retardancy (UL94 V-0), Thin-Wall Flow Capability (demanding high-speed injection), Aesthetic Quality, and EMI/RFI shielding readiness.

Industrial & Packaging

- Pallets

- Crates

- High-Performance Closures (HDPE, LDPE)

- Key Requirements Driving Material Selection:Load-Bearing Strength, Stress-Crack Resistance, and High-Volume Consistency (demanding excellent cycle-to-cycle repeatability from the machine).

Emerging Trends in Plastic Pellets for Injection Molding

The landscape of plastic raw materials for injection molding is in constant evolution. Driven by sustainability, performance, and efficiency, these emerging trends redefine material science and necessitate corresponding advancements in injection molding machine capabilities and process control. Understanding these shifts is crucial for manufacturers to remain competitive and strategically plan for future production.

Sustainable Materials

The drive for a circular economy is pushing the frontier of plastic resin development:

- Bio-Based Polymers: Derived from renewables. Requires precise thermal control due to narrow processing windows.

- Recycled Content Pellets (PCR/PIR): Use post-consumer/industrial content; demand consistency in melt flow for predictable machine behavior.

- Biodegradable Options (PLA/PHA): Offer environmentally responsible end-of-life. May demand specialized screw designs to prevent degradation during processing.

- Carbon Footprint Reduction: Formulations optimized for lower melt temperatures, reducing the energy footprint of the plasticizing unit.

Advanced Formulations

Material science continues to unlock unprecedented functional capabilities:

- High-Performance Composites: Fiber-reinforced plastic pellets (e.g., carbon/glass) offer metal-like properties, demanding abrasion-resistant screws and higher injection pressures.

- Specialty Additives: Integrate advanced functions like antimicrobial properties, electrical conductivity, and enhanced flame retardancy (e.g., halogen-free).

- Multi-Material Solutions: Engineered for overmolding and multi-component injection, leveraging sophisticated multi-barrel machines.

- Custom Colorants: Advanced masterbatch formulation for highly consistent and stable custom colors.

Processing Innovations

The evolution of plastic pellets is intrinsically linked to smarter processing methods:

- Rapid Heat/Cool Molding (RHCM): Materials optimized for rapid mold surface changes, requiring precision mold temperature control units (TCUs) integrated with the machine.

- Low-Pressure & Thin-Wall Molding: Specialized plastic resins enable thin-wall components with reduced clamping force, testing the limits of injection speed and precision.

- Industry 4.0 Integration: “Smart” materials optimized for real-time process monitoring, enhancing quality control directly from the injection molding machine’s control system.

- Energy-Efficient Processing: New low-melt-temperature formulations significantly reduce the energy consumption of the machine’s plasticizing unit.

Industry Insight

The demand for sustainable plastic pellets is projected to grow at a CAGR of 9.8% through 2028. Manufacturers who proactively adapt to these material options, supported by optimized injection molding equipment and expertise, will gain significant competitive advantages in highly regulated and demanding markets.

Conclusion

Plastic pellets are a fundamental element that determines the success, efficiency, and ultimate cost structure of injection molding processes. Therefore, mastering the science of plastic raw materials is crucial for engineers and designers aiming to optimize product integrity and production efficiency.

Key Technical Takeaways:

- Systematic Determination: Material specification must follow a systematic evaluation framework that rigorously weighs product function, operational feasibility, and commercial constraints.

- Quality as Process Control: Pellet quality (uniformity, moisture, purity) is a critical variable that directly impacts machine dosing consistency and minimizes defects like splay marks and warpage.

- Application-Driven Design: Material requirements must be driven by rigorous analysis of industry-specific demands (e.g., medical biocompatibility, automotive heat deflection).

- Future Preparedness: Proactively integrating emerging trends in sustainable, high-performance plastic resins offers vital opportunities for innovation and market differentiation.

- Process Integrity: Effective troubleshooting of pellet-related issues requires precise knowledge of material rheology and proactive monitoring of machine thermal and pressure controls.

The challenge for manufacturers shifts from merely using the right material to mastering the synergy between the material and the machine. Only precise, reliable injection molding equipment can successfully manage the complexities of high-performance composites and inconsistent recycled content. Embracing continuous process refinement is the new standard for maintaining market leadership and competitive advantage.

Expert Material Selection Support

Our technical team specializes in helping manufacturers select and optimize plastic pellets for injection molding applications across industries. Contact us for personalized material recommendations, troubleshooting assistance, or custom formulation development.